Step 6: Mix Calculations (Trial Mixes)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Mix Calculations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we'll dive into mix calculations for concrete. Can anyone explain why these calculations are essential?

They help ensure the concrete has the right strength, right?

Absolutely! Correct mix proportions impact not only strength but also workability and durability. We need to achieve the required performance standards through these calculations.

How do we know if our mix is right?

Great question! The mix needs to be validated through trial mixes and testing.

Conducting Trial Mixes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

When we prepare a trial mix, what factors do we test?

We test flexural strength and workability, right?

Exactly! We look at flexural strength, workability, air content, and other durability indicators. Each of these factors is crucial to ensuring the long-term success of the pavement.

And if the test doesn't meet our requirements?

Then we must adjust our mix proportions accordingly. It’s an iterative process.

Evaluating Mix Performance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Once we conduct our tests, how should we evaluate our results?

We compare the results to our target strengths and workability standards.

That's right! We also check if the durability tests meet requirements for freeze-thaw cycles and sulfate resistance.

What happens if it fails those tests?

If it fails, we go back and adjust our recipe to improve those characteristics. Continuous refinement is key!

Importance of Adjustments

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Why do you think making adjustments to our mixes is so important?

To ensure the concrete can withstand environmental conditions?

Exactly! Each environment can have unique challenges, and our mix must be robust enough to handle those.

So it's about creating a balance?

Yes! Balancing strength, workability, and durability is the heart of the mix design process.

Finalizing the Mix Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

What do we do after we've tested and made necessary adjustments?

We finalize the mix design for production?

Correct! The final design must adhere to all performance requirements, ensuring success in construction.

And we keep records of all tests and adjustments for future reference?

Yes! Documentation is vital for accountability and quality assurance.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The mix calculations in this section elaborates on the methodology for determining the correct proportions of concrete ingredients through trial mixes. It highlights the significance of adjusting mixtures based on field conditions and testing to ensure the concrete meets specified standards for performance attributes like strength and workability.

Detailed

Step 6: Mix Calculations (Trial Mixes)

In the design procedure of concrete mixes for pavements, Step 6 entails the critical process of calculating mix proportions. This phase involves determining the weight of each component required to achieve the desired properties of concrete. Trial mixes are created to fine-tune these proportions based on initial calculations. The following outlines the procedure:

- Objective of Trial Mixes: Trial mixes allow engineers to assess the concrete's performance in real-world scenarios before large-scale production.

- Adjustment Based on Results: It is essential to adjust the mix proportions as needed based on preliminary field conditions and laboratory test results.

- Testing for Performance: Each trial mix is subjected to various tests to evaluate:

- Flexural strength at 28 days, ensuring it meets design specifications.

- Workability, which is evaluated through slump tests.

- Air content, important for freeze-thaw resistance.

- Durability indicators such as sulfate resistance and abrasion tests.

Ultimately, these calculations and tests ensure that the final concrete mix will fulfill the specified performance criteria essential for durability and longevity in pavement applications.

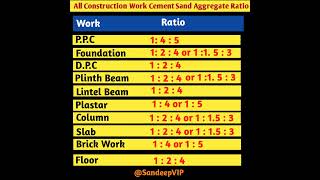

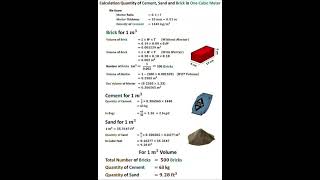

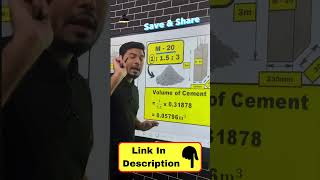

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Mix Proportions Calculation

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Compute mix proportions by weight.

Detailed Explanation

In this step, you need to calculate the proportions of each component of the concrete mix. This includes determining the precise weight of cement, aggregates, water, and any admixtures based on the desired mix design. The weight-based method is preferred because it provides greater accuracy compared to volume measurements, especially when dealing with different materials that might have varying densities.

Examples & Analogies

Think of it like following a recipe for baking a cake. Just as you measure flour, sugar, and eggs by weight for accuracy, you do the same with concrete materials to ensure the perfect mix for strength and durability.

Adjustments Based on Conditions

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Make adjustments based on field conditions and test results.

Detailed Explanation

After computing the initial mix proportions, adjustments may be necessary based on real-world conditions observed during trials. For example, if the initial mix is too dry and does not facilitate good workability, you might need to add more water or modify the aggregates used. Additionally, if test results indicate that the mix does not achieve the required strength, you may need to alter the quantity of cement or change the proportion of aggregates.

Examples & Analogies

Imagine adjusting a recipe after tasting the dish. If the cake is too dry, you might decide to add a bit more liquid. Similarly, in concrete mix design, adjustments are made based on the performance of the initial mix in practice.

Key Concepts

-

Trial Mix: A sample mix of concrete used to determine the performance characteristics before final production.

-

Flexural Strength: The resistance of a concrete beam to bending forces, critical for pavement design.

-

Workability: The measure of how easily concrete can be mixed, transported, placed, and finished.

-

Durability Testing: Evaluating concrete's resistance to environmental factors over time.

Examples & Applications

After mixing components in a trial, if the flexural strength is lower than expected, increase cement content or adjust the water-cement ratio to enhance strength.

A concrete mix initially shows high workability but fails the durability test; therefore, an air-entraining agent may be introduced to improve freeze-thaw resistance.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For strength to measure, we mix with pleasure, a trial we do for quality to treasure.

Stories

Imagine a baker who tries different flour mixes before baking a cake. Each trial tells him how to adjust to ensure the cake rises perfectly, just like concrete mixes are adjusted for optimal strength.

Memory Tools

Remember the ABCs of trial mixes: A - Adjust based on tests, B - Be mindful of workability, C - Check for strength.

Acronyms

SWEET

Strength

Workability

Environmental factors

Testing

Adjustments.

Flash Cards

Glossary

- Trial Mix

A preliminary mix created to test and adjust the proportions of concrete ingredients to achieve desired properties.

- Flexural Strength

The ability of a material to resist deformation under load, measured for concrete by loading a beam until it fails.

- Workability

The ease with which concrete can be mixed, placed, and finished, typically assessed through slump tests.

- Durability Indicators

Tests that assess concrete's ability to resist environmental factors and stresses over time, such as freeze-thaw cycles or sulfate attack.

Reference links

Supplementary resources to enhance your learning experience.