Indian Standards Related to Cement

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Indian Standards for Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to discuss the Indian Standards related to cement. Why do you all think such standards are important in the industry?

I think they ensure that the cement produced is safe to use.

And they probably help in maintaining consistency in quality!

Absolutely! The Bureau of Indian Standards, or BIS, sets these specifications to ensure quality and uniformity in production.

What are some specific standards that we follow?

Great question! For instance, IS 269, IS 8112, and IS 12269 are specific grades of Ordinary Portland Cement.

What do these IS codes actually cover?

They cover parameters like fineness, compressive strength, setting time, and more, which ensures only the best quality cement reaches the market.

In summary, the BIS helps ensure that the cement we use is reliable, strong, and safe for construction.

Key IS Codes Explained

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about some specific IS codes. Can anyone tell me the importance of IS 4032?

Is that the one related to the chemical analysis of hydraulic cement?

Exactly! It ensures that we analyze the chemical composition accurately to maintain quality.

What about IS 4031?

Great point! IS 4031 provides methods of physical tests, which are vital to assessing the performance parameters of cement.

How does fineness affect cement quality?

Good question! Fineness, as specified in IS codes, affects hydration rates and, consequently, the strength of the cement.

In conclusion, these standards provide a comprehensive framework to ensure that cement quality meets safety and performance requirements.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section details significant IS codes and the parameters they cover, such as fineness, compressive strength, setting time, soundness limits, and chemical composition limits that ensure quality and uniformity in cement production.

Detailed

Indian Standards Related to Cement

To ensure the quality and uniformity of cement, standards set by the Bureau of Indian Standards (BIS) govern various aspects of cement production and testing in India. Some key IS codes include:

- IS 269: Ordinary Portland Cement, 33 Grade

- IS 8112: Ordinary Portland Cement, 43 Grade

- IS 12269: Ordinary Portland Cement, 53 Grade

- IS 1489 (Part 1 & 2): Portland Pozzolana Cement (fly ash-based and calcined clay-based)

- IS 455: Portland Slag Cement

- IS 3812: Fly Ash for use in cement and concrete

- IS 4031 (Parts 1 to 15): Methods of physical tests for hydraulic cement

- IS 4032: Methods of chemical analysis of hydraulic cement

- IS 650: Standard sand for testing cement

- IS 8042: White Portland Cement

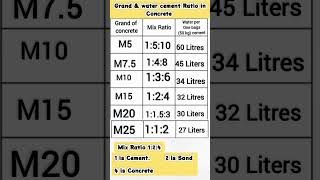

These standards specify important parameters, including:

- Fineness (specific surface area)

- Compressive strength requirements

- Setting time ranges

- Soundness limits

- Chemical composition limits (e.g., MgO < 6%, SO₃ < 3%)

This rigorous framework ensures that the cement produced complies with safety and engineering requirements.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Cement Standards

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

To ensure quality and uniformity, cement production and testing are governed by Bureau of Indian Standards (BIS) specifications. The key IS codes include:

Detailed Explanation

The Bureau of Indian Standards (BIS) oversees the quality and uniformity of cement used in construction in India. They have established specific standards, referred to as IS codes, which set the guidelines for the production and testing of various types of cement.

Examples & Analogies

Think of BIS codes as the rulebook in a sports game. Just as players must follow the rules to ensure fair play, cement manufacturers must adhere to these standards to assure that the cement is safe and reliable for construction.

Key IS Codes for Cement

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

IS 269 Ordinary Portland Cement, 33 Grade

IS 8112 Ordinary Portland Cement, 43 Grade

IS 12269 Ordinary Portland Cement, 53 Grade

IS 1489 (Part 1 & 2) Portland Pozzolana Cement (fly ash-based and calcined clay-based)

IS 455 Portland Slag Cement

IS 3812 Fly Ash for use in cement and concrete

IS 4031 (Parts 1 to 15) Methods of physical tests for hydraulic cement

IS 4032 Methods of chemical analysis of hydraulic cement

IS 650 Standard sand for testing of cement

IS 8042 White Portland Cement

Detailed Explanation

The key IS codes related to cement detail specific types of cements and the methods of testing them. For instance, IS 269 refers to Ordinary Portland Cement of 33 Grade, while IS 8112 and IS 12269 refer to 43 Grade and 53 Grade cement, respectively. Other standards outline specific types like Portland Pozzolana Cement or Portland Slag Cement, and testing methods for assessing physical and chemical properties.

Examples & Analogies

Just as different recipes exist for different types of cakes (like chocolate cake vs. vanilla cake), these IS codes provide the 'recipes' for producing various types of cement, ensuring that each type is made with the right materials and processes for its intended use.

Key Specifications Within the Standards

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

These standards specify:

- Fineness (specific surface area)

- Compressive strength requirements

- Setting time ranges

- Soundness limits

- Chemical composition limits (e.g., MgO < 6%, SO₃ < 3%)

Detailed Explanation

The IS standards not only define the types of cement but also specify critical performance parameters. Factors like fineness, which measures how finely the cement is ground, affect its hydration speed and strength. Compressive strength requirements ensure the cement can withstand loads. Setting time ranges dictate how long the cement remains workable, while soundness limits prevent excessive expansion post-setting. Chemical composition limits ensure harmful compounds are minimized.

Examples & Analogies

Imagine baking a cake: if you use too much sugar or baking powder, the cake might not rise or might taste too sweet. In cement standards, ensuring the right chemical composition and physical properties is vital for the 'cake' to perform well in construction, just like a well-balanced cake needs the right ingredients to be enjoyable.

Key Concepts

-

Indian Standards: Regulatory framework for cement production and quality testing in India.

-

IS Codes: Specific standards set by BIS that govern different aspects of cement, ensuring industry compliance.

-

Quality Assurance: Importance of uniformity and quality control in cement to meet safety standards.

Examples & Applications

IS 269 specifies the requirements for Ordinary Portland Cement of 33 Grade, ensuring it meets the necessary standards for specific applications.

IS 8112 for 43 Grade cement ensures higher strength for structures requiring more durability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When building tall and wide, ensure standards abide, BIS on your side, safety and quality coincide.

Stories

Imagine a builder who rushed his work without checking the BIS standards. The first storm revealed cracks, teaching him the value of standards and preventing collapses.

Memory Tools

Remember the acronym F-C-S (Fineness, Compressive Strength, Setting time) to recall key parameters in standards.

Acronyms

BIS - 'Building Integrity Standards' to remind you of the importance of safety and quality in cement.

Flash Cards

Glossary

- Bureau of Indian Standards (BIS)

The national standards body of India responsible for the formulation and management of standards for various products, including cement.

- IS Code

A standard issued by the Bureau of Indian Standards that specifies guidelines for the production, testing, and quality of a product.

- Fineness

The measure of the particle size of cement, impacting its hydration rate and strength.

- Compressive Strength

The capacity of a material or structure to withstand axial loads without failure.

- Setting Time

The time taken for cement to harden after it is mixed with water.

- Soundness

The ability of the cement to maintain its volume and not undergo expansion or contraction after setting.

Reference links

Supplementary resources to enhance your learning experience.