Storage and Packaging

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Storage

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll cover how cement is stored. Why do you think storage is important for maintaining cement quality?

Maybe to keep it dry? Water could ruin the cement?

Yes, if cement absorbs moisture, it could lose strength!

Exactly! Storing cement in silos prevents moisture buildup and ensures it stays dry. This way, the cement's properties remain intact until it's used.

What about temperature? Does that affect storage too?

Good point! Maintaining a controlled environment helps preserve the quality of the cement. Let's remember: Silo = Storage = Safety for cement!

Packaging of Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's talk about how cement is packaged. What are the common ways cement is delivered?

Are there big bags or something?

I think they use small bags too, like 50 kg ones?

That's right! Cement is commonly packaged in 50 kg bags for smaller projects. But what if a large construction site needs much more cement?

They might get it in bulk using tankers!

Exactly! This way, contractors can efficiently supply large amounts as needed. Remember, packaging makes cement versatile for different projects.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Cement is stored in silos to maintain its quality and to prevent moisture absorption. It can be packaged in 50 kg bags or supplied in bulk via tankers, which are key aspects of its final stages before reaching construction sites.

Detailed

Storage and Packaging

The storage and packaging of cement are critical steps in its manufacturing process, ensuring that the product maintains its quality and performance until it reaches the customer. After the grinding process, the final cement product is stored in large silos, which protect it from moisture and environmental factors that could compromise its properties.

Silos

Cement is typically kept in silos where it can be maintained in a controlled environment to prevent moisture ingress and to avoid clumping or degradation of the material.

Packaging Options

The packaged cement is often distributed in bags of approximately 50 kg, which makes it suitable for retail sale and small-scale construction needs. For larger projects, cement can also be supplied in bulk via tankers, allowing for efficient transportation and delivery to sites where significant amounts of material are required. This adaptability in storage and packaging caters to various market needs, balancing accessibility for smaller projects with the logistical demands of larger constructions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Storage of Cement

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The final product (cement) is stored in silos.

Detailed Explanation

Cement, once produced, needs to be stored properly to maintain its quality until it is ready for use. The primary method of storage is in silos, which are large, sealed containers that protect the cement from moisture and contamination. Storing in silos helps preserve the cement's integrity and prevents it from clumping together.

Examples & Analogies

Think of how we preserve food. Just like we use airtight containers to keep our snacks fresh and prevent them from going stale, cement is stored in silos to keep it dry and in its best condition.

Packaging of Cement

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

It is packed in bags (usually 50 kg) or supplied in bulk through tankers.

Detailed Explanation

Cement is typically packaged for distribution in two main ways: bags and bulk supply. The bags generally weigh around 50 kg, making them convenient for transport and handling. Bulk supply involves delivering large quantities of cement via tankers, which can be more efficient for large construction projects that require significant amounts of cement at once. This method reduces packaging waste and can lower costs for larger orders.

Examples & Analogies

Imagine ordering flour for baking. If you're making small batches of cookies, you'd buy small bags at the store. But if you're a bakery that sells a lot of bread, you'd order flour in bulk from a supplier. This is similar to how cement is provided to customers according to their needs.

Key Concepts

-

Storage: Cement should be stored in silos to protect it from moisture and contamination.

-

Packaging: Cement is commonly packaged in 50 kg bags or supplied in bulk via tankers.

Examples & Applications

Cement stored in large silos is used in major infrastructures like bridges.

Small 50 kg bags of cement are often available in hardware stores for residential projects.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cement in a silo, to keep it nice and dry, helps it stay strong, oh me, oh my!

Stories

Imagine a giant silo standing tall in the factory—it's like a castle for cement, keeping it safe from rain and dirt!

Memory Tools

Remember 'SBS' for Storage, Bags, and Supply.

Acronyms

Use 'SAB' for Silo, Airtight, Bags.

Flash Cards

Glossary

- Silo

A tall structure for storing bulk materials like cement, protecting it from moisture and contamination.

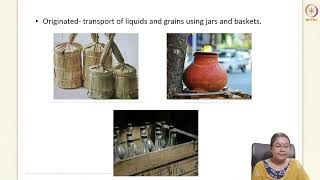

- Packaging

The method of enclosing products, in this case, cement, typically in bags or bulk containers for distribution.

Reference links

Supplementary resources to enhance your learning experience.