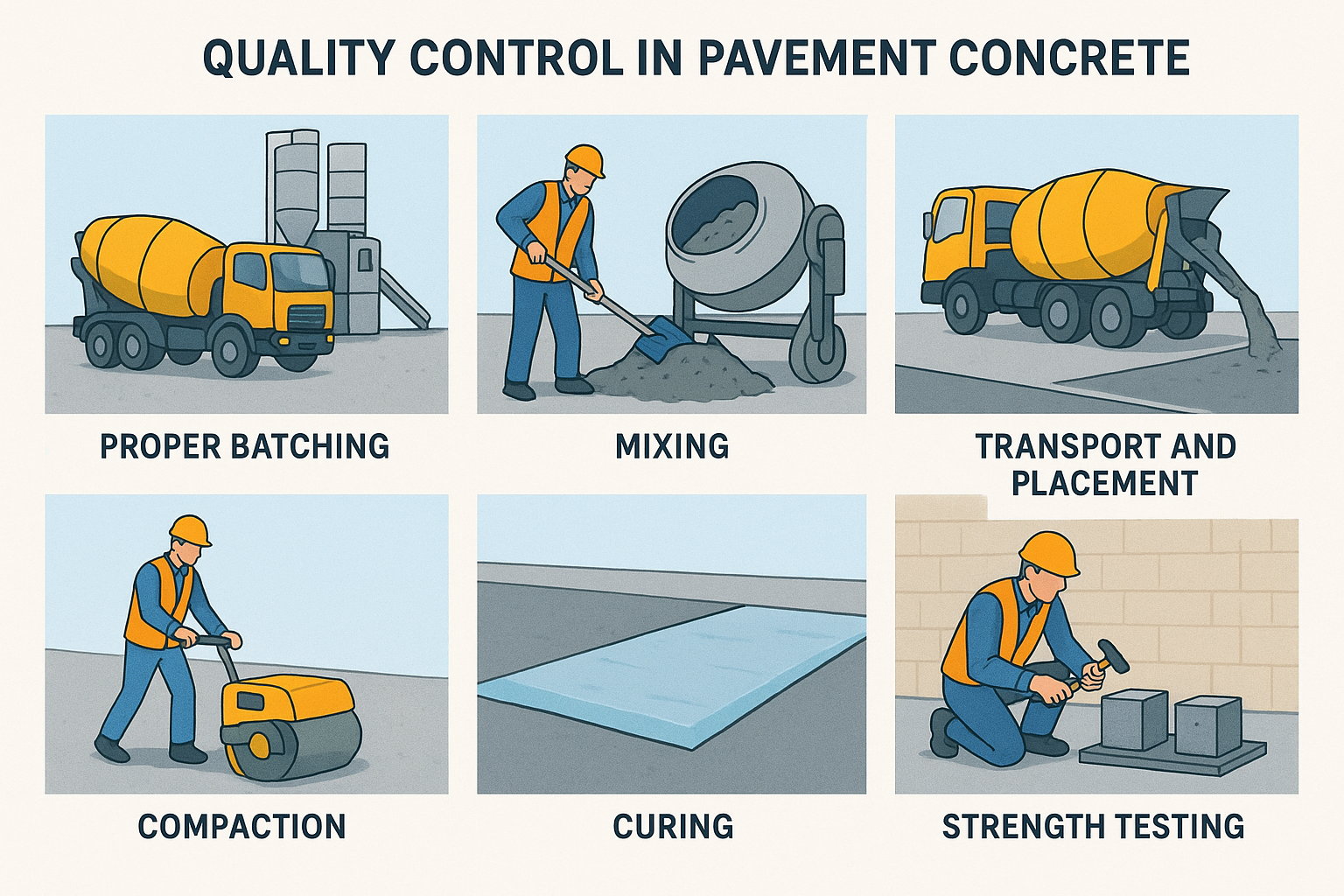

Quality Control in Pavement Concrete

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Batching Accuracy

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll start with batching accuracy, which is crucial for quality control in pavement concrete. Can anyone explain what batching accuracy means?

It means measuring all ingredients correctly before mixing them.

Exactly! It's vital to use weigh-batchers or batching plants to ensure we get the right proportions. Does anyone know why the accuracy of batching is so significant?

It affects the overall strength and durability of the concrete, right?

Correct! Remember, too much water can weaken the mix. A good way to remember this is the acronym 'BAM': Batching, Accurate, Materials. Let's move to mixing.

Mixing Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss mixing. What do you think is important when mixing concrete?

We need to mix it for enough time to get it uniform.

Precisely! Using pan mixers or transit mixers with adequate time helps achieve a homogenous mix. What happens if the mix isn't uniform?

It could lead to weak spots in the pavement.

Right again! Remember the phrase 'Mix it to fix it' as a mnemonic to always ensure uniformity. Let’s move on to transporting and placing.

Transporting and Placing Concrete

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Transporting concrete properly is also crucial. Why do you think we should avoid delays and segregation during this stage?

Delays can make the concrete set before it's laid, right?

Exactly! Delays can lead to weaker structures. Can someone explain what segregation means?

It's when the larger aggregates separate from the mix.

Right! Using the phrase 'Solid Transport, Strong Concrete' can help remember this principle. Next, let’s discuss compaction.

Compaction Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Compaction reduces the air voids, which is critical for concrete strength. What tools do we use?

We can use vibrators or slip-form pavers.

That’s correct! Good compaction leads to better strength and durability. Who can tell me a simple way to remember the compaction importance?

Compacted Concrete is Happy Concrete!

Great! Let's wrap up with curing techniques.

Curing Methods in Quality Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Curing is often overlooked but is vital. What’s the ideal duration for curing concrete?

At least 14 days, if I'm correct?

Absolutely! Continuous wet curing prevents moisture loss. Who remembers why this is important?

It helps achieve the required strength and prevents cracking.

Perfect! Use the saying 'Cure for’sure for strength’ to remember curing's significance. Let's recap what we've discussed today.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In quality control for pavement concrete, accuracy in batching and mixing, careful transportation and placement, effective compaction, and proper curing methods are essential. Regular strength monitoring and adherence to quality standards are also crucial for the long-term performance of concrete pavements.

Detailed

Quality control in pavement concrete is vital to ensure that the concrete meets structural and durability requirements. Proper batching ensures the correct proportions of materials; employing weigh-batchers or batching plants can enhance accuracy. Mixing with adequate time and suitable equipment, such as pan or transit mixers, ensures homogeneity of the mix. Careful transport and placement minimize segregation and delays, crucial for achieving desired concrete characteristics. Compaction, often achieved using vibrators or slip-form pavers, reduces air voids, thus enhancing strength. Continuous curing for at least 14 days is critical to prevent moisture loss, contributing to adequate strength development. Lastly, regular strength monitoring through cube or beam tests allows for adjustments and confirmation that the concrete meets specified standards, ultimately ensuring a durable and reliable pavement structure.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Batching Accuracy

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Batching Accuracy: Use weigh-batchers or batching plants.

Detailed Explanation

Batching accuracy is essential in concrete mix design. It refers to the precise measurement of ingredients (like cement, aggregates, water, and admixtures) before the mixing process. Using weigh-batchers or batching plants helps ensure that each material is added in the correct proportions, which can impact the overall quality and consistency of the concrete. Accurate batching is crucial because even small deviations can lead to significant performance issues in the pavement concrete.

Examples & Analogies

Imagine cooking a recipe that requires precise measurements, like making a cake. If you add too much flour or not enough sugar, the cake won't rise properly or may taste off. Similarly, in concrete, precise batching ensures that the final product meets the desired strength and durability.

Mixing Process

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Mixing: Pan mixers or transit mixers with adequate mixing time.

Detailed Explanation

The mixing phase is when all the ingredients come together to form concrete. Using pan mixers or transit mixers is recommended because they provide thorough mixing of materials. Adequate mixing time is crucial to ensure that all components are evenly distributed. Inadequate mixing can result in weak spots in the concrete, leading to potential failures in the pavement.

Examples & Analogies

Think about blending a smoothie. If you don’t mix it long enough, you’ll end up with clumps of fruit instead of a smooth drink. Proper mixing for concrete ensures that every scoop has the same quality and strength, just like a smoothie should be uniform throughout.

Transporting and Placing

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Transporting and Placing: Avoid segregation and delays.

Detailed Explanation

Once the concrete is mixed, it must be transported to the job site quickly and placed efficiently. Segregation occurs when the larger aggregates in the mix separate from the finer materials, which can happen during transport. This can lead to inconsistencies in the concrete composition. It's important to minimize delays during this process to maintain the concrete’s workability before it begins to set.

Examples & Analogies

Imagine pouring a bag of mixed nuts. If you shake the bag, the larger nuts will rise to the top while the smaller ones sink to the bottom—this is segregation. We want to keep our mixture uniform, just like when we want a mix of all the nuts in every handful!

Compaction Method

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Compaction: Use vibrators or slip-form pavers.

Detailed Explanation

Compaction is the process of increasing the density of the concrete. It helps to remove air bubbles and ensures the concrete tightly flows around the aggregates. Using vibrators or slip-form pavers helps achieve proper compaction, thereby increasing strength and durability while reducing the risk of voids in the pavement.

Examples & Analogies

Consider packing a suitcase. If you gently place your clothes, you won’t fit much in there, but if you press them down and organize efficiently, you can fit more items. Similarly, compaction helps fit the concrete material together tightly, creating a stronger surface.

Curing Process

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Curing: Continuous wet curing for 14 days or equivalent.

Detailed Explanation

Curing is vital for the hydration of concrete, which is the chemical process that helps it gain strength. Continuous wet curing for at least 14 days ensures that the concrete remains moist, allowing it to achieve its full strength and durability. This is important, especially in hot and windy conditions where moisture can evaporate quickly.

Examples & Analogies

Think of maintaining a plant's health. Just like plants need regular watering to grow strong and healthy, concrete requires consistent moisture during the curing phase to reach its optimal strength.

Strength Monitoring

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Strength Monitoring: Regular cube or beam testing.

Detailed Explanation

To ensure the quality of pavement concrete, strength monitoring is conducted through regular testing of concrete cubes or beams. These tests assess whether the concrete has achieved the desired strength after curing. Testing helps identify any issues early on, allowing for adjustments in the mix or structural design if necessary.

Examples & Analogies

It's similar to getting regular health check-ups to monitor your well-being. Just as doctors perform tests to check your health, regular testing of concrete checks its strength and ensures it's safe and durable for pavement use.

Key Concepts

-

Batching Accuracy: Ensures precise proportions of materials, vital for concrete quality.

-

Mixing: Key for achieving a uniform concrete mix.

-

Transporting: Careful movement of concrete prevents segregation.

-

Compaction: Reduces air voids, enhancing strength.

-

Curing: Sustains moisture for adequate concrete strength development.

Examples & Applications

Using weigh-batchers to ensure exact material proportions.

Employing vibrators during placement for effective compaction.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Batch with care, mix and share, transport fast, ensure it lasts!

Acronyms

BMT CC

Batching

Mixing

Transporting

Compaction

Curing.

Stories

Once, there was a concrete road that faced many challenges because it was poorly mixed and not cured; it cracked and crumbled, teaching everyone the importance of quality control.

Memory Tools

Remember 'A Smooth Path Needs BMT CC' for the steps of quality control.

Flash Cards

Glossary

- Batching Accuracy

The precision in measuring and combining raw materials in concrete mix design.

- Mixing

The process of combining concrete ingredients to create a homogeneous mixture.

- Transporting

The act of moving concrete from the mixing site to the placement site without segregation.

- Compaction

The process of densifying concrete by removing air voids through vibrators or other means.

- Curing

The process of maintaining adequate moisture, temperature, and time to allow the concrete to gain strength.

Reference links

Supplementary resources to enhance your learning experience.