Flexural Strength Testing

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Flexural Strength Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss flexural strength testing. Can anyone tell me what this testing is used for?

I think it checks how strong the concrete is when it's bent, right?

Exactly! Flexural strength testing helps us understand how well concrete pavements can handle bending forces. It's critical for ensuring our pavements remain durable. Do you remember what a typical specimen size is?

Isn't it 150 mm x 150 mm x 700 mm?

Correct! This dimension is essential to ensure consistency in testing. Now, why do you think we need to average the results from three specimens?

To get a reliable measure of strength and account for any variations?

Great point! Averaging helps us minimize the effects of any outliers. Let's remember this as 'Averaging Equals Accuracy'.

Third-Point Loading Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s dive into the method for determining flexural strength. What do you think 'third-point loading' means?

Is it where the force is applied at the third points of the beam instead of the center?

Exactly, Student_4! By applying force at the third points, we can create a moment that is distributed across the beam, allowing for more realistic testing. Why is this method preferred?

Maybe it mimics real-life situations more closely, like how cars drive over a pavement?

Exactly! You're both grasping the concept well. It’s crucial that our tests reflect actual usage conditions.

Acceptance Criteria

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s wrap up by discussing the results. What do you think we should do with the flexural strength results from our tests?

We should check whether they meet the minimum requirements set for the pavement design.

Right! Acceptance is based on the average of three specimens to ensure the quality of the concrete. This is a vital process in concrete mix design.

So, if one of the samples fails, it might still get accepted if the other two pass?

Good observation! That’s why averaging is so important; we need to confirm structural integrity. Remember this—'Consistency is Key in Testing'.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The focus is on the beam specimen dimensions used for testing flexural strength in concrete pavements, the methodology involving third-point loading, and the acceptance criteria based on the average strength of multiple specimens.

Detailed

Flexural Strength Testing

Flexural strength testing is essential for assessing the performance of concrete pavements. It involves using a beam specimen sized at 150 mm x 150 mm x 700 mm, as per IS 516 guidelines. The testing method typically utilized is the third-point loading method to determine the modulus of rupture (MOR) of the concrete beam. For acceptable results, the testing procedure requires an average of three specimens to determine the flexural strength, ensuring consistency and reliability in the results. This testing is crucial for architects and engineers to ensure that concrete pavements can withstand the expected loads and environmental conditions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Beam Specimen Dimensions

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

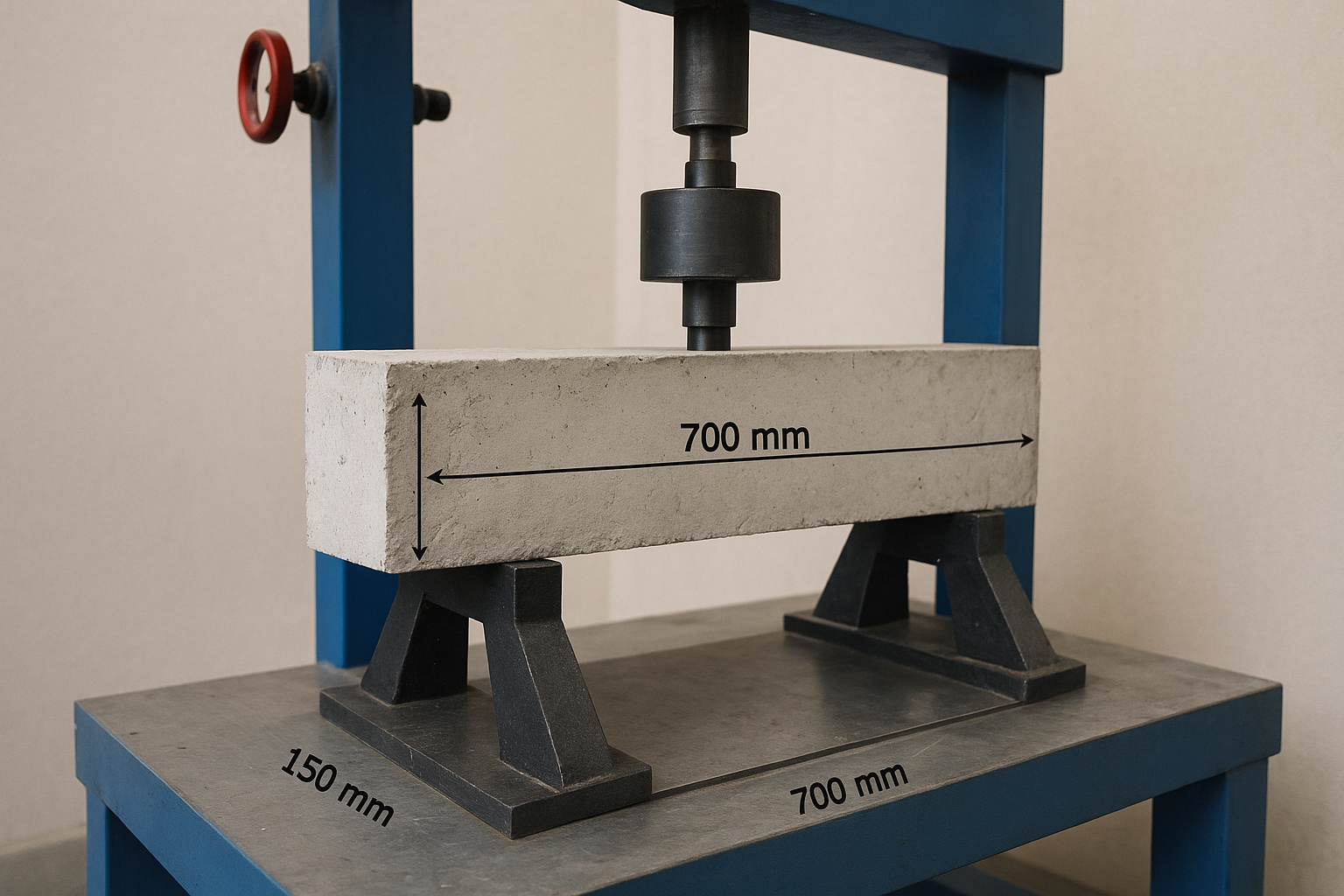

Beam Specimen: 150 mm × 150 mm × 700 mm (per IS 516).

Detailed Explanation

In flexural strength testing, the specimen used is a beam that has specific dimensions. According to the Indian Standard IS 516, the dimensions of the beam should be 150 mm in width, 150 mm in height, and 700 mm in length. These dimensions are standardized to ensure uniformity in testing and to achieve consistent results across different tests.

Examples & Analogies

Imagine a school using standardized test papers for all students to ensure fairness. Similarly, using standardized dimensions for the beam specimen allows for consistent testing conditions, ensuring that results are comparable.

Third-Point Loading Method

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Third-point loading method to calculate modulus of rupture (MOR).

Detailed Explanation

The third-point loading method is a specific technique used in flexural strength testing. In this method, a beam is supported at two ends, and a load is applied at two points located one-third of the distance from the ends. This loading setup creates bending in the beam, which allows for the calculation of the modulus of rupture (MOR). The MOR is a measure of the material's ability to resist failure under bending stress.

Examples & Analogies

Consider trying to break a stick by pushing down on it from its sides. If you press down in the center, it’s easier to snap. However, if you press down a third of the way from each end, the force distributes, making it a more accurate measure of how the stick can handle weight without breaking, similar to how the third-point loading method measures stress distribution in concrete beams.

Acceptance Criteria

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Acceptance based on average of three specimens.

Detailed Explanation

In order to determine the flexural strength of the concrete, multiple specimens are tested. The acceptance criteria stipulate that the final strength value is based on the average strength of at least three specimens. This approach helps ensure reliability and reduces the impact of any outliers or anomalies in testing results, providing a more accurate representation of the concrete's overall performance.

Examples & Analogies

Think of it like averaging test scores in a class to determine a student's performance. If one test was particularly hard and resulted in a low score, but other tests were easier, relying solely on a single score might misrepresent a student’s true abilities. By averaging, you get a clearer picture of performance, just as averaging the results of multiple concrete beams gives a more reliable measure of strength.

Key Concepts

-

Beam Specimen: Specimen is typically sized 150 mm × 150 mm × 700 mm for concrete testing.

-

Third-Point Loading: A method to distribute the applied load over a beam specimen for accurate testing of flexural strength.

-

Acceptance Criteria: Average results from multiple specimens are used to determine the acceptable strength.

Examples & Applications

A concrete beam measuring 150 mm x 150 mm x 700 mm is placed in a testing machine, and a load is applied at the third points to measure how much it bends before breaking, giving the modulus of rupture.

If three tests are performed and yield flexural strengths of 4.2 MPa, 4.5 MPa, and 4.8 MPa, the average flexural strength will be (4.2 + 4.5 + 4.8) / 3 = 4.5 MPa.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Testing concrete to find its might, Flexural strength in beams takes flight.

Stories

Imagine a race where beams compete to see whose strength holds up in the heat; one beam bends, but the others stand tall - the testing measures which one won it all.

Memory Tools

To remember the steps for testing flexural strength: Size (specimen), Three (load points), Average (results).

Acronyms

B.A.T - Beam size, Apply force at Thirds, Average results.

Flash Cards

Glossary

- Flexural Strength

The ability of a concrete specimen to resist deformation under load, typically measured as modulus of rupture.

- Modulus of Rupture (MOR)

A measure of the flexural strength of a material, denoting the maximum tension the material can withstand before failing.

- ThirdPoint Loading Method

A loading method where the load is applied at two third points along the span of a specimen.

- Beam Specimen

A tested specimen in a specific size used for determining the flexural strength of concrete.

Reference links

Supplementary resources to enhance your learning experience.