Coefficient of Discharge

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Coefficient of Discharge

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

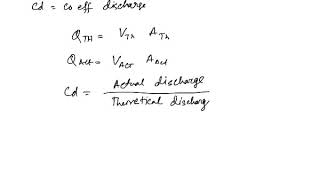

Welcome everyone! Today, we are going to dive into the concept of the coefficient of discharge, denoted as C_d. This significant parameter is used in fluid mechanics to measure the ratio of actual discharge to theoretical discharge through orifice meters and venturimeters.

Why do we even need to measure the coefficient of discharge?

Great question! We measure the coefficient of discharge to account for real-world factors that cause flow losses. In ideal conditions, Bernoulli's equation provides a theoretical discharge, but practical scenarios involve losses due to friction, turbulence, and other factors.

How do we calculate the coefficient of discharge?

The coefficient of discharge can be calculated using the formula: C_d = Q_actual / Q_theoretical. The 'Q_actual' is the measured flow rate, while 'Q_theoretical' is calculated using Bernoulli's equation. Remember, a C_d value less than 1 indicates that there are losses!

What would a C_d of 1 mean?

If C_d equals 1, it means the actual discharge matches the theoretical discharge — this is ideal and often unachievable in real scenarios. Energy losses never entirely go away in real flows.

Can you give us an example?

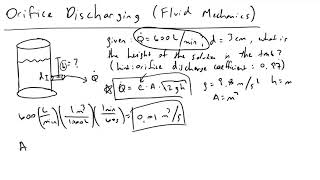

Absolutely! Consider an orifice meter in a pipe. If the theoretical discharge calculated using Bernoulli's equation is 10 m³/s but your actual measured discharge is 8 m³/s, then your C_d would be 0.8, indicating 20% energy loss.

To summarize, the coefficient of discharge quantifies how much energy is lost in real fluid flows through measuring devices. It's essential for accurate analysis and design in fluid systems.

Understanding Energy Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

As we explore further, let's talk about energy losses. Why do we have these losses when fluid flows through orifice meters?

Isn't it just because of friction?

That's correct! Friction is one cause, but there are also losses from turbulence, sudden changes in flow area, and other factors. Each of these contributes to the actual discharge being less than the theoretical discharge.

So what do we do about these losses?

We can calculate the coefficient of discharge to better understand these losses. Moreover, we often introduce kinetic energy correction factors when the velocity distribution isn't uniform, especially in turbulent flows.

How do we apply these correction factors?

You apply the kinetic energy correction factor to the average velocity to determine the total kinetic energy of the flow considering the non-uniform distribution. This factor helps refine your calculations for discharge.

What are typical values for these correction factors?

For fully developed laminar flow, it's typically around 2, while for turbulent flow, it ranges from 1.04 to 1.1. These variations highlight how different flow conditions affect energy distribution.

In summary, understanding and calculating energy losses through the coefficient of discharge, along with applying kinetic energy correction factors, is crucial for accurate fluid system design.

Practical Implications of Coefficient of Discharge

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's talk about the practical applications of the coefficient of discharge. Why is it important in engineering?

Does it affect the design of pipelines?

Exactly! Knowing the C_d helps engineers predict how the fluid will move through pipes and other systems. They can design accordingly to minimize losses.

Are there other fields that utilize this concept?

Yes! In fields like environmental engineering, understanding fluid mechanics, including the coefficient of discharge, plays a critical role in predicting how pollutants will disperse in water systems.

What about in automotive design?

Great example! The evolution of car shapes to reduce drag coefficients relates closely to our discussion on discharge coefficients. Improved aerodynamics directly impact fuel efficiency.

Can we see these principles in action in real life?

Absolutely! Many water treatment plants and plumbing systems rely on precise discharge calculations to ensure proper flow rates and effective operation.

To summarize, the coefficient of discharge plays a significant role in various engineering disciplines, from civil to mechanical to environmental engineering, impacting the efficiency of fluid systems.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we explore the concept of the coefficient of discharge (C_d), which accounts for energy losses in fluid flow through measuring devices such as orifice meters and venturimeters. The section further emphasizes the importance of understanding actual versus theoretical discharge and introduces kinetic energy correction factors for non-uniform flow distributions.

Detailed

Coefficient of Discharge

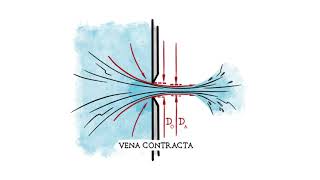

The coefficient of discharge (C_d) is an important measure in fluid mechanics that quantifies the efficiency of flow through devices such as orifice meters and venturimeters. It is defined as the ratio of actual discharge (Q_actual) to the theoretical discharge (Q_theoretical) predicted by Bernoulli’s equation and mass conservation principles. This coefficient incorporates the energy losses occurring due to friction and turbulence as the fluid passes through these measuring devices.

The section examines the differences between the theoretical predictions, which assume ideal, lossless flow, and the actual flow rates observed, which account for various losses including kinetic energy corrections. The section also highlights the roles of static, dynamic, and stagnation pressures in understanding the energy characteristics of fluid flow. In practical scenarios, understanding the coefficient of discharge helps civil and mechanical engineers design more efficient and accurate fluid systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Coefficient of Discharge

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Coefficient of discharge is C here, it is not a coefficient of drag, please do not have a conclusion between the two terms.

Detailed Explanation

The coefficient of discharge (CD) is a crucial concept in fluid mechanics that relates the actual flow of fluid through a device to the theoretical flow predicted by the Bernoulli equation. It is essential to understand that this coefficient is not to be confused with the drag coefficient, which pertains to the resistance faced by an object moving through a fluid. In essence, CD quantifies how much actual flow deviates from theoretical predictions due to factors like energy losses in the system.

Examples & Analogies

Consider a water faucet. When you fully open the faucet, the amount of water flowing out (actual flow) might be less than the amount predicted by calculations assuming no losses (theoretical flow). The coefficient of discharge would represent this difference, helping us understand how effective our faucet design is relative to ideal expectations.

Application of Coefficient of Discharge in Venturi and Orifice Meters

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So, we introduced the coefficient of the discharge, the C value, which is the ratio between actual discharge by theoretical discharge. ... Along with this, energy losses will also affect the flow rates, which necessitates the need for this coefficient.

Detailed Explanation

In practical applications like venturi meters and orifice meters, the coefficient of discharge becomes vital. These devices measure the flow rates of fluids. The theoretical discharge, calculated using Bernoulli's principle, often overestimates the actual discharge due to friction, turbulence, and other losses in the system. Therefore, the coefficient of discharge (CD) is introduced as a correction factor that effectively represents the ratio of actual to theoretical discharge, balancing these discrepancies and providing accurate flow measurements.

Examples & Analogies

Imagine trying to measure how much water flows through a hose using a simple flow rate calculation. If the hose has bends and kinks, the actual water flow will differ from what you calculate using ideal conditions. The coefficient of discharge accounts for these real-world obstacles, making it possible to give a more accurate reading of the water flow.

Importance of Experimental and Analytical Concepts

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So, we need we do not look it very microscopically, how it is changing, but as a gross representation, we just look it the coefficient of discharge as the relationship between the theoretical and the actual.

Detailed Explanation

The coefficient of discharge serves as a bridge between experimental observations and theoretical analyses. It allows engineers and scientists to effectively relate their empirical findings—based on real fluid behavior with their theoretical models, which often assume ideal conditions without losses. By incorporating this coefficient into our calculations, we can achieve greater accuracy in predicting fluid flow behavior in various applications, thus enhancing the design and reliability of fluid systems.

Examples & Analogies

Think of a sports coach analyzing a player's performance using both game footage (experimental data) and training drills (theoretical performance). The coach uses the insights from both perspectives to refine the player's technique and improve their game. Similarly, the coefficient of discharge helps refine theoretical models with insights gathered from practical experiments.

Kinetic Energy Correction Factors

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In situations with non-uniform velocity distributions, we apply kinetic energy correction factors to better estimate the total kinetic energy in the flow.

Detailed Explanation

In fluid dynamics, flow is seldom uniform, particularly in pipes. This non-uniformity means that using average velocities to calculate kinetic energy can lead to inaccuracies. Kinetic energy correction factors are introduced to adjust for this discrepancy, providing a more accurate representation of the actual kinetic energy in the fluid. These factors vary based on the flow type, helping to align theoretical models with real-world conditions.

Examples & Analogies

Consider a crowded highway where some cars are moving faster than others due to traffic conditions. If you only calculate the average speed of the cars to estimate how fast everyone is moving, you might underestimate the actual kinetic energy of the traffic flow. By applying correction factors, like recognizing that some cars are moving significantly quicker, you get a clearer picture of the overall kinetic energy on that highway.

Key Concepts

-

Coefficient of Discharge (C_d): A measure of the efficiency of discharge flow compared to theoretical discharge.

-

Energy Losses: Losses that occur due to friction, turbulence, and flow area changes impacting fluid discharge.

-

Kinetic Energy Correction Factors: Adjustments made to account for non-uniform flow velocity distributions.

Examples & Applications

An orifice meter shows a theoretical discharge of 100 liters/min, but actual measured flow is 80 liters/min. Thus, C_d = 0.8.

In designing a pipeline, understanding the C_d assists engineers to minimize flow losses effectively, ensuring smoother fluid transportation.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When flow is true and C_d is high, Energy's lost won't let us fly.

Stories

Once, a river had two paths: one smooth and one rocky. The smooth path represented ideal flow with no losses (high C_d), while the rocky path illustrated energy losses and struggles (low C_d).

Memory Tools

Remember: C for Coefficient, D for Discharge - Counting how much we lose on charge!

Acronyms

C_d = Q_a / Q_t

Actual over Theoretical

for flow to remain factual.

Flash Cards

Glossary

- Coefficient of Discharge (C_d)

The ratio of the actual discharge to the theoretical discharge through a measuring device, accounting for energy losses.

- Theoretical Discharge (Q_theoretical)

The flow rate predicted by Bernoulli's equation under ideal, lossless conditions.

- Actual Discharge (Q_actual)

The measured flow rate that occurs in real fluid flow situations, affected by various energy losses.

- Kinetic Energy Correction Factor

A factor used to correct the kinetic energy calculations for non-uniform velocity distributions in fluid flow.

- Static Pressure

The pressure exerted by a fluid at rest or in a flowing fluid's non-moving section.

- Dynamic Pressure

The pressure related to the motion of the fluid, calculated using the kinetic energy per volume.

- Stagnation Pressure

The pressure measured when a fluid is brought to a complete stop.

Reference links

Supplementary resources to enhance your learning experience.