Constituents of Concrete for Pavements

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Cement is a crucial binding agent in concrete. Can anyone tell me which types of cement are commonly used for pavements?

Isn't Ordinary Portland Cement one of them?

Absolutely! We often use OPC in grades 43 or 53. Additionally, blended cements like PPC and PSC can also be used. Why do you think the choice of cement matters?

It must affect the strength and durability of the concrete?

Exactly! Factors such as consistency and setting time are vital, particularly for pavements undergoing heavy traffic. Remember: A = Cement's Role, B = Binding Strength. Keep that acronym in mind!

What properties should we check for when choosing cement?

Great question! We look for its consistency, setting time, fineness, and strength development. Let's summarize: Cement is the glue that holds concrete together and significantly impacts its performance!

Role of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s dive into aggregates. Can someone explain the difference between coarse and fine aggregates?

Coarse aggregates are larger stones, while fine aggregates are more like sand, right?

Exactly! Coarse aggregates should be angular and clean, and fine aggregates must conform to specific grading limits. Why do you think grading is essential in concrete mix?

It must help in achieving the right strength and workability?

You're spot on! Proper grading leads to a well-balanced mix. Remember: G = Grading for strength, W = Workability! Keep this in mind throughout your studies.

Water Quality in Concrete

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about water in the mix. Why do we emphasize using potable water for concrete?

It’s likely to prevent contaminants from affecting the strength!

Correct! The pH should be between 6 and 8. Anything outside this range or harmful impurities can lead to durability issues. Quick memory aid: P = Potable Water, S = Safe Strength!

Using Admixtures Effectively

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's cover admixtures. Can you name some different types of admixtures used in pavement construction?

I know we have plasticizers and air-entraining agents.

Correct! Plasticizers enhance workability, while air-entraining agents add freeze-thaw resistance. Why might we need retarders or accelerators?

Maybe to adjust the set time based on the weather?

Absolutely right! Remember: A = Adapt with Weather, S = Set Time! This thinking will aid you during practical applications!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Concrete pavements require specific constituent materials to ensure strength, durability, and workability. This section outlines the types and properties of cement, aggregates, water quality, and various admixtures that can enhance concrete performance in pavement applications.

Detailed

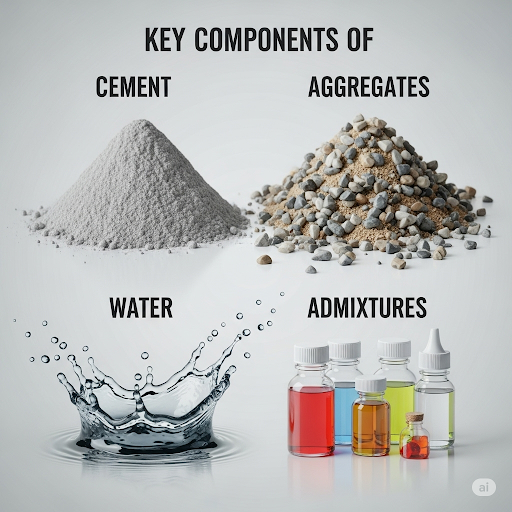

Constituents of Concrete for Pavements

Concrete pavements are a fundamental component of modern roadways, providing longevity and resilience. The mix design for concrete pavements is influenced by the selection and quality of its constituents. This section dives into the primary materials used in concrete for pavement construction:

17.3.1 Cement

Cement is the binding agent in concrete. Common types include:

- Ordinary Portland Cement (OPC): Used frequently in grades 43 or 53.

- Blended Cements: Such as PPC (Portland Pozzolana Cement) and PSC (Portland Slag Cement), which enhance specific properties.

The essential properties to consider include consistency, setting time, fineness, and strength development.

17.3.2 Aggregates

Aggregates significantly affect concrete's performance. They are divided into:

- Coarse Aggregates: These should be angular, hard, and free from impurities, typically crushed stone.

- Fine Aggregates: Must be clean river sand or manufactured sand adhering to prescribed grading limits to ensure a balanced mix for strength and workability.

Proper grading is critical to achieving desired concrete properties.

17.3.3 Water

Water quality is crucial for concrete mix performance.

- Potable Water: Should have a pH between 6 and 8 and be free from harmful chlorides and sulfates that could affect the concrete's durability and performance.

17.3.4 Admixtures

Admixtures modify concrete properties, with several types available:

- Water-reducing agents (Plasticizers): To enhance workability without increasing water used.

- Superplasticizers: Used for achieving high-strength concrete or a lower water-cement ratio.

- Air-entraining agents: Help resistance against freeze-thaw cycles.

- Retarders or accelerators: Selected based on environmental conditions to alter setting rates.

The careful selection and proportioning of these constituents dictate the successful application of concrete for pavement design, allowing it to meet the necessary performance criteria while being cost-effective.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Cement Types and Properties

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

17.3.1 Cement

- Type: Ordinary Portland Cement (OPC) – 43 or 53 grade, or blended cement like PPC or PSC.

- Properties: Consistency, setting time, fineness, strength development.

Detailed Explanation

This chunk focuses on the types of cement used in concrete for pavements and their key properties. The most common type is Ordinary Portland Cement (OPC), which comes in different grades like 43 or 53. These grades indicate the compressive strength of the cement. Additionally, blended cements such as PPC (Portland Pozzolana Cement) or PSC (Portland Slag Cement) may also be used. The properties mentioned, like consistency, setting time, fineness, and strength development, are essential for ensuring that the cement performs well in concrete mixes, affecting the final strength and durability of pavement.

Examples & Analogies

Think of cement as the glue in a recipe. Just like using the right kind of glue is crucial for keeping your ingredients together in a baking recipe, using the correct type of cement is vital for binding the materials in the concrete mix effectively. If you choose a cement that doesn't fit the recipe (or application), the final product might crumble or not set properly.

Aggregate Types and Grading

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

17.3.2 Aggregates

- Coarse Aggregates: Angular, hard, and clean crushed stone.

- Fine Aggregates: Clean river sand or manufactured sand conforming to grading limits.

- Grading: Must ensure a well-graded mix for strength and workability.

Detailed Explanation

In this section, we focus on the types of aggregates used in concrete for pavements. Coarse aggregates are usually angular in shape, hard, and clean, consisting of crushed stone. They help in providing strength and stability to the concrete. Fine aggregates, on the other hand, can be clean river sand or manufactured sand, and they fill the gaps between coarse aggregates. Well-graded aggregates are crucial because they contribute to the overall strength and workability of the concrete mix, ensuring that the concrete is neither too dense nor too loose.

Examples & Analogies

Consider aggregates as the building blocks of a sandcastle. If you use large, uneven rocks, the castle might fall apart easily (like using poor quality coarse aggregates). On the other hand, fine sand fills the gaps between these larger rocks, helping to bind them together. Just as a well-made sandcastle has the right combination of sand and larger pieces, a good concrete mix requires the proper balance of coarse and fine aggregates.

Water Quality Requirements

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

17.3.3 Water

- Potable water with pH between 6 and 8.

- Free from chlorides and sulfates.

Detailed Explanation

Water plays a vital role in the concrete mix, as it is necessary for the hydration of the cement. The quality of water used is important: it should be potable (safe for drinking) and have a pH level between 6 and 8. Additionally, the water should not contain chlorides and sulfates, as these can adversely affect the strength and durability of the concrete. Using the right type of water ensures that the chemical reactions during cement hydration proceed optimally.

Examples & Analogies

Imagine mixing a cake batter. If you use clean, fresh water, the cake will rise properly, but if you use salty or contaminated water, it could ruin the flavor and texture. In the same way, using clean, appropriate water in concrete mixes ensures the 'cake' (concrete) develops its best properties.

Admixtures and Their Functions

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

17.3.4 Admixtures

- Water-reducing agents (Plasticizers).

- Superplasticizers for high strength or low w/c ratio.

- Air-entraining agents for freeze-thaw resistance.

- Retarders or accelerators depending on climatic conditions.

Detailed Explanation

Admixtures are materials added to the concrete mix to modify its properties and improve performance. Water-reducing agents, also known as plasticizers, help reduce the water content while maintaining workability. Superplasticizers allow for achieving higher strength with a lower water-to-cement (w/c) ratio, which is beneficial for durability. Air-entraining agents help create tiny air bubbles in the mix, enhancing freeze-thaw resistance. Additionally, retarders slow the setting time, while accelerators speed it up, both of which can be crucial in different weather conditions. The careful selection of admixtures can greatly enhance the performance and longevity of the concrete.

Examples & Analogies

Think of admixtures like spices in cooking; just as different spices can change the flavor and texture of your dish, different admixtures can modify the properties of concrete. For instance, a superplasticizer is like adding a hint of sugar in a recipe; it allows for a smoother mix (like a smoother batter) while enhancing the final results (stronger concrete)!

Key Concepts

-

Cement: The primary binding agent in concrete responsible for strength.

-

Aggregates: Materials providing structure and strength to the concrete mix.

-

Water: Essential for hydration of cement and determining workability.

-

Admixtures: Enhance or modify certain properties of concrete.

Examples & Applications

Using Ordinary Portland Cement for a highway pavement mix for durability.

Incorporating air-entraining agents to ensure freeze-thaw resistance in cold climates.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For strong concrete, a mix you must aim, / Cement and aggregates play the main game.

Stories

Imagine building a road. You use special cement to bind rocks together. If you pick the wrong kind, your pavement crumbles!

Memory Tools

CWA - Cement, Water, Aggregates: Remember these for concrete!

Acronyms

C3A - Cement, Clean Aggregates, Correct water

Key components for a solid mix.

Flash Cards

Glossary

- Cement

A binding agent used in concrete, commonly Ordinary Portland Cement or blended varieties.

- Aggregates

Materials such as sand or gravel used in concrete to provide strength and stability.

- Admixtures

Chemical substances added to concrete to modify its properties.

- Potable Water

Drinking water that is safe for use in concrete mixes.

Reference links

Supplementary resources to enhance your learning experience.