Adulteration and Shelf Life of Cement

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

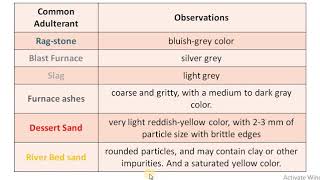

Adulteration of Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about the impact of adulteration on cement. Can anyone tell me what adulteration means in this context?

Does it mean mixing cement with other materials?

Exactly! Adulteration refers to adding excessive fly ash or sand to cement. When we mix too much of these materials, what happens to the strength of cement?

It weakens it, right?

Correct! A good mnemonic to remember is 'A Fat Cement is Weak!' which emphasizes that a cement mix high in adulterants is inferior. What might be some observable signs of adulterated cement?

Maybe changes in color or texture?

That’s right! Lumpy bags or poor flowability are clear indicators. Always check for these signs before using cement.

So, we need to be cautious about the quality before starting a project?

Absolutely. Quality checks are crucial. Let’s summarize: adulteration affects both strength and usability of cement, and any visible signs should alert us to potential issues.

Shelf Life of Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss shelf life. What do we mean by the shelf life of cement?

Is it how long cement can be stored before it goes bad?

Exactly! The ideal shelf life of cement is three months. If it exceeds this time, what can happen?

It might lose its strength or get hard?

Correct! Exposure to moisture is a major factor in this deterioration. Can anyone think of ways to store cement to prolong its shelf life?

Keeping it in a dry place, maybe in sealed bags?

Yes, air-tight, moisture-free storage is crucial. Remember, following the FIFO method—First In, First Out—is important for managing stored cement. To conclude, what are key takeaways on the shelf life of cement?

Check the date, store properly, and watch for moisture.

Well summarized! Always prioritize quality to ensure successful construction practice.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Cement can lose its strength due to adulteration with excessive fly ash or sand and can also absorb moisture from the atmosphere. Proper storage is crucial, as the shelf life of cement is ideally three months, and certain visible signs can indicate deterioration.

Detailed

Adulteration and Shelf Life of Cement

Cement is crucial for construction, but its quality can be compromised through adulteration or improper storage. Adulteration, which entails mixing cement with excessive amounts of fly ash or sand, can significantly weaken its properties, leading to inferior concrete performance. Additionally, exposure to atmospheric moisture results in the hardening or lumping of cement, making it unusable. The ideal shelf life of cement is around three months. Exceeding this shelf life increases the likelihood of deterioration, impacting strength and workability. Field checks for signs such as lumpy bags or poor flowability can help in identifying degraded cement, ensuring that only quality materials are used in construction.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Causes of Cement Strength Loss

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Cement may lose strength if:

- It is adulterated with excessive fly ash or sand.

- It absorbs atmospheric moisture.

- It is used beyond its shelf life (3 months ideally).

Detailed Explanation

Cement can lose its effectiveness and strength due to three primary factors. First, if too much fly ash or sand is mixed with the cement, it can dilute the binding properties necessary for strong concrete. This is termed 'adulteration.' Second, cement is highly sensitive to moisture; if it absorbs water from the atmosphere, it can clump or harden improperly, which reduces its usability. Lastly, all cement has a shelf life, typically around three months. Beyond this time, the chemical compounds in the cement can start reacting with moisture or other elements, leading to a decline in performance.

Examples & Analogies

Think of cement like a loaf of bread. If you add too much flour (like fly ash or sand) to the dough, you lose the recipe's intended taste. Similarly, if you leave the bread in a humid environment, it can go stale or moldy. Just like bread, cement has an expiration date; if you don’t use it within a few months, it may not rise properly in your construction, which means it won't hold up well under weight or pressure.

Detecting Deteriorated Cement

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Field checks for lumpy bags, poor flowability, or color changes can help detect deteriorated cement.

Detailed Explanation

To ensure the quality of cement before use, various field checks can be performed. One method is to look for lumpy bags, which indicates clumping likely caused by moisture absorption. Additionally, checking the flowability is important; if cement does not flow freely when poured, it suggests it may have absorbed moisture or deteriorated. Finally, any noticeable color changes can signal that the cement's chemical composition has altered unfavorably. All these checks help determine if the cement is still usable.

Examples & Analogies

Imagine checking the freshness of a box of cereal. If the cereal is clumpy, doesn’t pour easily, or the color seems off—perhaps it looks darker or more faded than usual—you might decide not to eat it. Cement requires similar checks; maintaining its quality is essential for ensuring strong and durable concrete structures.

Key Concepts

-

Adulteration: The quality of cement can be negatively impacted if it contains excessive fly ash or sand.

-

Shelf Life: Cement should ideally be used within three months of production to ensure maximum strength.

-

Moisture Effects: Moisture can cause cement to form lumps and reduce its effectiveness.

-

Quality Checks: Observing indicators of deteriorated cement, such as lumpy or poor-flowing bags, is crucial before use.

Examples & Applications

Adulterated cement might contain a mix of 30% fly ash, which reduces the overall strength of the concrete made from it.

If a bag of cement has been stored for four months in a humid environment, it may show signs of lumps and hardening.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cement in a moist bin, strength will wear thin.

Stories

Imagine a builder who always kept cement in a warm, dry place. Then one day, he left a bag outside, and it hardened. He learned to respect the three-month rule.

Memory Tools

M-A-S: Moisture Absorption Slumps cement quality.

Acronyms

SHELF

'Store

Hold

Expect Low Flow' – for cement storage.

Flash Cards

Glossary

- Adulteration

The process of adding inferior materials to cement, which reduces its quality.

- Shelf Life

The length of time cement can be stored before it deteriorates in quality.

- Moisture Absorption

The process by which cement absorbs water from the environment, leading to possible hardening and loss of quality.

- Lumpy Cement

Cement that has hardened into lumps due to moisture exposure, rendering it ineffective.

Reference links

Supplementary resources to enhance your learning experience.