Chemical Composition of OPC

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to OPC Composition

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to learn about the chemical composition of Ordinary Portland Cement, or OPC. Can anyone tell me what materials are essential in cement production?

Is it limestone and clay?

Correct! Limestone primarily provides lime, which makes up about 60–67% of OPC. This high content of lime helps give cement its strength. Let's memorize this: L for Lime—60–67 percent!

What about silica? How much of it is in OPC?

Good question, Student_2! Silica typically ranges from 17 to 25%. It plays a crucial role in the binding properties of cement. Remember this as 'S for Silica—17 to 25 percent.'

Detailed Components of OPC

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's dive deeper. Who can tell me what alumina contributes to OPC?

Isn't it to help with strength characteristics and temperature resistance?

Exactly! Alumina makes up about 3–8% of OPC. You can remember it as 'A for Alumina—3 to 8 percent.' Iron oxide is next, contributing 0.5-6% and impacting the color of the cement. Let's note that as 'I for Iron—0.5 to 6 percent.'

What role does magnesia play in cement?

Magnesia, ranging from 0.1 to 4%, helps control the setting time. Let's recall: 'M for Magnesia—0.1 to 4 percent.'

Other Important Oxides

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s not forget about sulphur trioxide and alkalis. Who can recall their functions?

Sulphur trioxide helps regulate the setting time, right?

Correct! It usually makes up about 1–3% of OPC. We can remember: 'S for Sulphur—1 to 3 percent.' And alkalis, which include sodium and potassium, are found in small amounts, about 0.2 to 1.3%. Their role is to prevent reactions that could damage concrete. That's 'A for Alkalis—0.2 to 1.3 percent.'

Why is it important to know these percentages?

Knowing these percentages is critical for cement production, as they affect the final properties and reliability of concrete.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The chemical composition of Ordinary Portland Cement (OPC) is vital for understanding its properties and behavior in construction. This section details the main oxides present in OPC, including lime, silica, alumina, iron oxide, magnesia, sulphur trioxide, and alkalis, along with their approximate percentage ranges.

Detailed

Chemical Composition of OPC

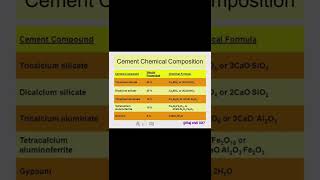

Ordinary Portland Cement (OPC) is primarily composed of various oxides that significantly influence its performance and strength characteristics. The main oxides and their approximate percentage composition in OPC include:

- Lime (CaO): 60–67% - This is the primary component providing cement with its strength.

- Silica (SiO₂): 17–25% - Silica contributes to the binding properties of cement and is crucial for the formation of silicates during hydration.

- Alumina (Al₂O₃): 3–8% - Alumina helps with the formation of cement phases that influence strength characteristics and temperature resistance.

- Iron Oxide (Fe₂O₃): 0.5–6% - Iron oxide affects the color of the cement and its hardness.

- Magnesia (MgO): 0.1–4% - Magnesia’s function is primarily related to controlling the setting time of cement.

- Sulphur Trioxide (SO₃): 1–3% - It is essential for managing the sulfates in cement, which help regulate the setting time.

- Alkalis (Na₂O, K₂O): 0.2–1.3% - These compounds can impact durability but must be controlled to prevent alkali-silica reaction in concrete.

Understanding these chemical compositions is critical for ensuring the consistent production of cement with desired characteristics, thus enabling engineers and builders to achieve reliable and durable construction outcomes.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Chemical Composition

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Cement primarily consists of the following oxides:

Detailed Explanation

Cement is made up of several key chemical oxides that are essential for its properties. These oxides, which include lime, silica, alumina, iron oxide, magnesia, sulphur trioxide, and alkalis, contribute to the performance and characteristics of the cement once it is mixed and cured.

Examples & Analogies

Think of the chemical composition of cement like a recipe for a cake. Each ingredient plays a crucial role—just as flour gives structure and eggs provide moisture, the different oxides in cement ensure that it sets properly, gains strength, and lasts over time.

Lime (CaO)

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Approximate % in OPC: 60–67%

Detailed Explanation

Lime is the most significant component in Ordinary Portland Cement (OPC), making up about 60-67% of its chemical composition. It is critical for developing strength in cement through hydration reactions. When lime reacts with water, it forms calcium silicate hydrate, which is responsible for the cement's strength.

Examples & Analogies

Imagine lime as the foundation of a building. Just like a strong foundation supports the entire structure, lime provides the necessary strength and stability for cement.

Silica (SiO₂)

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Approximate % in OPC: 17–25%

Detailed Explanation

Silica is the second most important oxide in cement, constituting about 17-25% of its composition. It plays a vital role in the formation of calcium silicates, which contribute to the strength and durability of concrete. Silica reacts with lime at high temperatures to produce compounds that increase the resilience of concrete over time.

Examples & Analogies

You can think of silica as a quality control agent in our cake recipe. Just like how the right amounts of certain flavors enhance the overall taste, silica ensures the durability and long-term performance of cement.

Alumina (Al₂O₃)

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Approximate % in OPC: 3–8%

Detailed Explanation

Alumina, making up about 3-8% of OPC, influences the setting times and workability of cement. It helps in the formation of tricalcium aluminate, which reacts quickly with water and is significant in early hydration processes.

Examples & Analogies

Alumina is similar to the sugar in our cake recipe—it helps with flavor and affects how quickly the cake rises. While it doesn’t provide structural integrity by itself, it significantly influences the overall performance of the cement.

Iron Oxide (Fe₂O₃)

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Approximate % in OPC: 0.5–6%

Detailed Explanation

Iron oxide adds to the color of cement and may slightly influence its strength. Its content, which ranges from 0.5 to 6%, also helps in the formation of some of the chemical compounds during the kiln burning process, affecting the characteristics of the cement.

Examples & Analogies

Think of iron oxide as the food coloring in your cake. While it doesn’t significantly change the cake’s structure, it does alter its appearance, which in this case translates to the color and some properties of the cement.

Magnesia (MgO), Sulphur Trioxide (SO₃), and Alkalis (Na₂O, K₂O)

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Approximate % in OPC:

- Magnesia: 0.1–4%

- Sulphur Trioxide: 1–3%

- Alkalis: 0.2–1.3%

Detailed Explanation

Magnesia, sulphur trioxide, and alkalis, although in smaller amounts, also play essential roles in cement performance. Magnesia can affect the strength and setting times, while sulphur trioxide helps stabilize the cement's composition and alkalis can influence the durability of concrete.

Examples & Analogies

These components are like the salt and optional spices in our cake recipe—used in small amounts, they can significantly enhance the final product's flavor and performance, adding to the unique properties of cement.

Key Concepts

-

Lime (CaO): The primary component that gives OPC its strength, making up 60–67%.

-

Silica (SiO₂): Contributes to the binding properties of cement, present at 17–25%.

-

Alumina (Al₂O₃): Helps with strength characteristics and makes up 3–8%.

-

Iron Oxide (Fe₂O₃): Affects cement color, included at 0.5–6%.

-

Magnesia (MgO): Controls setting time, comprising 0.1–4%.

-

Sulphur Trioxide (SO₃): Manages setting time, comprising 1–3%.

-

Alkalis (Na₂O, K₂O): Impact durability at 0.2–1.3%.

Examples & Applications

In a typical bag of OPC, out of 100 kg, approximately 60–67 kg will be lime, which plays a vital role in ensuring the strength of the cement.

When mixing various concrete formulations, understanding that silica comprises 17–25% can help engineers select the appropriate materials for desired performance.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Lime and silica, a strong cement mix, alumina adds strength, making it fix.

Stories

Once upon a time, in a cement factory, Lime was the strongest hero at 60–67%. Silica, the wise one at 17–25%, provided wisdom, while Alumina helped with 3–8% strength as they faced challenges together. Iron Oxide joined the team for color with 0.5–6% support, and Magnesia, the speedy one at 0.1–4%, kept them on time. Together they faced Sulphur Trioxide at 1–3%, and Alkalis at 0.2–1.3% helped maintain stability. In this chemical world, each component played its role perfectly.

Memory Tools

Remember: 'Lemons Sometimes Affect Interesting Money Supplies.' (Lime, Silica, Alumina, Iron Oxide, Magnesia, Sulphur, Alkalis)

Acronyms

The mnemonic 'LSALMSA' can help memorize the oxides

for Lime

for Silica

for Alumina

for Iron Oxide

for Magnesia

for Sulphur

for Alkalis.

Flash Cards

Glossary

- Lime (CaO)

A primary component of cement that provides strength, making up 60–67% of OPC.

- Silica (SiO₂)

An oxide that contributes to the binding properties of cement, making up 17–25% of OPC.

- Alumina (Al₂O₃)

An oxide that helps with the strength characteristics of cement, composing 3–8% of OPC.

- Iron Oxide (Fe₂O₃)

An oxide that affects the color of cement, included at 0.5–6% in OPC.

- Magnesia (MgO)

An oxide that helps control the setting time, comprising 0.1–4% of OPC.

- Sulphur Trioxide (SO₃)

An oxide essential for managing setting time in cement, present at 1–3% in OPC.

- Alkalis (Na₂O, K₂O)

Compounds that can impact durability, making up 0.2–1.3% of OPC.

Reference links

Supplementary resources to enhance your learning experience.