Clinker Formation in Rotary Kiln

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Clinker Formation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will explore the process of clinker formation within the rotary kiln. Can anyone tell me what clinker is?

Isn't clinker the solid material that forms when the raw mixture is heated?

Exactly! In fact, the formation occurs at around 1450°C in the rotary kiln. Let's break down what happens chemically during this process. What do you think happens at such high temperatures?

I guess the materials react with each other?

Correct! The high temperatures cause key reactions that form compounds like C₃S and C₂S. These compounds are vital for the strength of the cement.

What are those compounds made from?

Great question! C₃S is formed from lime and silica, while C₂S is also a product of lime and silica but in different ratios. This information is important for understanding how the cement behaves.

What other compounds are created?

In addition to C₃S and C₂S, we also get C₃A and C₄AF, which come from iron oxides and alumina reacting with lime. Keep these compounds in mind; they play crucial roles in cement performance!

So, if I remember the acronym 'CAC' for C₃A and C₄AF, it helps me recall their importance?

Exactly! The C₃A contributes to early strength, while C₄AF imparts color. To sum up, the clinker formation stage is key in achieving cement's required properties.

Chemical Reactions in Clinker Formation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand what clinker is, let’s discuss the specific chemical reactions involved. Who remembers the high temperature at which these reactions occur?

1450°C!

Exactly! At these temperatures, the calcium carbonate decomposes, and lime is formed. What does this contribute to the process?

It provides the necessary lime for the formation of those silicate compounds.

Correct! Additionally, the formation of C₃S is an important step because it dictates cement's early strength. Let’s review the importance of C₂S.

Doesn’t C₂S help with strength later on?

Exactly! It generally contributes to strength over time. Let’s not forget about C₃A, which reacts rapidly. What do you think happens if there’s too much of it?

The cement might set too quickly!

Yes! Control of these compounds during the clinker formation is crucial to achieve the desired properties in the final cement product.

Significance of Clinker in Cement Production

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

We have covered the reactions quite well. Now, let’s talk about why clinker is so important in cement production. Why do you think it matters?

I think it's because without proper clinker, you can't have good quality cement?

Precisely! The quality of clinker affects the strength and durability of the final cement. Can someone summarize what economic benefits come from efficient clinker production?

If clinker is produced efficiently, it leads to better performance of cement and potentially lower costs.

Exactly! Efficient production reduces waste and has a lower carbon footprint. This brings us to think about why innovations in this area are important.

Innovations can help improve processes while being environmentally friendly!

Very insightful! As we move forward, keep in mind the importance of understanding clinker formation and its implications for the cement industry.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

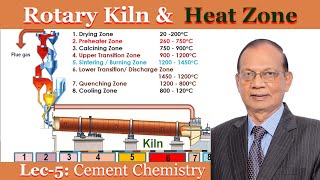

This section discusses the clinker formation process in a rotary kiln at approximately 1450°C, highlighting the significant chemical reactions involved in creating C₃S, C₂S, C₃A, and C₄AF, which are crucial for cement quality and performance.

Detailed

In the rotary kiln, clinker formation represents a vital step in cement manufacturing, taking place at extremely high temperatures around 1450°C. During this phase, several chemical reactions occur. The primary reactions involve the formation of Tricalcium Silicate (C₃S) and Dicalcium Silicate (C₂S) from lime and silica, alongside the reaction of alumina and iron oxides with lime leading to Tricalcium Aluminate (C₃A) and Tetracalcium Aluminoferrite (C₄AF). Understanding these processes is essential for controlling the quality of the final cement product and ensuring it meets required standards in strength and durability.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Critical Stage of Clinker Formation

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The most critical stage, occurring at 1450°C.

Detailed Explanation

Clinker formation is a pivotal part of the cement manufacturing process that occurs at a temperature of approximately 1450°C. At this stage, raw materials undergo significant transformations due to the intense heat. The environment inside the rotary kiln promotes chemical reactions that lead to the formation of clinker, the key component in cement.

Examples & Analogies

Think of baking a cake. Just like how high heat is essential for the ingredients to react and transform into a tasty cake, the extreme temperatures in the rotary kiln help raw materials change into clinker, which is then ground into cement.

Chemical Reactions During Clinker Formation

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Chemical reactions occur to form clinker nodules:

Major reactions:

o Formation of C₃S (Alite) and C₂S (Belite)

o Reaction of alumina and iron oxide with lime to form C₃A and C₄AF

Detailed Explanation

During the clinker formation process, several important chemical reactions take place. The main products are C₃S (tricalcium silicate), C₂S (dicalcium silicate), C₃A (tricalcium aluminate), and C₄AF (tetracalcium aluminoferrite). These compounds are crucial because they determine the properties of the cement, such as strength and setting time. For example, C₃S contributes to the early strength of cement, while C₂S provides strength over time.

Examples & Analogies

Imagine a factory where different ingredients are combined to create various products. In the case of clinker formation, the ingredients (lime, alumina, and iron oxide) are reacting to form specific products (C₃S, C₂S, C₃A, C₄AF) that are necessary for making high-quality cement, just like how combining certain ingredients is crucial for making a delicious dish.

Key Concepts

-

Clinker Formation: The process of creating solid materials at high temperature during cement production.

-

C₃S and C₂S: Key compounds formed during clinker production that significantly influence the strength of the cement.

-

C₃A and C₄AF: Additional compounds formed that affect setting times and color of the cement.

Examples & Applications

When limestone is subjected to high temperatures in a rotary kiln, it undergoes calcination, producing lime, which is then involved in forming C₃S.

The presence of alumina and iron oxide reacts with lime, forming C₃A and C₄AF, which are critical for creating desired cement properties.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

At 1450 degrees, the kiln sings, / Clinker forms and strength it brings!

Stories

Imagine the kiln as a chef, cooking at the highest heat, mixing lime, silica, and alumina in a dance to create the perfect clinker dish!

Memory Tools

Remember CAC: Clinker Always Contributes to cement strength and properties.

Acronyms

C-A-S-S for Clinker

Calcium

Aluminate

Silicate

Strength.

Flash Cards

Glossary

- Clinker

The solid material that forms when raw materials are heated in a rotary kiln, consisting primarily of calcium silicates.

- C₃S (Alite)

Tricalcium silicate, a major compound in clinker, crucial for early strength in cement.

- C₂S (Belite)

Dicalcium silicate, a compound in clinker that contributes to later strength.

- C₃A (Aluminate)

Tricalcium aluminate, a compound that reacts quickly and influences cement setting time.

- C₄AF (Ferrite)

Tetracalcium aluminoferrite, a minor compound contributing to color and some strength characteristics in cement.

Reference links

Supplementary resources to enhance your learning experience.