Proportioning and Blending

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Proportioning

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are diving into the process of proportioning in cement manufacturing. Why do you think it’s crucial to get the proportions right?

Because if the proportions are wrong, the strength of the cement might be affected!

Exactly! Accurate proportioning ensures that the chemical composition is uniform. We generally use gravimetric or volumetric feeders. Can anyone explain what they think gravimetric feeders do?

They weigh the raw materials to make sure the amounts are correct, right?

Yes, great job! Gravimetric feeders weigh materials accurately, while volumetric feeders measure by volume. Let’s remember: 'Weight is Great (for accuracy)!' Can anyone tell me why blending is important after proportioning?

To make sure everything mixes well before it goes into the kiln?

Absolutely! Uniform blending leads to consistent quality in cement. Let’s recap: proper proportioning and blending lead to stronger cement. Remember this acronym: 'PB = Proportioning + Blending = Performance Boost!'

Blending Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s explore how blending works. What techniques do you think are commonly used in cement factories?

I think they use modern machines to mix everything really well.

Correct! Advanced blending machines help achieve uniformity. Do you know why maintaining uniform chemical composition is crucial?

If it’s not uniform, we might end up with weaker cement that's not reliable for construction.

Exactly! A consistent mixture leads to more durable cement. Remember this: 'Blending = Stronger Bonding!' Let’s analyze the impact of poor blending. What might happen in the final cement quality?

It could cause cracks in concrete later on!

Right! Defects manifest later due to poor blending. Summarization: Correct blending reduces defects – simple but vital!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Proportioning and blending are essential stages in cement production that utilize gravimetric or volumetric feeders to mix raw materials in precise amounts. This section highlights the importance of achieving a uniform chemical composition in the final product to enhance the strength and quality of cement.

Detailed

Proportioning and Blending

In the cement manufacturing process, proportioning and blending of raw materials are crucial for ensuring the final product meets desired chemical and physical characteristics. This section focuses on the process used to determine the right proportions of different materials in cement production, primarily using gravimetric or volumetric feeders. Proper blending ensures a consistent chemical composition, which directly impacts the performance attributes of the cement, such as durability and strength. Effective proportioning and blending are essential to achieve optimal results in the subsequent manufacturing stages.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Proportioning of Raw Materials

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The raw materials are proportioned using gravimetric or volumetric feeders.

Detailed Explanation

In cement manufacturing, it's crucial to use the correct amounts of raw materials, which often include limestone and clay. Proportioning is the process where these materials are measured accurately before being processed further. There are two main methods for proportioning:

- Gravimetric Feeders: These feeders use weight to measure the amount of material. By weighing out the materials, manufacturers ensure that the precise amount is used in the mix. This is important because slight variations can affect the final product’s quality.

- Volumetric Feeders: In this method, the materials are measured based on volume instead of weight. While volumetric feeders are generally simpler and faster, they can be less accurate compared to gravimetric feeders, especially when dealing with materials of varying densities.

Correct proportioning helps maintain the quality and consistency of the cement produced.

Examples & Analogies

Think of a recipe for a cake. If you use too much flour or too little sugar, it can change the taste and texture of the cake. Similarly, in cement production, if the proportions of raw materials are wrong, the cement product can be of poor quality, similar to a poorly made cake.

Blending of Raw Materials

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

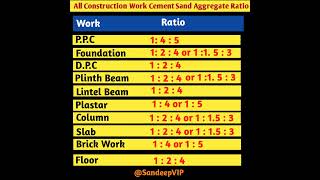

Proper blending ensures uniform chemical composition in the final product.

Detailed Explanation

Once the raw materials have been proportioned accurately, the next step is blending. Blending refers to mixing the raw materials thoroughly to achieve a uniform chemical composition. This is important because it ensures that every batch of cement has the same properties.

Uniformity in chemical composition is critical for several reasons:

- Consistency: It helps in maintaining the same performance standards across different batches of cement.

- Performance: A well-blended mix contributes to the strength and durability of the final concrete product. Inconsistencies in blending can lead to variances in how the cement performs when mixed with water and aggregates.

Mixing equipment often used includes paddle mixers or revolving drums, which ensure that all the materials are combined evenly.

Examples & Analogies

Consider mixing paint. To get the right color and finish, you need to blend the paint colors thoroughly. If some parts are darker or lighter, the wall won’t look uniform. In cement, if the raw materials aren’t blended well, you can end up with inconsistent quality, just like how uneven paint can ruin the look of a room.

Key Concepts

-

Proportioning: The accurate measurement of raw materials necessary for optimal cement quality.

-

Blending: The mixing of proportioned materials to ensure a uniform chemical composition in the final product.

-

Feeders: Devices used in the proportioning process; gravimetric and volumetric feeders are commonly utilized.

Examples & Applications

Using gravimetric feeders, a cement plant accurately weighs limestone and clay to create a specific blend for OPC.

Common blending techniques involve using modern mixers that help achieve uniformity in raw material before it goes into the kiln.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When mixing cement to build a wall, proportioning is the key for strength to stand tall.

Stories

Imagine a baker mixing flour and sugar. If he doesn't measure correctly, the cake will not rise. Similarly, in cement mixing, accurate proportions lead to a durable mixture.

Memory Tools

PB = Proportioning and Blending, essential for strong cement ending! (PB for Performance Boost!)

Acronyms

FAB = Feeders Are Better for accurate mixing! (F for feeders, A for accurate, B for blending.)

Flash Cards

Glossary

- Gravimetric Feeders

Devices that weigh the raw materials to ensure accurate proportions in the manufacturing process.

- Volumetric Feeders

Devices that measure the raw materials by volume for blending in cement production.

- Blending

The process of mixing raw materials to ensure uniform chemical composition and quality.

Reference links

Supplementary resources to enhance your learning experience.