Design Procedure (IRC:44-2017 Method)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Target Mean Flexural Strength

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start with the first step in our design procedure, which is to determine the target mean flexural strength. Can anyone tell me why this step is crucial?

I think it’s important because it helps us decide how strong the concrete needs to be.

Exactly! The target mean flexural strength ensures that our design can accommodate the stresses the pavement will face. We use the formula f = f_ck + k × s. Does anyone know what 'k' and 's' stand for?

'k' is the statistical constant, and 's' is the standard deviation, right?

That's correct! We typically use a value of 1.65 for 'k'. This adjustment helps account for variability in materials and workmanship. Why do you think we need this adjustment?

To make sure there's a safety margin, so the concrete performs well even with some variations?

Exactly right! It’s about ensuring reliability in performance. Great job, everyone!

Water-Cement Ratio Selection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Our next step involves selecting the water-cement ratio. Does anyone know how this impacts our concrete mix?

If it's too high, the concrete might be weak, right?

Exactly! A higher water-cement ratio can lead to porous concrete, reducing both strength and durability. We find this ratio through graphs or tables in the IRC/IS standards. What’s an ideal ratio for high-performance pavements?

Usually around 0.35 to 0.40, depending on the desired performance!

Spot on! Now let's think about how we estimate the water content based on this ratio and desired workability. How would we do this?

We need to consider the type of aggregates and the slump requirement!

Correct again! Balancing these factors is key to ensuring our mix has the right properties.

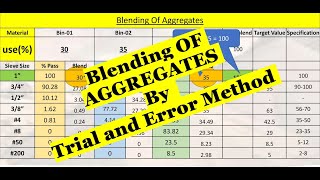

Aggregate Ratio and Grading Selection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s move on to the selection of aggregate ratio and grading. Why do you think this step is important?

It affects the workability and strength of the concrete.

Absolutely! Proper grading ensures a well-graded mix, which enhances both the strength and workability of the concrete. Preferred grading typically involves using Zone II sand. Can anyone tell me why we prefer this?

It's a good balance for strength and workability, making mixing easier.

Great observation! Ensuring the correct proportions of coarse to fine aggregate is essential to achieve that balance. Once we have that, we can proceed to mix calculations. Ready to tackle that?

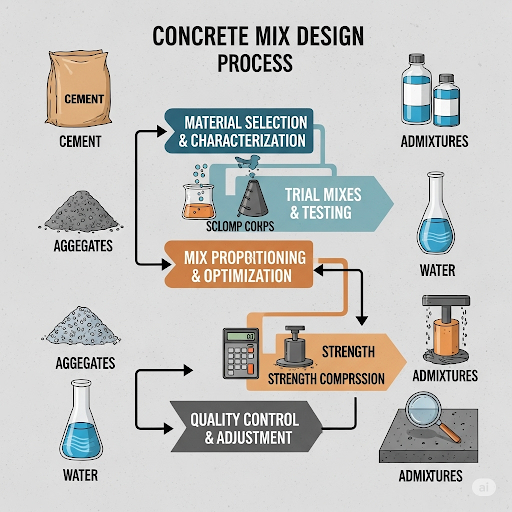

Trial Mixes and Adjustments

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

As we approach the mixing phase, let’s discuss trial mixes and adjustments. Why are trial mixes necessary?

To test our proportions and make sure they work in real conditions?

Exactly! We prepare trial batches to check for flexural strength, workability, air content, and durability indicators. What indicators might we look for?

Things like sulfate resistance and abrasion resistance!

Correct! Once we gather this data, we can make necessary adjustments. Does anyone have thoughts on what adjustments might be needed or how we might apply that data?

We might need to change the water content or adjust the proportions of aggregates.

Exactly! Fine-tuning based on the results of our tests ensures we achieve optimal performance for our pavements. Great job today, everyone!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The design procedure outlined in IRC:44-2017 incorporates crucial steps to achieve the desired flexural strength, water-cement ratio, and aggregate grading for concrete pavements. Each step ensures the concrete mix meets the required performance criteria vital for long-lasting pavement durability.

Detailed

Design Procedure (IRC:44-2017 Method)

The IRC:44-2017 Method is a systematic approach for designing concrete mixes tailored for pavement applications. This method emphasizes the need for determining target mean flexural strength, selecting appropriate water-cement ratios, estimating water content based on desired workability, and ensuring proper grading and proportions of aggregates.

Step-by-Step Breakdown:

- Target Mean Flexural Strength: Calculate the characteristic flexural strength (f_ck) and adjust it using a statistical margin.

- Formula: f = f_ck + k × s, where "k" is typically 1.65.

- Water-Cement Ratio: Choose based on the desired strength and durability.

- Estimation of Water Content: This depends on the required workability.

- Cement Content Calculation: Ensure adequate cement content based on water content and minimum standards.

- Selection of Aggregate Ratios: Choose the correct proportions of coarse and fine aggregates while adhering to grading limits.

- Mix Calculations: Carry out trial mixes to determine ideal condition proportions.

- Trial Mixes and Adjustments: Conduct tests for flexural strength, workability, and durability, making necessary adjustments.

By following these steps, engineers can ensure that pavements are built to last, meeting all required performance criteria.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Step 1: Target Mean Flexural Strength

Chapter 1 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Determine characteristic flexural strength f_ck.

Add margin to account for variation.

f = f_ck + k × s

Where:

- k = statistical constant (usually 1.65)

- s = standard deviation

Detailed Explanation

In this step, the design process begins by identifying the desired flexural strength, which is an indicator of how well the concrete will handle bending forces. The characteristic flexural strength, denoted as f_ck, is based on previous data about similar concrete mixtures. Since there's always some variation in materials and processes, we add a safety margin using a statistical constant (k) and the standard deviation (s) of the flexural strengths from trial batches. Here, k is typically set at 1.65 to ensure that we accommodate variations effectively.

Examples & Analogies

Imagine you're preparing a cake, and you've baked a few batches before. You know your usual recipe yields a tasty cake, but sometimes it turns out slightly better or worse depending on the ingredients' quality or even the oven's temperature. To account for this, you add a little extra sugar (the margin) to ensure the cake is sweet enough even if this time the ingredients aren't perfect.

Step 2: Selection of Water-Cement Ratio

Chapter 2 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Based on target strength and durability.

Check from graphs or tables in IRC/IS standards.

Detailed Explanation

The water-cement (w/c) ratio is crucial because it affects both the strength and durability of the concrete. A lower w/c ratio often leads to stronger concrete but can make it less workable. Therefore, selecting the right w/c ratio involves balancing these factors based on the desired flexural strength and the specific requirements of the pavement. Engineers can refer to standardized graphs or tables to find the appropriate w/c ratio for their needs.

Examples & Analogies

Think about making a smoothie. If you add too much water, your smoothie is runny and not satisfying. If you don’t add enough, it’s too thick to drink. You need to find that perfect balance based on your taste and how thick or thin you want your smoothie.

Step 3: Estimation of Water Content

Chapter 3 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Based on required workability (slump) and aggregate type.

Detailed Explanation

Here, we decide how much water is needed in the mix to achieve the desired workability or consistency, often measured in terms of slump. The type of aggregates also impacts the water requirement; different sizes and shapes of aggregates will influence how much water is necessary to get a workable mix. This step ensures that the concrete can still be easily poured and shaped, but also has the right strength once it hardens.

Examples & Analogies

Imagine trying to pack a suitcase. If you want to fit in more clothes, you might need to roll them tightly to make everything fit. If your suitcase is too full, you might find it difficult to close it. Similarly, you need just the right amount of water to let the aggregates blend without making the mix too runny or too thick.

Step 4: Calculation of Cement Content

Chapter 4 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Cement Content = Water Content / w/c ratio.

Must meet minimum content for durability as per IS 456.

Detailed Explanation

In this step, we calculate the required cement content based on the established water content and the selected w/c ratio. The cement content needs to be sufficient not only to bind the aggregates together but also to ensure durability. The Indian Standard IS 456 specifies minimum cement content requirements to resist environmental factors and ensure sufficient strength in the concrete.

Examples & Analogies

Think of glue used to hold a craft project together. If you don't use enough glue, the pieces may not stick well and could fall apart. However, if you use too much, it becomes messy. The right amount of cement is like the right amount of glue—enough to hold everything firmly together without causing problems later.

Step 5: Selection of Aggregate Ratio and Grading

Chapter 5 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Decide proportion of coarse to fine aggregate.

Confirm compatibility with grading limits (Zone II sand preferred).

Detailed Explanation

Choosing how much coarse aggregate (larger stones) and fine aggregate (sand) to use is critical for ensuring that the concrete can withstand various stresses. The right proportion enhances strength, workability, and reduces potential shrinkage and cracking. Grading refers to the distribution of particle sizes. Zone II sand is often preferred as it strikes a good balance for concrete pavements, ensuring optimal interlocking of particles for strength and stability.

Examples & Analogies

Imagine making a fruit salad. If you put in too many big chunks of fruit (coarse aggregate) and hardly any small pieces (fine aggregate), the salad might be hard to eat. A good mix of various sizes enhances texture and flavor, just like a well-graded mix provides better strength and performance in concrete.

Step 6: Mix Calculations (Trial Mixes)

Chapter 6 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Compute mix proportions by weight.

Make adjustments based on field conditions and test results.

Detailed Explanation

In this step, engineers calculate the precise mix proportions, ensuring they are based on weight for accuracy. These are usually trial mixes meant to test if the proposed mix will perform as expected under actual conditions. Adjustments might be necessary based on results from preliminary tests or specific environmental conditions that could affect the concrete's performance.

Examples & Analogies

Consider an artist mixing paints. They make a few test swatches to see how the colors blend. If the mix doesn’t look right, they adjust the proportions until they achieve the desired shade. Similarly, trial mixes help engineers find the 'right color' of concrete for their project.

Step 7: Trial Mixes and Adjustments

Chapter 7 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Prepare trial batches.

Test for:

- Flexural strength at 28 days.

- Workability (slump).

- Air content.

- Durability indicators (sulfate resistance, abrasion).

Detailed Explanation

This final step involves creating trial batches of the concrete mix to carry out several critical tests. The flexural strength is measured after 28 days to see if it meets the design specifications. Workability indicates how easy the concrete is to manipulate during placement, measured through slump tests. Additionally, checking air content and durability indicators helps determine if the mix will withstand environmental challenges and other stressors over time.

Examples & Analogies

Think of a chef tasting their dish before serving. They may check for flavor, texture, and presentation. Similarly, engineers test the trial mixes to ensure everything is perfect before they commit to large-scale production, just like a chef wouldn't serve a dish without tasting it first.

Key Concepts

-

Target Mean Flexural Strength: Calculate using f = f_ck + k × s, ensuring reliable performance under load.

-

Water-Cement Ratio: Balances desired strength and durability; impacts concrete porosity and overall quality.

-

Aggregate Grading: Proper grading ensures desired strength and workability, typically using Zone II sand.

-

Trial Mixes: Essential for testing proportions and ensuring the final mix meets flexural strength and durability criteria.

Examples & Applications

Example of calculating target flexural strength using the statistical method.

Illustration of choosing the water-cement ratio from IRC/IS standards based on intended performance.

Memory Aids

Interactive tools to help you remember key concepts

Acronyms

F - Flexural strength must be First; W - Water-cement Ratio comes next; A - Aggregates need Attention; T - Test your mixes with Trials.

Rhymes

When designing for pavement with care and might, remember flexural strength is the guiding light.

Memory Tools

To remember the steps: Think 'T-W-E-C-A-T' - Target strength, Water ratio, Estimate water, Cement calculation, Aggregate selection, Trial mixes.

Stories

Imagine an engineer named Flex who determined that strong sidewalks require sturdy mixes. He checks his formula to ensure his concrete can bear the weight of life’s traffic.

Flash Cards

Glossary

- Flexural Strength

The ability of a material to withstand bending forces, measured in MPa.

- WaterCement Ratio

The ratio of the mass of water to the mass of cement in a concrete mix, impacting its strength and durability.

- Gradation

The distribution of particle sizes within a given aggregate.

- Trial Mix

A test batch of concrete prepared to evaluate the performance of the mix proportions.

Reference links

Supplementary resources to enhance your learning experience.