Cooling of Clinker

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Clinker Cooling

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore the cooling process of clinker. Why do you think this step is necessary after the clinker has been formed?

To make sure it doesn't get too hot and break down?

Good point! Cooling is crucial as it preserves the mineral structures formed during the high temperatures in the rotary kiln. Can anyone name one mineral we want to preserve?

C₃S, right? It's important for the strength of cement.

Exactly! C₃S is vital for providing early strength to the cement. So, cooling helps maintain its properties.

How do we cool it down?

Great question! We use air in grate coolers for rapid cooling. This method is efficient and effective.

Can slow cooling affect the cement?

Indeed, slow cooling can lead to undesirable changes in structure and reduce performance. In summary, rapid cooling preserves the desired mineral forms, which is critical for producing quality cement.

Mechanics of Grate Coolers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s delve into how grate coolers work. Who can explain how air is utilized in this process?

Isn't it driven through the clinker to cool it down quickly?

Exactly! The hot clinker is spread over a grate, and air is blown through it. This method ensures efficient heat exchange. Why do you think rapid cooling is better than slow?

It probably helps maintain clinker strength, right?

Correct! Keeping the mineral forms intact by cooling quickly helps the cement meet quality standards.

So, what happens if the coolers fail?

This could result in overheating, which may alter mineral structures negatively. Remember, preserving mineral composition is key!

Summarizing, rapid cooling maintains the essential properties necessary for quality cement production.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we discuss the importance of cooling clinker rapidly post-formation in rotary kilns. It primarily utilizes air in grate coolers to cool the clinker efficiently, which helps in retaining the desired mineral compositions and improving the performance characteristics of the cement.

Detailed

Cooling of Clinker

The process of cooling clinker is vital in cement manufacturing as it significantly affects the final product's properties and quality. After the formation of clinker in rotary kilns, the hot clinker is subjected to rapid cooling using air in grate coolers. This quick cooling method is essential as it preserves the desired mineral forms that contribute positively to the strength and durability of the cement.

Moreover, maintaining the proper cooling rate can lead to better reactability during subsequent grinding and hydration processes. By ensuring that the clinker maintains its chemical structure, it aids in producing cement that exhibits optimal performance in construction applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Cooling Process

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Hot clinker is cooled rapidly using air in grate coolers.

Detailed Explanation

The cooling process of clinker is crucial in cement manufacturing. Once the clinker is formed in the rotary kiln, it is very hot and needs to be cooled promptly. This rapid cooling is typically achieved using air in a device known as a grate cooler. The air passes through the hot clinker, effectively reducing its temperature. The purpose of this rapid cooling is to ensure that the desired mineral forms in the clinker are preserved, which is vital for the strength and quality of the final cement product.

Examples & Analogies

Imagine baking a cake in an oven. If you take the cake out and let it sit at room temperature, it might lose its fluffiness. However, if you immediately place it in a cooling fan or on a wire rack, it retains its structure. Similarly, cooling clinker quickly helps maintain its beneficial properties for cement production.

Importance of Rapid Cooling

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Rapid cooling preserves the desired mineral forms.

Detailed Explanation

The mineral composition of clinker is vital for creating high-quality cement. During the heating process in the rotary kiln, various chemical reactions occur, forming different compounds. If these clinkers are not cooled quickly, they might undergo further transformations, leading to the formation of undesired minerals. By cooling the clinker rapidly, manufacturers ensure that specific compounds, such as alite (C₃S) and belite (C₂S), remain intact. These compounds are essential for the strength and durability of the cement.

Examples & Analogies

Think of making ice cream. If you want a creamy texture, you have to cool it quickly — otherwise, larger ice crystals will form, ruining the smoothness. Similarly, in cement production, quick cooling results in a better-quality product by preserving the right mineral structures.

Key Concepts

-

Rapid Cooling: This process is essential to maintain the desired mineral forms in clinker, impacting cement performance.

-

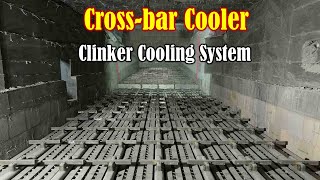

Grate Coolers: A mechanism that effectively cools clinker using forced air, crucial for the preservation of its mineral composition.

-

Mineral Composition: Refers to the specific minerals in clinker that contribute to the cement's strength and durability.

Examples & Applications

In the production of Ordinary Portland Cement (OPC), rapid cooling of clinker is vital to keep compounds like C₃S intact, ensuring early strength is achieved.

If clinker is cooled too slowly, it may result in the formation of undesirable phases that compromise the strength of the final cement product.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cool the clinker, that's the trick, Keep its structure strong and thick!

Stories

Imagine a superhero named Clinker, who needs a cool breeze to stay powerful and maintain his strength to build towering structures!

Memory Tools

CRISP - C for Cooling, R for Rapid, I for Integrity of structure, S for Strength, P for Preservation of minerals.

Acronyms

CAG - Clinker, Air Coolers, Grate; to remember the cooling method for clinker.

Flash Cards

Glossary

- Clinker

The intermediate product in cement manufacturing formed during sintering, mainly comprising calcium silicates.

- Grate Coolers

Cooling equipment that uses forced air to rapidly cool hot clinker post-formation.

- Mineral Composition

The specific arrangement and type of minerals present in clinker important for cement quality.

- Preservation

The maintenance of the original mineral structures during cooling to ensure optimal cement properties.

Reference links

Supplementary resources to enhance your learning experience.