Cement Testing in Laboratories

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Fineness Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're focusing on the fineness test of cement. Can anyone tell me why fineness is important?

I think finer cement has a better surface area, which might help it hydrate more quickly.

Exactly! Greater fineness increases the surface area, leading to faster hydration and early strength development. We measure fineness using Blaine’s air permeability apparatus or sieve analysis. Who can guess how this influences concrete performance?

If it hydrates faster, does that mean the concrete can set earlier too?

Yes! It translates into quicker initial strength gains. So, we assess fineness to ensure quality standards. Can someone summarize what we just discussed about the fineness test?

Fineness is important for hydration speed and early strength, and we test it using specific methods like Blaine’s.

Great summary! Remember, finer cement improves hydration and contributes to stronger concrete.

Consistency Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s delve into the consistency test. Why do you think knowing the water content for normal consistency is significant?

It probably affects how the cement interacts with water during mixing and curing?

Correct! Using Vicat’s apparatus, we determine the ideal water content. This influences other tests for setting time and soundness. What implications could incorrect water content have?

If it’s too much or too little, it could lead to weak cement or improper setting.

Exactly right! Consistency is crucial for ensuring the cement performs as expected. Can someone recap the purpose of the consistency test?

The consistency test determines the water needed for normal consistency using Vicat’s apparatus.

Perfect! Understanding consistency helps us maintain overall quality in cement applications.

Setting Time Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about the setting time test. Why do we need to measure initial and final setting times?

I imagine it helps in knowing when the cement can be worked with and when it’s fully set?

Exactly! The initial setting time tells us when we lose plasticity—at least 30 minutes as per IS code. Meanwhile, the final setting time indicates when hardening is complete, which should not exceed 600 minutes. Why do you think these timings are crucial?

If they’re not right, the work might get affected, like if it sets too quickly or takes too long?

Right on! Incorrect timings can lead to significant issues in construction. Can someone summarize the key points about the setting time test?

We measure the initial and final setting times to ensure the cement’s workability and proper hardening times.

Excellent job! Understanding setting times is critical for successful cement applications.

Soundness Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we’ll discuss the soundness test. What is the significance of measuring volume stability?

It might show us if the cement expands too much after setting, which could be a problem.

Exactly! We use Le Chatelier’s apparatus to ensure the cement does not undergo excessive expansion. Why is it essential to prevent this?

Excessive expansion could cause cracking or structural failure in concrete structures.

Yes! Maintaining soundness is vital for structural integrity. Can anyone recap the role of the soundness test in cement quality?

The soundness test checks the cement’s volume stability to prevent excessive expansion after setting.

Well done! Understanding soundness directly impacts the long-term durability of our constructions.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Laboratory tests for cement, including fineness, consistency, setting times, soundness, and compressive strength, are conducted to verify quality and performance standards, ensuring that the cement used in construction meets necessary requirements.

Detailed

Cement Testing in Laboratories

Cement testing in laboratories is essential to ensure that the material meets required standards for construction. This section describes several key laboratory tests conducted to assess cement quality:

Key Tests for Cement:

- Fineness Test: Conducted using Blaine’s air permeability apparatus or sieve analysis. The fineness of cement influences hydration and strength; higher fineness results in faster hydration and early strength development.

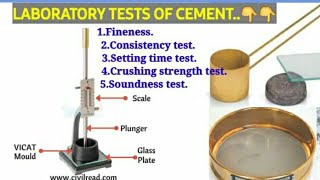

- Consistency Test: This test determines the water content necessary for achieving normal consistency using Vicat’s apparatus, which is pivotal for other tests including setting time and soundness.

- Setting Time Test: Measures the initial setting time, indicating the point at which cement begins to lose plasticity (minimum of 30 minutes). The final setting time indicates when the cement has fully hardened, ideally not exceeding 600 minutes.

- Soundness Test: This test assesses volume stability through Le Chatelier’s apparatus, ensuring that the cement does not undergo excessive expansion after setting, which can compromise structural integrity.

- Compressive Strength Test: Conducted on mortar cubes with a 1:3 cement to sand ratio. The cubes are cured in water for 3, 7, and 28 days, with the OPC 53 grade requiring a minimum strength of 53 MPa after 28 days.

These tests are critical for maintaining the quality and performance of cement used in construction, helping prevent failures in structural integrity and ensuring compliance with established standards.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Fineness Test

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

1.12.1 Fineness Test

- Measured using Blaine’s air permeability apparatus or sieve analysis.

- Greater fineness → higher surface area → faster hydration → early strength.

Detailed Explanation

The fineness test is crucial in assessing how finely cement particles are ground. This is typically measured using Blaine's air permeability apparatus or conducted via sieve analysis. When cement is finer, it has a larger surface area that is exposed when mixed with water. This larger surface area leads to quicker hydration, allowing the cement to gain strength more rapidly. Therefore, the fineness of cement directly impacts its performance in construction.

Examples & Analogies

Think of cement particles like sugar granules. If you have coarse sugar, it takes longer to dissolve in water compared to finely powdered sugar, which dissolves almost instantaneously. Similarly, finer cement will hydrate faster, helping the concrete to attain strength sooner.

Consistency Test

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

1.12.2 Consistency Test

- Determines the water content required for normal consistency using Vicat’s apparatus.

- Important for other setting time and soundness tests.

Detailed Explanation

The consistency test measures the water content needed to achieve a normal consistency in the cement paste using Vicat’s apparatus. This test is vital because the correct consistency influences the subsequent properties of the cement, including setting times and soundness (how stable the cement remains over time). Having an appropriate consistency ensures that the cement can develop proper strength and does not prematurely set.

Examples & Analogies

Imagine you're baking a cake. If your batter is too dry, the cake won't rise properly and will be dense. If it's too wet, it may not hold its shape. Similarly, the right consistency in cement ensures it's workable and will achieve desired performance.

Setting Time Test

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

1.12.3 Setting Time Test

- Initial setting time: Time taken to lose plasticity (minimum 30 minutes as per IS code).

- Final setting time: Time to complete hardening (max 600 minutes).

Detailed Explanation

The setting time test assesses how long it takes for the cement to begin setting (initial setting time) and how long it takes to completely harden (final setting time). According to standards, the initial setting time should be at least 30 minutes, and the final setting time should not exceed 600 minutes. This information is crucial for builders, as it determines how long they have to work with the cement before it hardens.

Examples & Analogies

Think of cement as being like ice cream. When you first take it out of the freezer, it's soft and workable. If you don't serve it within a few minutes, it starts to become too hard to scoop. The setting time of cement is like that window of time when the ice cream is just right for serving.

Soundness Test

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

1.12.4 Soundness Test

- Measures volume stability using Le Chatelier’s apparatus.

- Ensures cement does not expand excessively after setting.

Detailed Explanation

The soundness test checks how stable the cement is in terms of volume using Le Chatelier’s apparatus. It is essential to ensure that the cement does not expand excessively after it has set, which could lead to cracking or failure of the concrete structure. Excessive expansion could indicate the presence of unreacted compounds that could cause future problems.

Examples & Analogies

Imagine inflating a balloon. If you overinflate it, it can pop, causing a mess. Just like that, if cement expands too much, it can crack and lead to structural faults. The soundness test helps to ensure that the 'balloon' of cement remains stable.

Compressive Strength Test

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

1.12.5 Compressive Strength Test

- Conducted on mortar cubes (1:3 cement:sand ratio).

- Cured in water for 3, 7, and 28 days.

- Minimum strength for OPC 53 grade = 53 MPa (after 28 days).

Detailed Explanation

The compressive strength test measures the ability of cement to withstand axial loads. This is usually done by preparing mortar cubes with a 1:3 ratio of cement to sand and curing them in water for 3, 7, and 28 days. After these periods, the strength is tested and recorded. For OPC 53 grade cement, the minimum required compressive strength after 28 days is 53 MPa. This test is critical as it determines whether the cement can support the intended loads in construction.

Examples & Analogies

Think of buildings like bridges or towers requiring strong foundations. It's like testing the strength of a rope. If a rope can hold 100 kg, it's essential to ensure it can consistently perform that way under weight. Similarly, the compressive strength test ensures cement can handle the weight and forces of structures long-term.

Key Concepts

-

Fineness Test: Determines the surface area of cement, affecting hydration and strength gains.

-

Consistency Test: Assesses the water content required for optimal performance.

-

Setting Time Test: Measures the timing related to the loss of plasticity and full hardening.

-

Soundness Test: Ensures cement does not expand excessively after setting, maintaining structural integrity.

-

Compressive Strength Test: Evaluates the strength of cement under load through mortar cubes.

Examples & Applications

A finer cement may lead to a faster setting time due to increased surface area.

If the water content for consistency is incorrect, the cement may set too quickly, leading to a weaker mix.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Fineness test is a must, for strong cement we trust; Consistency is key, for solid work, you see.

Stories

Once, in a big construction site, the workers had cement that was too coarse. They used the fineness test and adjusted it, leading to strong structures that stood the test of time.

Memory Tools

To remember the tests: F - Fineness, C - Consistency, S - Setting time, S - Soundness, C - Compressive strength (FCSSS - ‘Fancy Construction Strongly Stands’)!

Acronyms

C-CCSS

for compressive strength

for consistency

SS for soundness

and C for fineness. Remember C-CCSS for a complete cement evaluation!

Flash Cards

Glossary

- Fineness Test

A test measuring the surface area of cement, significantly affecting hydration rates and strength.

- Consistency Test

A test determining the necessary water content for normal consistency in cement using Vicat’s apparatus.

- Setting Time Test

A test to determine both the initial and final setting times of cement, key for workability and setting properties.

- Soundness Test

A test measuring the volume stability of cement to ensure it does not excessively expand upon setting.

- Compressive Strength Test

A test determining the ability of cement to withstand axial loads, measured through mortar cube strength.

Reference links

Supplementary resources to enhance your learning experience.