Quality Control in Cement Manufacturing

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Quality Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Quality control is essential in the cement manufacturing process. It ensures that the final product meets the necessary standards for both performance and safety. Can anyone think of why the quality of cement is particularly important?

It needs to be strong and durable for construction, right?

Exactly! The strength and durability of structures depend heavily on the quality of the cement used. Let's break down the different aspects of quality control.

What do we actually test in the raw materials?

Great question, Student_2! We regularly test the chemical and physical properties of raw materials. This helps us ensure that they meet specific properties required for effective cement production. Remember: If the raw materials aren't good, the final product won't be either.

Monitoring Clinker Quality

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

The next step is monitoring clinker quality. Why do you think this is important?

Maybe because clinker is what actually hardens into cement?

Absolutely, Student_3! The clinker composition must be monitored to maintain required levels of C₃S and C₂S content. Can anyone tell me what these compounds do?

C₃S gives initial strength, while C₂S develops strength over time, right?

Exactly! Monitoring these compounds ensures we maintain the strength and durability of the cement.

Final Product Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

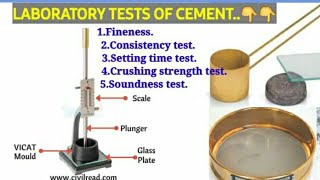

Now let’s talk about final product testing. What tests do we perform to ensure quality?

There's the fineness test, the setting time test, right?

Correct! The fineness test uses Blaine’s method to evaluate the surface area of cement. Does anyone remember why this is important?

Finer cement hydrates faster and achieves strength quicker!

Exactly! We also check the setting time to make sure it’s suitable for construction applications. Too quick or too slow can cause issues. What other tests do we have?

Soundness testing and compressive strength testing!

Right! Soundness testing ensures the cement doesn’t expand too much after setting. Excellent recall everyone!

Summary of Quality Control Measures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To wrap things up, let's summarize the key points we discussed about quality control in cement manufacturing. What are the main areas we focused on?

We talked about raw material testing and clinker quality monitoring.

Great! And what tests do we conduct on the final product?

Fineness, setting time, soundness, and compressive strength tests!

Exactly! These measures are crucial for ensuring the quality and reliability of cement, which ultimately affects the safety of structures built with it. Thank you for your participation today!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Quality control in cement manufacturing involves testing raw materials, monitoring clinker quality, and conducting final product tests. Key performance indicators include fineness, setting time, soundness, and compressive strength, all of which are critical to cement's performance in construction.

Detailed

Quality Control in Cement Manufacturing

Quality control is crucial in cement manufacturing as it directly influences the properties and performance of the final product. This section highlights several key processes and tests:

- Raw Material Testing: Regular assessment of the chemical and physical properties of raw materials ensures they meet specifications before production begins.

- Clinker Quality Monitoring: The composition of clinker is monitored to ensure optimal levels of C₃S (tricalcium silicate) and C₂S (dicalcium silicate) are achieved, as these compounds significantly contribute to the strength and durability of cement.

- Final Product Testing: A series of tests are conducted on the finished cement, including:

- Fineness Testing: Assessed using Blaine’s air permeability test to determine surface area, which affects hydration and early strength.

- Setting Time Testing: Initial and final setting times are tested to ensure they are within acceptable limits for application.

- Soundness Testing: Conducted using Le Chatelier test to ensure the cement maintains volume stability after setting.

- Compressive Strength Testing: Standard mortar cubes are tested to measure the cement's ability to withstand pressure over time.

By implementing these quality control measures, manufacturers can ensure that the cement produced not only meets the required technical standards but also performs reliably in construction applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Raw Material Testing

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Raw Material Testing: Chemical and physical properties of raw materials are tested regularly.

Detailed Explanation

In cement manufacturing, the quality of raw materials is crucial because it influences the final product. Regular testing ensures that the chemical and physical properties of materials like limestone and clay meet specific standards. For instance, the limestone should have the right level of calcium carbonate to produce quality lime, which is essential for making cement. Regular testing helps in identifying any potential deviations early in the process.

Examples & Analogies

Think of raw material testing like a health check-up for the ingredients we use in cooking. Just as we inspect vegetables for freshness and quality before making a meal, manufacturers check raw materials to ensure they are suitable for cement production.

Clinker Quality Monitoring

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Clinker Quality: Clinker composition is monitored to maintain the required C₃S and C₂S content.

Detailed Explanation

Clinker is a crucial intermediate product in cement manufacturing. Its composition should have a specific balance of C₃S (tricalcium silicate) and C₂S (dicalcium silicate) since these compounds significantly affect the strength and setting properties of the cement. Regular monitoring ensures these compounds are within desirable limits, which directly impacts the quality and performance of the final cement product.

Examples & Analogies

Consider the clinker composition monitoring as like ensuring the right blend of tea leaves in your favorite brew. Too much of one type may spoil the flavor, just as incorrect proportions of C₃S and C₂S can impair the cement's strength.

Final Product Testing

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Final Product Testing: The cement is tested for:

- Fineness (Blaine’s air permeability test)

- Setting time (initial and final)

- Soundness (Le Chatelier test)

- Compressive strength (standard mortar cube)

Detailed Explanation

Once the cement is produced, it undergoes several tests to ensure it meets industry standards. Fineness is checked using Blaine’s air permeability test to assure that the particles are small enough for quick hydration. The setting time is assessed to determine how long the mix remains workable. The soundness test ensures that the cement does not expand or contract excessively after setting, which could lead to cracking. Finally, compressive strength tests on mortar cubes determine how much load the cement can bear once it has cured.

Examples & Analogies

You can think of final product testing as the quality checks done at a bakery once a cake is baked. Just like bakers check if the cake is fluffy, moist, and holds its shape, manufacturers conduct these tests to confirm that the cement will perform well in construction.

Key Concepts

-

Quality Control: The systematic process to maintain product quality.

-

Raw Material Testing: Ensures materials meet specifications before production.

-

Clinker Quality: Monitoring clinker composition to achieve desired cement properties.

-

Final Product Testing: Includes fineness, setting time, soundness, and compressive strength assessments.

Examples & Applications

In a cement plant, the fineness of cement is tested using Blaine’s air permeability method, which can help predict its hydration behavior.

If the tested compressive strength of cement mortar cubes fails to meet the standards, adjustments to the manufacturing process may be needed.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For cement so fine, let it pass the test, / With quality control, we know it's the best!

Stories

Imagine a builder ready to construct a tall building. He insists on quality control at every step, ensuring the cement used is strong enough to hold his creation, knowing that any compromise could lead to disaster.

Memory Tools

Remember the ACTS for final product testing: A for Fineness, C for Compressive Strength, T for Time (setting), and S for Soundness.

Acronyms

Use the acronym 'QC' for Quality Control—quick checks lead to quality cement!

Flash Cards

Glossary

- Quality Control

Systematic measures to ensure that products meet certain quality standards.

- Clinker

The intermediate product of cement manufacturing that is produced by heating limestone and clay.

- Fineness Test

A test that measures the surface area of cement particles to determine hydration rate.

- Setting Time

The time taken for cement to lose plasticity after mixing with water.

- Soundness Test

A test to ensure that cement does not expand excessively after hardening.

- Compressive Strength

The ability of cement to withstand axial loads; measured using mortar cube tests.

Reference links

Supplementary resources to enhance your learning experience.