Setting Time Test

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Initial Setting Time

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to discuss the initial setting time of cement. Can anyone tell me what that means?

Isn’t it the time it takes for the cement to start hardening?

Exactly! The initial setting time is how long it takes for cement to lose its plasticity. According to IS code standards, this should be a minimum of 30 minutes. Why do you think this time is important?

It probably gives us time to work with the cement before it hardens.

Yes! It's crucial for ensuring that cement can be properly blended and placed. Remember, you can think of it as a window of opportunity where the cement remains workable. We can use the acronym 'PRACTICE': Plasticity Requires A Control in Time for Initial Cement Examination.

So, if the setting time is shorter than 30 minutes, it might not be usable?

That's correct! If it sets too quickly, it can lead to complications in construction. Let’s sum up: the initial setting time is vital for workability, and it should be at least 30 minutes.

Final Setting Time

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's move on to final setting time. Who can explain what final setting time indicates?

Isn't that the time it takes for the cement to completely harden?

Exactly! Final setting time is how long it takes for cement to achieve complete hardness. The maximum time allowed is 600 minutes, which is crucial for ensuring that the cement can carry the loads it will face in a structure. Why do you think this is important?

Because if it takes too long, it could delay the construction process.

Absolutely! Delays can lead to cost overruns and scheduling conflicts. Think of final setting time as the 'endpoint for stress'; it marks when cement can start bearing loads. We can use the mnemonic 'HARDEN'—Hardness Achieves Reliability and Durability, Ensuring Nature’s demands.

So, both times are essential for proper planning?

Correct! To conclude, the final setting time should not exceed 600 minutes for effective use in construction.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the Setting Time Test in cement testing, focusing on the initial setting time—the duration for cement to lose its plasticity—and the final setting time, which indicates how long the cement takes to fully harden. Both timings are crucial for ensuring the appropriate use of cement in construction as per IS code regulations.

Detailed

Setting Time Test: Overview

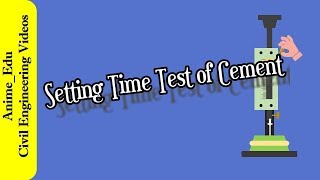

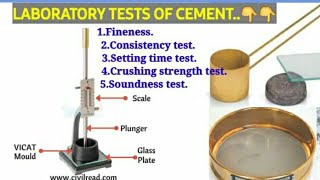

The Setting Time Test is a critical examination conducted to determine how well cement performs in the initial phases of hydration. Specifically, it measures two important aspects:

- Initial Setting Time: Refers to the time it takes for cement to lose its plasticity, marking a transition from a workable state to a stiff state. It is essential for ensuring that the concrete can be placed and finished effectively before it hardens. According to IS code regulations, a minimum initial setting time of 30 minutes is mandated.

- Final Setting Time: This indicates the time taken for the cement to fully harden. The maximum allowable time is 600 minutes as per the IS code, ensuring that the cement achieves sufficient strength prior to being subjected to load.

Understanding these time parameters helps in achieving the desired mechanical properties in cement and aids civil engineers in planning construction schedules effectively. Any deviations from these timeframes can have significant implications on construction timelines and structural integrity.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Initial Setting Time

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Initial setting time: Time taken to lose plasticity (minimum 30 minutes as per IS code).

Detailed Explanation

The initial setting time refers to the duration it takes for the cement to begin to harden after it is mixed with water, effectively losing its plasticity. According to the Indian standards, this time must be at least 30 minutes, meaning that within this period, workers must be able to manipulate and shape the cement mix for construction purposes without it hardening too quickly.

Examples & Analogies

Think of making a clay sculpture. When you first shape the clay, it's soft and pliable, just like cement in its initial setting phase. You have a limited amount of time before the clay starts hardening, making it difficult to add details. Just as clay needs that moment to be molded, cement also needs time for workers to shape it before it sets.

Final Setting Time

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Final setting time: Time to complete hardening (max 600 minutes).

Detailed Explanation

The final setting time indicates the period taken for the cement to fully harden after mixing with water. This time limit is capped at 600 minutes. Once this time has elapsed, the cement should have transitioned from a viscous material to a hardened form, ready for structural purposes. This measurement ensures that the cement behaves predictably and performs well in its role.

Examples & Analogies

Consider baking a cake. You mix the ingredients, and there's a crucial time at which the batter transforms into a solid cake. Just like in baking, where you can’t take the cake out too soon or it will be doughy, cement also has a specific final setting period. Once it reaches this point, it cannot be molded further, much like how a fully baked cake is ready to eat.

Key Concepts

-

Initial Setting Time: The duration cement remains workable before hardening.

-

Final Setting Time: The total time until cement achieves full hardness.

Examples & Applications

Example of a cement batch used on-site exceeding the 30-minute initial setting time might lead to difficulties in spreading and finishing.

When final setting time exceeds 600 minutes, the amount of usable time for laying concrete is affected, which could disrupt project schedules.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Setting time must be just right, 30 and 600 keeps construction tight.

Stories

Imagine a construction worker who is having a race against time. As he mixes his cement, he keeps an eye on a clock. If he doesn't complete his work before the 30-minute mark, his cement will harden, only leaving him with a solid block instead of a usable mix!

Memory Tools

Remember the phrase 'Every Minute Counts' refers to initial setting time of 30 minutes and final setting time not exceeding 600 minutes.

Acronyms

The acronym 'SET' - Safety Ensured Through understanding Initial and Final setting times.

Flash Cards

Glossary

- Initial Setting Time

The time taken for cement to lose plasticity, with a minimum requirement of 30 minutes as per IS standards.

- Final Setting Time

The total time required for cement to completely harden, which should not exceed 600 minutes according to IS standards.

Reference links

Supplementary resources to enhance your learning experience.