IRC:44 Method (Recommended by Indian Roads Congress)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to IRC:44 Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re diving into the IRC:44 Method. Can anyone tell me what the primary focus of this method is?

Is it about compressive strength?

Good guess, but the IRC:44 Method specifically emphasizes flexural strength, which is essential for pavements. Can you think of why flexural strength is more important for pavements than compressive strength?

Maybe because pavements face tension from traffic loads?

Exactly! Pavements are subjected to flexural stresses, making it crucial to focus on their flexural rigidity.

Importance of Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's talk about durability. What are some environmental factors that can affect concrete pavements?

Things like freeze-thaw cycles or sulfate exposure?

Correct! The IRC:44 Method incorporates these variables to ensure the mix is durable. How does durability relate to workability?

If the concrete is durable, it might be harder to work with?

Great point! There must be a balance to ensure that while the concrete is durable, it remains workable during the placement process.

Mix Design Process Steps

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's break down the mix design process according to the IRC:44 Method. What’s the first step?

Determining the target mean flexural strength?

Yes, correct! After that, how do we go about selecting the water-cement ratio?

Maybe based on the target strength and durability needs?

Exactly! Factors such as workability and the type of aggregates used also play a significant role in this step.

Trial Mixes and Adjustments

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Once we have our initial mix, what do you think is the next most critical step?

Preparing trial mixes and testing their properties?

Exactly! Testing for flexural strength and workability is crucial before finalizing the mix. Why do you think regular adjustments might be necessary?

Because the field conditions can change?

Exactly! Factors such as moisture content and temperature can significantly impact the fresh concrete's properties.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The IRC:44 Method is an essential guideline that emphasizes flexural strength as a crucial factor in concrete mix design for pavements. It incorporates durability and workability considerations, aligning with the specific demands of paved surfaces. This method is tailored to ensure optimal performance against environmental conditions and traffic loads.

Detailed

IRC:44 Method (Recommended by Indian Roads Congress)

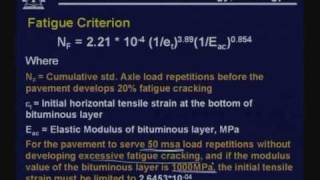

The IRC:44 method is specifically designed for pavements, emphasizing the importance of flexural strength (measured as the modulus of rupture) over traditional compressive strength measures. This approach accounts for the unique stresses that pavements face under traffic loads and environmental conditions.

Key components of the IRC:44 Method include:

1. Flexural Strength Focus: Pavements are evaluated primarily on their flexural strength due to their susceptibility to tensile stresses.

2. Durability and Workability: The method ensures that concrete mixes are durable enough to resist common pavement issues like cracking from freeze-thaw cycles, while also being workable to allow proper placement and compaction.

3. Consideration of Variables: Factors influencing mix design such as environmental conditions, traffic loading, and the type of pavement (e.g., jointed or continuously reinforced) are taken into account.

The method provides a systematic approach through various calculation steps that guide the selection of parameters essential for achieving desired pavement performance characteristics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of IRC:44 Method

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Tailored for pavement concrete.

Detailed Explanation

The IRC:44 method is specifically designed for concrete used in pavement applications. This method ensures that the pavement concrete meets the required performance criteria, focusing on the unique demands of roads and highways where durability and structural integrity are critical.

Examples & Analogies

Think of the IRC:44 method as a custom recipe for a specific dish that caters to the unique tastes and textures of a cuisine. Just like a recipe is tailored for the best flavor and presentation, this method is adjusted to ensure concrete performs optimally under highway conditions.

Flexural Strength Focus

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Focuses on flexural strength (modulus of rupture) instead of compressive strength.

Detailed Explanation

Unlike many other methods that prioritize compressive strength (the ability of material to withstand axial loads), the IRC:44 method emphasizes flexural strength. Flexural strength refers to the material's ability to withstand bending forces. This is crucial for pavements that experience tensile stresses due to loads from vehicles, ensuring that they do not crack or fail under pressure.

Examples & Analogies

Consider flexural strength like the ability of a gymnast to hold a position on a balance beam. Just as a gymnast needs to maintain balance and flexibility to avoid falling, pavement needs to have sufficient flexural strength to stay intact and serve its purpose without cracking.

Incorporation of Durability and Workability

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Incorporates durability and workability factors.

Detailed Explanation

The IRC:44 method includes considerations for both durability and workability of pavement concrete. Durability ensures that the concrete can resist environmental challenges such as moisture, temperature changes, and chemical attacks, thereby prolonging the pavement's lifespan. Workability is important for ensuring that the concrete can be easily mixed, poured, and placed without compromising structural integrity.

Examples & Analogies

Imagine baking a cake — if the batter (concrete mix) is too thick (poor workability), it won't pour easily into the pan or may not cook evenly. Similarly, if the cake isn't designed well to withstand baking conditions (durability), it might collapse after it cools. Ensuring a proper mix for both workability and durability is crucial for paving success.

Key Concepts

-

Target Mean Flexural Strength: A calculated strength that accounts for variability in materials.

-

Water-Cement Ratio: The ratio of water to cement that influences workability and durability.

-

Trial Mixes: Preliminary mixes used to test and adjust the final concrete formulation.

Examples & Applications

Example of calculating target mean flexural strength using a statistical constant.

Preparation of a trial mix to test the flexural strength and workability before final application.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When flexural strength you need, remember IRC leads.

Stories

Imagine a pavement standing strong against traffic and weather; IRC:44 helps it endure, ensuring it won't tether.

Memory Tools

For IRC:44, remember 'D urable, W orkable, F lexural - the three keys to success!'

Acronyms

IRC

'I mportantly R ely on C oncrete strength'.

Flash Cards

Glossary

- Flexural Strength

The ability of a material to resist deformation under load; essential for pavement durability.

- Modulus of Rupture

A measurement of a material's tensile strength, used in pavement mix design to ensure it can withstand flexural stresses.

- Durability

The ability of a concrete mix to resist wear and degradation under environmental conditions.

- Workability

The ease with which a fresh concrete mix can be placed, shaped, and compacted.

Reference links

Supplementary resources to enhance your learning experience.