Step 2: Selection of Water-Cement Ratio

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Water-Cement Ratio

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are discussing the water-cement ratio, which is a critical factor in concrete mix design. Can anyone tell me why the water-cement ratio is so important?

It’s important because it affects the strength of the concrete!

Exactly! The water-cement ratio determines the concrete’s compressive strength and its overall durability. Can anyone think of what happens if there’s too much water?

I think it can weaken the concrete and lead to more cracking.

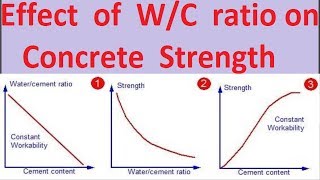

Correct! A high w/c ratio can compromise strength while improving workability. So, the right balance is key. Remember: lower w/c leads to higher strength but lower workability.

Factors Influencing the Selection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about the factors that influence our choice of water-cement ratio. What do you think we should consider?

I think environmental conditions like temperature and moisture levels could affect it.

Exactly right! Environmental conditions indeed affect concrete performance. Besides that, we also need to consider the intended strength of the concrete and the workability required. Who can remember where we find guidance on selecting the w/c ratio?

We can use graphs or tables from IRC and IS standards!

Great recall! These standards help us formulate an effective concrete mix that meets all necessary criteria. Always refer to them when determining your w/c ratio.

Practical Application of Water-Cement Ratio

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s put our understanding into practice. Imagine you are designing a mix for a new highway pavement. Given that you need a target strength of 30 MPa, how would you approach the selection of your water-cement ratio?

I would first check the IRC tables to find the corresponding w/c ratio for that strength.

Precisely! After retrieving that information, what else should you take into account?

I would also consider the environmental factors that might influence the concrete once it sets.

Spot on! Balancing the strength with workability and environmental influences is essential for effective pavement design.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

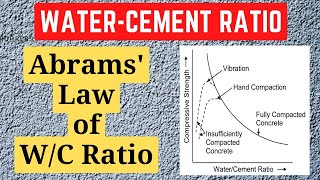

Selecting the water-cement ratio is crucial in achieving the target strength and enhancing durability in concrete pavements. This step is informed by graphs or tables provided in IRC/IS standards, emphasizing the balance between these two factors.

Detailed

Selection of Water-Cement Ratio

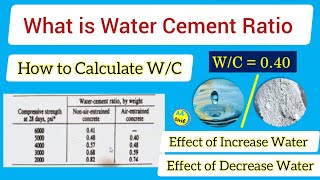

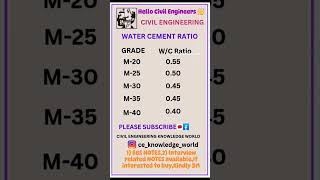

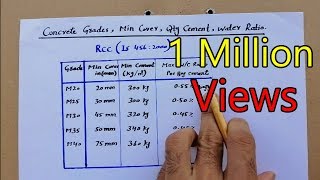

In the design of concrete mixes for pavements, Step 2 involves selecting an appropriate water-cement (w/c) ratio. This ratio is pivotal as it directly influences the concrete’s compressive strength and durability. A lower w/c ratio typically yields higher strength, but can affect workability, while a higher ratio enhances workability but may compromise strength. Engineers rely on established graphs or tables from IRC/IS (Indian Roads Congress / Indian Standards) standards to determine the appropriate w/c ratio based on their target strength requirements and expected environmental conditions. This procedure necessitates careful consideration of the specific pavement characteristics required for longevity and performance.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Water-Cement Ratio

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Based on target strength and durability.

Detailed Explanation

The water-cement ratio is crucial in determining the strength and durability of concrete. It is the ratio of the weight of water to the weight of cement used in a concrete mix. A lower ratio typically leads to stronger concrete, but if it's too low, the concrete may become unworkable. Therefore, it must be balanced carefully based on the desired target strength and the environmental conditions the concrete will face.

Examples & Analogies

Think of baking a cake. If you use too much water, your cake will be soggy and weak, but if you use too little, it may turn out dry and crumbly. Similarly, in concrete, the water-cement ratio has to be just right to ensure that the 'cake' of concrete is strong and durable, allowing it to withstand heavy loads and weather conditions.

Checking the Water-Cement Ratio

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Check from graphs or tables in IRC/IS standards.

Detailed Explanation

To properly select the water-cement ratio, engineers refer to established standards, such as those provided by the IRC (Indian Roads Congress) or IS (Indian Standards). These documents contain graphs and tables that correlate various mixes' water-cement ratios with their expected strengths. By locating the target strength on these tables, an appropriate water-cement ratio can be identified that should meet the necessary requirements for strength and durability.

Examples & Analogies

Imagine trying to find the perfect recipe for your favorite dish. You would likely consult a cookbook that provides various recipes with specific ingredient ratios. Similarly, engineers use these standards as a cookbook to determine the right amount of water needed for achieving the concrete's desired properties.

Key Concepts

-

Water-Cement Ratio: Essential for determining concrete strength and durability.

-

IRC Standards: Provide crucial guidelines for selecting appropriate water-cement ratios.

Examples & Applications

A target flexural strength of 4.5 MPa may correspond to a water-cement ratio of about 0.38 as per IRC/IS standards.

In hot climates, a higher water-cement ratio may be required for better workability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Water low, strength will grow; Water high, strength may die!

Stories

Once a builder learned that mixing too much water in concrete led to weak roads, he began consulting the IRC standards to find the perfect w/c ratio, transforming his projects.

Memory Tools

WCS - Water-Cement Strength; remember, mix it right for structure tight!

Acronyms

WCS

Water-Cement Strength is vital for concrete health!

Flash Cards

Glossary

- WaterCement Ratio

The ratio of the weight of water to the weight of cement used in a concrete mix, influencing its strength and durability.

- IRC Standards

Guidelines provided by the Indian Roads Congress that detail the design specifications for concrete mixes, including water-cement ratios.

Reference links

Supplementary resources to enhance your learning experience.