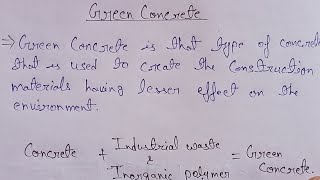

Green Cement

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Green Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Good morning, everyone! Today, we are diving into an important shift in our construction materials: green cement. Can anyone tell me what they think green cement might be?

Is it cement that is environmentally friendly?

Exactly! Green cement aims to reduce the environmental impact of traditional cement production. Now, why do you think this is important?

Because traditional cement-making releases a lot of CO₂, right?

That's right! Traditional methods can produce significant carbon emissions. By using green cement, we can cut down on that carbon footprint, which is a big step towards sustainability.

Materials and Methods in Green Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's explore what makes green cement different in terms of materials. Can anyone name some alternative materials that might be used?

What about using waste materials from other industries?

Great point! Green cement often incorporates industrial by-products, which helps reduce waste. For instance, alkali-activated binders and geopolymers are popular alternatives. Do you think you could connect these concepts with what we learned about cement production?

Yeah! Instead of just using limestone, they use other materials that may not pollute as much!

Absolutely! This approach not only decreases emissions but also utilizes materials that would otherwise go to waste.

Limestone Calcined Clay Cement (LC₃)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Have any of you heard of limestone calcined clay cement, or LC₃?

No, what is it?

LC₃ is a green cement alternative that combines limestone and calcined clay, and it improves sustainability. Why do you think combining those two materials might be beneficial?

Maybe it helps keep the strength of regular cement but reduces emissions?

Exactly! LC₃ offers a performance comparable to conventional cements while significantly lowering its environmental impact. Remember the S in LC₃? It stands for sustainability!

The Future of Green Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Where do you see green cement fitting into the future of construction?

I think it will become more common as we try to be more eco-friendly.

That’s a great insight! As construction practices evolve, green products will likely take center stage. What might be some challenges in adopting these materials?

Maybe people are used to traditional methods and don't want to change?

Indeed! Changing industry practices can be tough, but innovations in green cement show that it’s possible, paving the way for a more sustainable future.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Green cement represents a shift towards more sustainable construction materials, focusing on reducing carbon emissions through innovative alternatives, such as alkali-activated binders and geopolymers. This section elaborates on the characteristics and significance of green cement in modern construction techniques.

Detailed

Green Cement

Green cement is a vital innovation in the construction industry aimed at minimizing the environmental impact associated with traditional cement production. Traditional cement manufacturing is notorious for its high carbon emissions, primarily due to the calcination process of limestone and the combustion of fossil fuels in kilns.

Key Features of Green Cement

- Lower Carbon Footprint: The production of green cement involves techniques that significantly reduce CO₂ emissions compared to conventional methods.

- Alternative Materials: It often incorporates eco-friendly materials such as alkali-activated binders and geopolymers that utilize industrial by-products, contributing to waste minimization.

- Limestone Calcined Clay Cement (LC₃): This emerging material combines limestone and clay to enhance sustainability without compromising on performance. The properties of LC₃ make it a viable alternative to traditional cements.

These innovative approaches not only offer improved sustainability but also enhance the performance of cement-based materials, underscoring the importance of green technologies in the future of construction.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Lower Carbon Footprint

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Lower carbon footprint.

Detailed Explanation

Green cement is designed to have a lower carbon footprint compared to traditional cement. This means it contributes less to climate change and reduces greenhouse gas emissions during its production. The lowering of carbon emissions is achieved through the use of alternative materials and processes that are less energy-intensive.

Examples & Analogies

Think of it like choosing to ride a bicycle instead of driving a car. Riding a bicycle produces no emissions and is much better for the environment than driving, similar to how green cement minimizes its environmental impact compared to regular cement.

Innovative Manufacturing Techniques

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Manufactured using alkali-activated binders, geopolymers, or limestone calcined clay cement (LC³).

Detailed Explanation

Green cement can be produced using several innovative methods. Alkali-activated binders involve using industrial by-products and require less energy in production. Geopolymers are made from materials rich in alumina and silica but do not require high temperatures, saving energy. Limestone calcined clay cement (LC³) combines limestone and clay, which also reduces CO₂ emissions during the manufacturing process.

Examples & Analogies

This is akin to cooking with leftovers instead of fresh ingredients. Using what you already have reduces waste and conserves resources, just as manufacturers can create green cement with less environmental impact by utilizing alternative materials.

Key Concepts

-

Environmental Impact: Green cement aims to reduce the carbon footprint associated with cement production.

-

Sustainable Materials: Incorporates eco-friendly materials, such as alkali-activated binders and geopolymers.

-

Limestone Calcined Clay Cement (LC₃): A specific type of green cement that combines limestone and clay for enhanced sustainability.

Examples & Applications

Using industrial by-products like fly ash in green cement reduces landfill waste and CO₂ emissions.

LC₃ shows comparable strength to traditional cement while using less energy in its production.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cement that's green, keeps the air clean.

Stories

Imagine a construction site using traditional cement. The air is thick with dust, and the atmosphere feels heavy. Now picture the same site using green cement; it buzzes with life, plants growing nearby, and workers proud of their eco-friendly choice.

Memory Tools

G.A.L.C.: Green cement, Alkali-Activated binders, Limestone, Calcined clay.

Acronyms

GLC

Green

Limestone

Clay - important components of sustainable cement!

Flash Cards

Glossary

- Green Cement

Cement designed to lessen environmental impact by utilizing alternative materials and reducing CO₂ emissions.

- AlkaliActivated Binders

Cementitious materials that are activated by alkaline solutions, often utilizing industrial by-products.

- Geopolymers

Synthetic polymers with cement-like properties, created from inorganic aluminosilicate materials.

- Limestone Calcined Clay Cement (LC₃)

A sustainable cement that combines limestone and calcined clay for improved performance and reduced emissions.

Reference links

Supplementary resources to enhance your learning experience.