Step 4: Calculation of Cement Content

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Water Content

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we're going to explore how water content is critical for calculating cement in concrete mixes. Can anyone tell me why water content is essential?

Isn’t it because water affects the workability of the concrete?

Exactly! Water content not only aids in workability but directly influences the strength and durability of the cement. We start with determining how much water we need based on target workability. What do we do next?

We use that water content to find out how much cement we need?

Right! We use the formula: Cement Content = Water Content / Water-Cement Ratio. Remember this formula as you calculate.

What happens if we have too little or too much cement?

Good question! Too little cement can lead to weak concrete, while too much can lead to unnecessary costs without significant strength benefits. Balancing it is key for economic design.

In summary, we determine our water content first, then apply it to our cement content calculation using the water-cement ratio.

Water-Cement Ratio Considerations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've discussed water content, let's dive into how we select the water-cement ratio. Why is choosing the right ratio so vital?

I think it determines the strength of the concrete, right?

Precisely! The w/c ratio significantly influences the final compressive and flexural strength of the concrete. A lower ratio typically leads to higher strength but may affect workability.

How do we figure out what the right w/c ratio is?

Great question! We often reference standards like IRC and IS codes which provide guidance based on desired flexural strength and exposure conditions. Remember, choosing the right w/c ratio is a balancing act!

To recap, selecting the proper w/c ratio is crucial for achieving both strength and durability in concrete pavements.

Meeting Durability Standards

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s discuss why there’s a minimum cement content requirement as per IS 456. Why do you think this is important?

To ensure the concrete lasts and performs well under different conditions?

Exactly! The minimum cement content is designed to ensure the mix has enough strength and durability to withstand environmental factors. This way, we avoid issues like cracking or failure.

What would happen if we ignored this guideline?

Ignoring it could lead to weaker concrete that fails prematurely, resulting in costly repairs and maintenance. Always adhere to those standards.

In summary, maintaining the minimum cement content is crucial for the long-term performance of concrete pavements.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The calculation of cement content is crucial for ensuring proper strength and durability of concrete pavements. This involves using the water-to-cement ratio and meeting minimum content standards for durability as specified in IS 456.

Detailed

Calculation of Cement Content

In the design of concrete mixes, particularly for pavements, the calculation of cement content is a key step that influences strength and durability. Based on the established water content and desired water-cement (w/c) ratio, the cement content can be calculated using the formula:

Cement Content = Water Content / Water-Cement Ratio

To ensure that the concrete achieves necessary durability, the minimum cement content must align with guidelines set out in IS 456, which dictates the required amount of cement relative to the other components in the mix. Balancing this content with the other materials—water, aggregates, and admixtures—is essential in ongoing mix design procedures to optimize for both mechanical properties and economic viability.

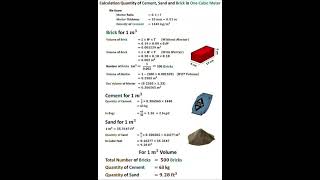

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Water Content Calculation

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Water Content

Cement Content=

w/c ratio

Detailed Explanation

In this step, the amount of cement required for the concrete mix is calculated based on the available water content and the water-cement (w/c) ratio. To find the cement content, we take the total water content and divide it by the w/c ratio, which is a critical value determined in prior steps. The lower the w/c ratio, the stronger the concrete will be, but it must be balanced with workability needs.

Examples & Analogies

Think of baking a cake. If you have a recipe that requires a specific amount of flour (cement) and liquid (water), adjusting the amount of liquid will affect how the cake turns out. Too much water will make the cake soggy (weak), while too little may make it dry (crumbling). Similarly, in concrete, the right ratio of water to cement is essential to achieve the desired strength and durability.

Minimum Cement Content for Durability

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Must meet minimum content for durability as per IS 456.

Detailed Explanation

According to IS 456, a standard code for plain and reinforced concrete, there are minimum cement content requirements that must be met to ensure the concrete can withstand environmental stressors. This minimum content ensures the concrete's durability, preventing issues such as cracking, erosion, and deterioration over time. If the cement content is too low, it may not perform well under the specific conditions for which it was designed.

Examples & Analogies

Consider the foundation of a house. Just as the foundation needs a certain amount of concrete to support the weight of the entire structure effectively, the concrete mix for pavements needs a minimum cement content to ensure it can handle the heavy traffic loads and environmental impacts without failing.

Key Concepts

-

Cement Content: The amount of cement in a concrete mix calculated based on water content and the w/c ratio.

-

Water-Cement Ratio: A critical parameter that influences the concrete's strength and workability.

-

Minimum Cement Content: A guideline to ensure concrete durability against various environmental conditions.

Examples & Applications

If the water content is 200 kg and the desired water-cement ratio is 0.4, the cement content would be calculated as 200 kg / 0.4 = 500 kg.

In a specific project, if the minimum cement content required by IS 456 is 350 kg/m³, designers must ensure that their calculations do not fall below this threshold.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When cement meets water, strength seems to grow, just keep the ratio balanced, and let the quality flow!

Stories

Imagine a builder tasked with constructing a strong road. He wisely calculates his water and cement, ensuring every batch is perfect, allowing vehicles to travel smoothly for years without cracks.

Memory Tools

Remember 'W/C for C!' - Water to Cement for Calculation!

Acronyms

COW - Cement Over Water = Cement calculation.

Flash Cards

Glossary

- Cement Content

The amount of cement required in a concrete mix, usually defined in terms of weight per cubic meter of concrete.

- WaterCement Ratio

The ratio of the mass of water to the mass of cement used in a concrete mix, crucial for determining the strength and durability of the concrete.

- IS 456

A set of Indian standards that provide guidelines for design and construction of reinforced concrete structures, including minimum cement content.

- Durability

The ability of concrete to withstand environmental attacks and mechanical actions over time without significant deterioration.

Reference links

Supplementary resources to enhance your learning experience.