Use of Supplementary Cementitious Materials

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to SCMs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore Supplementary Cementitious Materials, or SCMs. Can anyone tell me why we might want to use materials like fly ash or silica fume in concrete?

Maybe because they can make the concrete stronger?

Great point! SCMs can indeed increase the strength of concrete. Additionally, they help improve durability, which is crucial for pavement applications.

What exactly do they provide in terms of durability?

SCMs can reduce permeability and enhance resistance to environmental factors. Think about it as adding a protective layer to your concrete mix!

So, it makes the concrete last longer?

Exactly! They can prolong service life by mitigating effects from factors like freeze-thaw cycles and chemical attacks. Always remember the acronym DSS: Durability, Strength, Sustainability.

DSS! Got it!

Fantastic! To wrap up, SCMs not only enhance concrete but also make it more environmentally sustainable by reducing the need for Portland cement.

Types of SCMs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss types of SCMs. Who can name one type?

Fly ash?

Correct! Fly ash is one type, derived from burning pulverized coal. Does anyone know about its benefits?

It can improve workability and reduce segregation?

Exactly! Fly ash plays a significant role in enhancing workability while also lowering the heat of hydration. Let's not forget about GGBS. Student_3, what do you think GGBS contributes?

I heard it enhances resistance to chemical attacks.

Spot on! GGBS improves resistance primarily in sulfate-rich environments. And silica fume?

I think it helps with high strength?

Exactly! Silica fume offers high-performance advantages, especially in dense concrete applications. Remember, the proper application of these materials is key to concrete durability.

Environmental Benefits of SCMs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's shift the focus to the environmental implications. Why do you think using SCMs can be seen as an eco-friendly approach?

Because it reduces the amount of Portland cement we use, right?

Exactly! Reducing cement use decreases CO2 emissions significantly. How much do you think we could lower emissions by substituting SCMs?

By a lot? Cement production is really emissions-heavy.

You are correct! Studies suggest we could reduce emissions by at least 20-30% depending on the use of SCMs. Additionally, utilizing by-products like fly ash promotes recycling. That's a win-win!

So using these materials helps the planet!

Yes! Sustainability in concrete not only helps with durability but also supports environmental stewardship.

I'll remember that — eco-friendly concrete!

Excellent! Let's summarize: SCMs improve durability, strength, and are crucial for environmental sustainability.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the significance of using Supplementary Cementitious Materials in concrete pavements, highlighting their role in improving durability and promoting sustainability in concrete mix design.

Detailed

Use of Supplementary Cementitious Materials

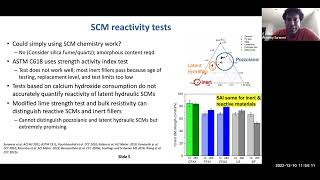

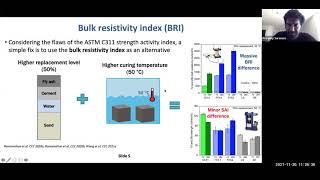

Supplementary Cementitious Materials (SCMs), such as fly ash, Ground Granulated Blast-Furnace Slag (GGBS), and silica fume, are increasingly recognized for their benefits in concrete pavements. These materials can improve the properties of concrete, contributing to enhanced durability and sustainability. The incorporation of SCMs can lead to reduced permeability, improved strength over time, and increased resistance to various environmental stresses.

Utilizing these materials not only lessens the environmental impact of concrete production by reducing the need for Portland cement but also promotes a shift towards greener building practices. Their ability to substitute traditional cement components can significantly contribute to the overall performance and longevity of concrete pavements, making them a desirable choice in modern engineering practices.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Supplementary Cementitious Materials (SCMs)

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Supplementary Cementitious Materials include fly ash, GGBS, and silica fume, which are used to improve the durability and sustainability of concrete pavements.

Detailed Explanation

SCMs are materials that can replace a part of Portland cement in concrete. They enhance the properties of concrete by contributing to its strength and durability while being more environmentally friendly. Fly ash is a byproduct from coal combustion, GGBS is produced from the slag of iron, and silica fume is a byproduct of silicon production. Using these materials helps reduce carbon emissions associated with traditional cement production.

Examples & Analogies

Think of SCMs like adding nutritional supplements to a diet. Just like how vitamins and minerals can enhance our health, SCMs boost the properties of concrete, making it stronger and more resilient, while also benefiting the environment.

Benefits of Using SCMs

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The incorporation of SCMs in concrete mix design provides numerous advantages, including improved durability, decreased permeability, and enhanced resistance to environmental factors.

Detailed Explanation

When SCMs are added to concrete, they can significantly improve the longevity of pavements. The chemical reactions between SCMs and the components of concrete lead to a denser and less porous structure, which helps in resisting water penetration and the harmful effects of chemicals, such as sulfates. This ultimately extends the lifespan of the pavement and reduces maintenance costs.

Examples & Analogies

Consider how adding more protective layers to a jacket makes it suitable for harsh weather conditions. Similarly, adding SCMs makes concrete more robust against environmental factors, ensuring it withstands rain, snow, and other challenges over time.

Sustainability Considerations

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Using SCMs also supports sustainable construction practices by reducing the carbon footprint associated with concrete production.

Detailed Explanation

The traditional production of Portland cement is energy-intensive and generates a significant amount of CO2. By using SCMs, which are often waste materials or byproducts, we can reduce the amount of cement needed for a concrete mix. This not only consumes fewer resources but also diminishes greenhouse gas emissions from cement manufacturing, promoting a more sustainable approach to construction.

Examples & Analogies

It's like recycling paper instead of cutting down more trees to make new paper. By reusing materials that otherwise would be waste, we conserve resources and reduce our impact on the environment.

Key Concepts

-

Supplementary Cementitious Materials (SCMs): Enhance concrete's strength and durability while reducing environmental impact.

-

Fly Ash: A common SCM that improves workability and strength.

-

GGBS: Improves chemical resistance and overall durability of concrete mixes.

-

Silica Fume: Provides high-performance qualities in concrete, particularly with high-strength applications.

Examples & Applications

Using 30% fly ash in a concrete mix can lead to increased long-term strength and reduced permeability.

Incorporating GGBS instead of Portland cement in marine structures improves resistance to sulfate attacks.

Silica fume used in high-performance concrete leads to reduced porosity and enhanced compressive strength.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

SCMs in mix, strong and sustainable, with durability fixed!

Stories

Imagine a construction worker using magic dust — fly ash, GGBS, and silica fume. This dust makes concrete stronger, more durable, and saves the planet.

Memory Tools

Remember 'FGS' for Fly, GGBS, and Silica - the trio of SCMs!

Acronyms

Use 'DSS' — Durability, Strength, Sustainability to remember benefits.

Flash Cards

Glossary

- Supplementary Cementitious Materials (SCMs)

Materials used in concrete that supplement the main cement, improving strength, durability, and sustainability.

- Fly Ash

A by-product from burning pulverized coal, used to enhance concrete performance.

- GGBS

Ground Granulated Blast-Furnace Slag, a by-product from steel manufacturing that improves durability when added to concrete.

- Silica Fume

A by-product of silicon metal production, providing high strength and reduced porosity in concrete.

Reference links

Supplementary resources to enhance your learning experience.