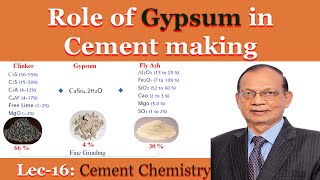

Role of Gypsum in Cement

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Gypsum in Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing the role of gypsum in cement. Can anyone tell me what would happen if we didn't use gypsum?

Wouldn’t the cement set too fast for us to work with it?

Exactly! Without gypsum, cement would set nearly instantly upon mixing with water. This is why gypsum acts as a retarder.

So, how much gypsum do we need to add?

Great question! Typically, we add about 3-5% gypsum during the grinding of clinker. This helps control the setting process.

What does it mean that gypsum delays the hydration of C₃A?

Hydration of C₃A is crucial because its rapid hydration can lead to immediate setting. Gypsum's presence allows time for mixing and application.

Can you summarize the key points for us?

Of course! Gypsum is vital for controlling the setting time of cement, allowing 3-5% to be added during clinker grinding. This prevents immediate setting by slowing down the hydration of C₃A.

Importance of Setting Time

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss why controlling the setting time is crucial in cement hydration. Why do you think we need it?

To make sure masons have enough time to work on the concrete?

Yes! If the cement sets too quickly, it doesn't allow for proper placement. Additionally, it ensures adequate bonding and prevents cracking.

So, how does adding gypsum help in preventing cracking?

When gypsum controls the setting time, it allows for a gradual stiffness build-up, preventing stresses that lead to cracks. Let’s remember this as the 'workability factor'—making concrete work well for the application.

Can you give us an example of where this is important?

Certainly! In large structures like bridges, controlling the setting time is critical to ensure that the entire structure is uniformly hardened without unexpected weaknesses caused by rapid setting.

Perfect, can we summarize again?

Sure! Controlling the setting time is essential for workability, bonding, and preventing cracking, with gypsum playing a pivotal role in this process.

Practical Application of Gypsum in Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's explore how gypsum is used in different types of cement. What types do you know?

I know about Ordinary Portland Cement!

Correct! Gypsum is primarily used in OPC. In what other types might we use it?

Do blended cements use gypsum too?

Absolutely! Blended cements may incorporate gypsum to manage hydration reactions, especially when combined with materials like fly ash or slag. The right amount helps retain the properties we require from cement.

How consistent is the percentage of gypsum added across different cement types?

Good question! While 3-5% is typical, it can vary slightly depending on the specific requirements of the cement type and its intended use.

Can we summarize the practical applications?

Certainly! Gypsum is crucial in OPC and blended cements, controlling hydration and ensuring uniform performance across various cement types.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In cement production, gypsum plays a crucial role by delaying the hydration of tricalcium aluminate (C₃A), preventing rapid setting and allowing for better workability during application. Typically, 3-5% gypsum is blended with clinker during grinding.

Detailed

Role of Gypsum in Cement

Gypsum (CaSO₄·2H₂O) is an essential component in the production of cement, particularly in controlling the setting time of cement when water is added. Without gypsum, cement would set almost instantly, leading to poor workability and limiting the construction process. By delaying the hydration of tricalcium aluminate (C₃A), gypsum moderates the setting process, allowing workers to place and finish concrete effectively. Typically, about 3-5% gypsum is added during the final grinding stage of clinker production. This regulation is vital to ensure that the cement can achieve its desired strength and performance while preventing issues like cracking or inadequate bond strength due to rapid solidification.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

The Importance of Gypsum in Cement

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Without gypsum, cement would set almost immediately upon adding water.

Detailed Explanation

Gypsum is crucial in the cement production process because it prevents the cement from hardening too quickly. If gypsum were not added, the cement would begin to set right away after mixing with water, which would make it challenging to work with during construction. This rapid setting would not allow enough time for pouring and shaping, leading to poor outcomes in construction projects.

Examples & Analogies

Think of making a cake. If you pour the batter into the pan and it starts baking instantly, you won’t be able to pour it into the pan in time, and the cake would end up uneven. Gypsum acts like a timer, giving you the time you need to properly mix and place the cement, similar to how you would time your cake preparation.

How Gypsum Functions as a Retarder

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Gypsum acts as a retarder:

- It delays the hydration of C₃A, controlling the setting time.

Detailed Explanation

Gypsum’s primary role in cement is to delay the hydration of a chemical compound called tricalcium aluminate (C₃A). C₃A is known to react quickly with water, causing cement to harden rapidly. By adding gypsum, the setting time is extended, allowing for better workability. This control over the setting time is essential in large construction projects, where crews need time to finish their work before the material sets.

Examples & Analogies

Imagine you are playing with clay. If the clay dries too quickly, you cannot mold it into the shape you want. Adding water to the clay gives you a bit more time to shape it before it hardens. Gypsum provides that extra time for cement to remain workable before it solidifies, similar to how water helps clay remain soft longer.

Proportion of Gypsum in Cement Production

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Typically, 3–5% gypsum is added during grinding.

Detailed Explanation

In cement production, a specific amount of gypsum, usually between 3 to 5 percent of the total weight, is added during the grinding process of clinker. This precise measurement ensures that the cement has the right equilibrium between workability and strength development. Too little gypsum may lead to rapid setting, while too much could hinder the cement’s ability to gain strength over time.

Examples & Analogies

When baking, adding just the right amount of sugar impacts the sweetness and texture of the cake. Too little makes the cake bland, while too much could make it overly sweet and affect how it rises. Similarly, the 3 to 5 percent of gypsum is like the sugar in cement production, ensuring optimal performance.

Key Concepts

-

Role of Gypsum: Gypsum is crucial for controlling cement setting time.

-

Setting Time: Gypsum acts as a retarder, allowing proper workability during mixing.

-

C₃A Hydration: Gypsum moderates the rapid hydration of tricalcium aluminate to prevent instant setting.

Examples & Applications

Example 1: In bridge construction, using gypsum helps ensure that the concrete sets reliably without unexpected cracking.

Example 2: In blended cements, gypsum maintains control over hydration when mixed with supplementary materials.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Gypsum in the mix, not a quick fix, delays the time, making setting fine.

Stories

Imagine a busy construction site where everyone is rushing. Without gypsum, cement sets too fast and chaos ensues as workers can't finish their tasks. But with gypsum, they have just enough time to ensure everything is perfect.

Memory Tools

GREAT (Gypsum Retards Early-Age Time) helps us remember the purpose of gypsum in cement.

Acronyms

GYP (Gypsum= Yields Perfect setting) reinforces how gypsum helps in achieving proper setting time.

Flash Cards

Glossary

- Gypsum

A mineral composed of calcium sulfate dihydrate (CaSO₄·2H₂O) used to regulate setting time in cement.

- C₃A

Tricalcium aluminate, a major compound in cement that reacts quickly with water.

- Retarder

A substance that slows down the setting time of cement.

Reference links

Supplementary resources to enhance your learning experience.