Bogue’s Compounds

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Tricalcium Silicate (C₃S)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, let's discuss Tricalcium Silicate, also known as C₃S. Can anyone tell me what importance this compound has in cement?

I think it's related to the strength of cement. Is that right?

Exactly! C₃S is responsible for early strength, especially in the first seven days of hydration. That's why we always want a good proportion of it in our cement mix.

How can we remember this?

A good memory aid is the phrase 'C₃S Sets Strong.' It highlights how important C₃S is for initial strength. Can anyone explain why early strength is critical in construction?

It’s important because it allows for quicker construction timelines!

Exactly! Rapid strength gain means less waiting time before further construction can happen. Great job, everyone.

Exploring Dicalcium Silicate (C₂S)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about Dicalcium Silicate, or C₂S. Who can explain its role in cement?

It helps with the strength of cement over a more extended period, right?

That's correct! C₂S mainly contributes to strength beyond seven days. Its slower hydration means it keeps gaining strength as time goes on. How do we remember which compound this is?

Maybe 'C₂S Saves Later' could work?

Excellent mnemonic! Always remember that C₂S saves the day beyond the first week. Anyone knows why this later strength is necessary?

It ensures long-term durability in structures.

Exactly. The longevity of a structure relies significantly on C₂S. Well done!

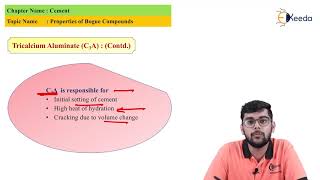

Understanding Tricalcium Aluminate (C₃A)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's now focus on Tricalcium Aluminate, or C₃A. Anyone know how it behaves in concrete?

It makes the cement set quickly!

That's right! C₃A is crucial for fast reaction with water, impacting the early setting time. However, it can be problematic if there's too much. What can happen then?

It might lead to durability issues?

Correct! High amounts can cause expansive reactions, which may crack concrete. A memory tool here could be 'C₃A Accelerates, but Beware!'.

Got it. Don't overload on C₃A!

Exploring Tetracalcium Aluminoferrite (C₄AF)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s discuss Tetracalcium Aluminoferrite, abbreviated as C₄AF. What do we know about this compound?

It has a lower strength contribution and makes cement grey, right?

Absolutely! It contributes less to strength but affects the color of cement. Why is that color important?

It can influence the aesthetic of structures!

Exactly! For visual appeal, C₄AF plays its part. A mnemonic could be 'C₄AF Adds Flavor,' indicating both its role in color and minor strength.

Flavor it is, as long as we manage expectations!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

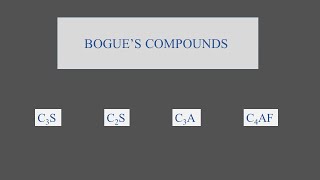

This section discusses Bogue's compounds, which are four key chemical compounds formed during the kiln burning of cement raw materials. These compounds—Tricalcium Silicate, Dicalcium Silicate, Tricalcium Aluminate, and Tetracalcium Aluminoferrite—significantly influence the early strength, later strength, hydration, and color of cement.

Detailed

Bogue’s Compounds

Bogue’s compounds refer to the four primary chemical compounds formed during the clinker production in cement manufacturing. The combination of specific oxides during the kiln burning process results in these compounds, each playing a distinct role in the performance and characteristics of cement. The four main Bogue’s compounds are:

- Tricalcium Silicate (C₃S): This compound is critical for providing early strength in cement. It composes approximately 50-70% of Ordinary Portland Cement (OPC) and is responsible for most of the strength gained within the first 7 days of hydration.

- Dicalcium Silicate (C₂S): Contributing to later strength development, this compound grows in significance after the initial setting time. It typically exhibits slower hydration compared to C₃S, contributing to the long-term durability of concrete.

- Tricalcium Aluminate (C₃A): Known for its rapid reaction with water, C₃A plays a critical role in the early setting time of cement. However, excessive amounts can lead to reduced durability and strength due to its expansive reactions.

- Tetracalcium Aluminoferrite (C₄AF): This compound imparts a grey color to cement and has a low contribution to strength. It's primarily involved in providing some resistance to sulfate attack and enhancing certain properties of the cement mix.

Understanding Bogue’s compounds is essential for engineers and practitioners in selecting the appropriate type of cement for specific construction requirements, thereby impacting the overall performance of concrete structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Bogue's Compounds

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The above oxides combine during kiln burning to form four main compounds, known as Bogue’s compounds:

Detailed Explanation

Bogue's compounds are a set of four primary phases formed during the cement production process when raw materials are subjected to high temperatures in a kiln. These phases are crucial as they define the properties of the finished cement. Understanding these compounds helps one grasp how different compositions affect the behavior and quality of cement in construction applications.

Examples & Analogies

Think of Bogue's compounds as the key ingredients in a recipe for a special dish. Just like how the right combination of spices can alter the taste of food, the unique combinations of these compounds influence the strength and durability of cement.

Tricalcium Silicate (C₃S)

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Tricalcium Silicate (C₃S): 3CaO·SiO₂ - Early strength (initial 7 days)

Detailed Explanation

Tricalcium silicate is one of the most important compounds in ordinary Portland cement. It contributes significantly to the early strength of cement, particularly within the first seven days of hydration. When cement is mixed with water, C₃S reacts quickly to form calcium silicate hydrate, which is a gel-like material that binds the particles together, resulting in increased compressive strength.

Examples & Analogies

Consider a sponge cake that rises quickly after being baked. The ingredients in the cake undergo rapid chemical reactions, causing it to expand and take shape quickly, similar to how C₃S helps cement gain strength shortly after setting.

Dicalcium Silicate (C₂S)

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Dicalcium Silicate (C₂S): 2CaO·SiO₂ - Later strength (after 7 days)

Detailed Explanation

Dicalcium silicate is responsible for the long-term strength of cement. While C₃S provides initial strength, C₂S contributes to the strength development that occurs after the first week. It reacts more slowly with water compared to C₃S, thus its effects become prominent in the later stages of hydration.

Examples & Analogies

Picture a good cup of tea that tastes even better after it has steeped for a while. The flavors enhance and deepen over time. Similarly, Dicalcium Silicate enhances the strength of cement as it ages.

Tricalcium Aluminate (C₃A)

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Tricalcium Aluminate (C₃A): 3CaO·Al₂O₃ - Fast reaction, contributes to early setting

Detailed Explanation

Tricalcium aluminate plays a crucial role in the early setting process of cement. It reacts quickly with water, leading to the formation of hydrates almost immediately after mixing. This quick reaction is beneficial in construction scenarios where rapid setting is essential. However, excessive C₃A can lead to problems such as shrinkage and cracking, especially in high-heat environments.

Examples & Analogies

Think of making instant coffee: when you add hot water, it dissolves quickly and gives you a caffeine boost almost immediately. C₃A acts like this instant coffee, ensuring that cement starts to set and strength develops rapidly when water is added.

Tetracalcium Aluminoferrite (C₄AF)

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Tetracalcium Aluminoferrite (C₄AF): 4CaO·Al₂O₃·Fe₂O₃ - Imparts grey color, low strength contribution

Detailed Explanation

Tetracalcium aluminoferrite is notable for its low contribution to strength compared to the other compounds. Its primary role is to provide color to the cement, as it typically imparts a grey hue. It reacts more slowly and also contributes to the overall setting and hardening characteristics of the cement, but it is not as significant in terms of strength as C₃S or C₂S.

Examples & Analogies

Imagine adding food coloring to a cake batter. While the color enhances the visual appeal of the cake, it doesn’t affect the cake's structural integrity. Similarly, C₄AF adds color to cement but has a minor role in its strength.

Key Concepts

-

C₃S: Provides early strength in cement hydration.

-

C₂S: Contributes to the later strength of cement.

-

C₃A: Accelerates setting time and can be expansive.

-

C₄AF: Affects cement color with minor strength impact.

Examples & Applications

C₃S contributes to a structure's ability to bear loads during the first few days after pouring concrete.

C₂S ensures that a building maintains its structural integrity over many years, highlighting its role in durability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

C₃S is a key for strength so early, C₂S saves strength, keeping concrete sturdy.

Stories

Imagine a race where C₃S finishes first, making concrete ready quickly. Later, C₂S joins in to ensure the strength lasts long after.

Memory Tools

C-A-S-F: C₃S for first strength, C₂S for later, C₃A for speed but be cautious, and C₄AF for color.

Acronyms

S-A-F-C

Remember Strength-Accelerated-First-Cement for Bogue’s compounds.

Flash Cards

Glossary

- Tricalcium Silicate (C₃S)

A compound in cement responsible for early strength development.

- Dicalcium Silicate (C₂S)

A compound that contributes to the long-term strength of cement.

- Tricalcium Aluminate (C₃A)

A compound that accelerates early hydration and setting time.

- Tetracalcium Aluminoferrite (C₄AF)

A compound affecting cement color with low strength contribution.

Reference links

Supplementary resources to enhance your learning experience.