Heat of Hydration

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Heat of Hydration

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to explore the heat of hydration. Can anyone tell me what happens when cement is mixed with water?

The cement hydrates and starts to harden, right?

Exactly! This process is not just about hardening; it involves exothermic reactions, which means heat is released. Let’s take a deeper look: C₃S reacts with water to form Calcium Silicate Hydrate and Ca(OH)₂ along with generating heat.

Why is that heat important?

Great question! The heat generated can affect the concrete’s properties, especially in large structures. If it gets too hot too quickly, it can lead to cracking. So, managing this heat is crucial.

Are there different reactions based on the type of cement?

Yes, different compounds in the cement behave differently. For instance, C₂S generates less heat than C₃S during hydration. This knowledge helps engineers make informed decisions when designing concrete structures.

In summary, the heat of hydration is significant because it can impact the structural integrity of concrete, especially in large constructions.

Challenges with Heat of Hydration

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand what heat of hydration is, let's discuss the challenges it presents.

What kind of challenges are we talking about?

A significant challenge arises from thermal stress. When the temperature of the concrete rises rapidly, it can cause the material to crack. This is especially critical in massive structures like dams.

So, how do we prevent that?

Engineers employ various methods, including using materials that have a lower heat of hydration or adding water to keep the temperature down. It’s all about ensuring a balanced hydration process.

Is there a specific temperature we should aim for?

While there's no one-size-fits-all temperature, maintaining moderate hydration rates generally reduces thermal stresses. Engineers continuously monitor temperatures in massive pours.

In conclusion, managing heat of hydration is essential to avoid cracks in concrete structures.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section discusses the heat of hydration, an important phenomenon where exothermic chemical reactions between cement and water release heat. Such heat generation plays a significant role in concrete applications, especially in large structures where thermal fluctuations can lead to cracking.

Detailed

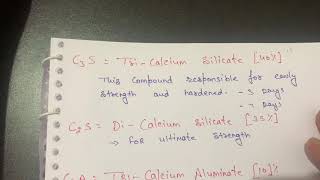

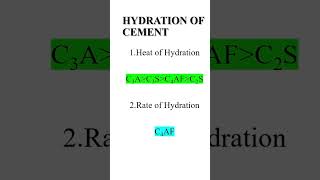

Heat of Hydration

The heat of hydration is a vital aspect of cement chemistry that occurs when cement reacts with water. It involves exothermic chemical reactions, primarily the hydration of key compounds in cement such as Tricalcium Silicate (C₃S) and Dicalcium Silicate (C₂S). These reactions are represented by the following equations:

- C₃S + H₂O → C-S-H (Calcium Silicate Hydrate) + Ca(OH)₂ + heat

- C₂S + H₂O → C-S-H + Ca(OH)₂ (less heat than C₃S)

- C₃A + gypsum + H₂O → Ettringite (expansive)

The heat generated during these reactions is significant, especially in massive concrete structures like dams or bridges. The rise in temperature can lead to thermal stresses and potentially cause cracking if not properly managed. Moreover, controlling the heat of hydration is crucial in ensuring the longevity and integrity of the concrete structure.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Heat of Hydration

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When cement is mixed with water, exothermic chemical reactions occur. This is called heat of hydration.

Detailed Explanation

Heat of hydration refers to the heat generated when cement reacts with water. This process is categorized as exothermic, meaning it releases heat. Whenever cement comes in contact with water, particularly during the mixing phase, it undergoes specific chemical reactions that produce not only solid materials but also heat, which is essential to consider, especially in large constructions.

Examples & Analogies

Think of heat of hydration like brewing tea. When you add hot water to the tea leaves, a reaction occurs that releases flavors and warmth. Similarly, when cement meets water, it reacts, generating heat as it starts to bond and set.

Key Reactions Involved

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Key Reactions:

- C₃S + H₂O → C-S-H (Calcium Silicate Hydrate) + Ca(OH)₂ + heat

- C₂S + H₂O → C-S-H + Ca(OH)₂ (less heat than C₃S)

- C₃A + gypsum + H₂O → Ettringite (expansive)

Detailed Explanation

The heat of hydration involves several key chemical reactions:

- The first reaction is between Tricalcium Silicate (C₃S) and water, which produces Calcium Silicate Hydrate (C-S-H), calcium hydroxide (Ca(OH)₂), and heat. This reaction is quite exothermic and is responsible for a significant amount of heat generation.

- The second reaction involves Dicalcium Silicate (C₂S), which also reacts with water to create C-S-H and Ca(OH)₂ but generates less heat compared to C₃S.

- The third important reaction involves Tricalcium Aluminate (C₃A) combined with gypsum and water to form Ettringite, a crystalline compound that can expand in volume, which plays a role in the setting process.

Examples & Analogies

Imagine baking a cake. The ingredients (flour, sugar, eggs, and baking powder) mix together to create a batter, which then transforms into a fluffy cake in the oven as it heats. Each component (like C₃S, C₂S, and C₃A) plays a vital role in the chemistry of cement, just as the ingredients do in baking, resulting in heat and a final hardened product.

Importance of Heat of Hydration

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The heat generated is critical in massive concrete structures like dams, where temperature rise may cause cracks.

Detailed Explanation

In large concrete structures such as dams, the heat generated during hydration can lead to significant temperature rises within the concrete. This increase in temperature is crucial to monitor because if the temperature rises too much too quickly, it can create internal stresses in the concrete, leading to cracking or even structural failure. Therefore, managing and understanding the heat of hydration is vital for ensuring the integrity and durability of large-scale concrete constructions.

Examples & Analogies

Consider a large pot of water boiling on the stove. If the water heats up too quickly or unevenly, it can splash or even crack the pot. Similarly, if large pours of concrete heat too quickly, it can crack the structure. Engineers thus need to monitor this process closely, just like you would watch your pot to prevent boiling over.

Key Concepts

-

Exothermic Reactions: Reactions that release heat, occurring when cement and water mix.

-

Role of C₃S: This compound contributes significantly to early strength and generates a large amount of heat during hydration.

-

Thermal Management: Controlling the heat produced during hydration is crucial to prevent cracking.

Examples & Applications

In large dam constructions, managing the heat of hydration is critical to prevent structural failure caused by thermal cracking.

Adding water or using low-heat cement can help manage the temperature during large concrete pours.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When cement meets water, watch it heat, to bond it strong and make it neat.

Stories

Imagine a giant pot of cement soup boiling over—engineers must carefully monitor its temperature to keep it from cracking, ensuring their building stands tall and strong.

Memory Tools

Heat + C₃S = Strong! HCS for Hydration, C₃S for early strength!

Acronyms

COLD

Control Over Load during hydration. Managing temperature reduces cracking risk!

Flash Cards

Glossary

- Heat of Hydration

The heat generated during the exothermic chemical reactions when cement reacts with water.

- C₃S

Tricalcium silicate, a primary compound in cement known for its ability to provide early strength.

- CSH

Calcium silicate hydrate, the main product of hydration that contributes to concrete's strength.

- Thermal Stress

Stress induced in materials due to changes in temperature.

Reference links

Supplementary resources to enhance your learning experience.