Evolution of Drag Coefficient

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Drag Coefficient

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing the drag coefficient, specifically its evolution in automobile design. Let's start by remembering that the drag coefficient, or C<sub>D</sub>, quantifies how aerodynamic a vehicle is. Why do you think this matters in design?

It helps in reducing fuel consumption, right?

Exactly! Lower drag means less fuel is needed for the same speed. Initially, in the early 1900s, the value of C<sub>D</sub> was about 0.8. Anyone know what that means?

It means the car was not very aerodynamically efficient.

Correct! Over time, we've seen this value drop to around 0.15. This represents a significant advancement in vehicle aerodynamics.

Historical Changes in Drag Coefficient

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

In the evolution of car design, reducing the drag coefficient was a primary focus. Can anyone guess how much fuel savings this represents as the coefficient dropped?

If it went from 6 liters to 1 liter for the same distance, that's like a reduction to one-sixth of the fuel!

Precisely! This illustrates why the evolution of fluid mechanics has played a crucial role in the automotive sector.

So, it all connects back to the continued research and experimentation in the field of aerodynamics?

Absolutely, ongoing advancements in understanding airflow around vehicles have led to this remarkable decrease.

Impact of Design on Drag Coefficient

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about design. How do you think vehicle shapes influence the drag coefficient?

More streamlined shapes would likely help reduce drag.

Right! Vehicles are now designed with smoother contours, which minimize air resistance. This strategic design has helped us reach that theoretical minimum of 0.15.

What about the effect of speed? Does it change the drag coefficient?

Good question! While the drag coefficient can be affected by speed, it’s generally considered constant at typical driving conditions, unless the shape of the vehicle changes. Let's keep exploring how this impacts real-world applications!

Real-World Applications of Drag Coefficient in Industry

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

When we look at the contributions of reduced drag in fuel efficiency, how might this knowledge translate into real-world applications?

Manufacturers would focus more on aerodynamic features in their new models.

Absolutely! By optimizing design, manufacturers can produce vehicles that are not only more efficient but also more environmentally friendly due to reduced emissions.

So, it's not just about speed, but also sustainability?

Exactly! The evolution of the drag coefficient reflects broader trends in automotive design focusing on efficiency and sustainability.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The evolution of the drag coefficient is crucial in automotive design, reflecting advancements in fluid mechanics and aerodynamics. From an initial average of 0.8 in the early 20th century, efforts to optimize vehicle shapes have brought this value down to around 0.15 today, resulting in significant improvements in fuel efficiency.

Detailed

Detailed Summary

The evolution of the drag coefficient (CD) over the last 120 years signifies a major achievement in both fluid mechanics and automotive design. Initially, the drag coefficient was approximately 0.8, indicating high resistance to air flow, which resulted in increased fuel consumption. However, due to innovations in car design and a deeper understanding of fluid dynamics, this coefficient has significantly decreased to a theoretical minimum of 0.15.

This shift illustrates the importance of streamlining the shape of vehicles, enhancing their aerodynamic properties. As the drag coefficient approaches 0.15, it concurrently demonstrates the efficiency improvements in fuel consumption — where vehicles that once needed 6 liters of fuel for a certain distance now require just 1 liter, thanks to this reduced drag. The historical context and milestone advancements in vehicle aerodynamics underscore the vital connection between fluid mechanics and automotive engineering.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Drag Coefficient

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

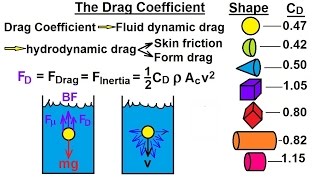

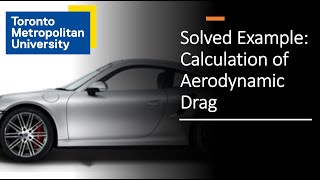

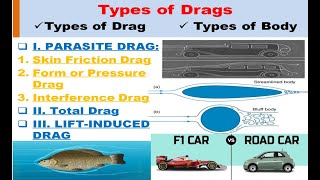

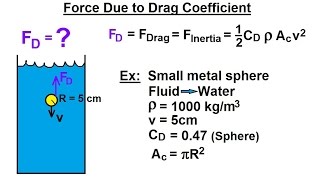

The basic idea is to, because V stands for the design velocities, area is a projected area, which is more or less constant. So, rho is the density of air. Only the C can be changed. Drag Force = 𝜌 * V^2 * A * C_D.

Detailed Explanation

The drag coefficient, denoted as C_D, plays a vital role in fluid dynamics, specifically in quantifying the drag force acting against an object moving through a fluid, in this case, air. The drag force is influenced by several factors: V, the velocity at which the object moves; A, the cross-sectional area of the object; and ρ, the fluid's density. As the other factors are constant, changes in the drag coefficient directly affect the drag force experienced by the object.

Examples & Analogies

Imagine riding a bicycle. If you're riding in a straight line and suddenly you change your posture — sitting upright versus leaning forward — you will experience different drag forces. Leaning forward reduces the area exposed to the wind, thus lowering the drag coefficient and making it easier to maintain speed.

Historical Changes in Drag Coefficient

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Starting from 1800s to 2020, the coefficient of drags, which earlier was close to 0.8, has now reduced to 0.15, very close to the theoretical minimum value.

Detailed Explanation

Over approximately 120 years, the drag coefficient for vehicles has evolved significantly, dropping from about 0.8 to 0.15. This reduction illustrates advancements in aerodynamic design, largely due to research and experiments aimed at identifying the optimal shapes for reducing air resistance. This achievement is crucial for making vehicles more fuel-efficient.

Examples & Analogies

Think of a water slide. A slide that is straight and streamlined allows you to zip down quickly, facing less resistance from the water, while a slide that is curvy and wide may slow you down due to turbulence. Similarly, cars have gone through design changes to streamline shapes, reducing drag and enhancing performance.

Impact of Design on Drag Coefficient

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The shape of cars has changed, leading to modifications in flow patterns as they move with a design velocity.

Detailed Explanation

The evolution of car designs over the years has focused on creating shapes that promote smooth airflow over their surfaces. Enhanced aerodynamics not only affects performance but also fuel consumption, as a lower drag coefficient means less effort is needed to maintain speed. This has led to the theoretical minimum drag coefficient nearing around 0.15 for modern vehicles.

Examples & Analogies

Consider a swimmer: a swimmer who cuts through the water with a streamlined body achieves greater speeds compared to one who splashes around. This is because the streamlined shape helps minimize resistance, akin to how modern car designs reduce aerodynamic drag, promoting efficiency.

Significance of the Evolution

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The evolution from 0.8 to 0.15 in the drag coefficient indicates advancements in automobile design and efficiency.

Detailed Explanation

The significant drop in drag coefficient is not just a number; it represents a collective achievement in automotive engineering, highlighting improved technologies and understanding of fluid mechanics. Such advancements contribute to creating more fuel-efficient vehicles, thereby aiding in both economic and environmental goals.

Examples & Analogies

Consider this evolution like the transition from older, heavier mobile phones to today's sleek smartphones. Just as newer designs optimize functionality and ease of use while minimizing bulk, innovations in car design have optimized speed and fuel efficiency by reducing air resistance.

Key Concepts

-

Drag Coefficient: A measure of aerodynamic drag, influencing fuel efficiency.

-

Streamlining: The process of shape optimization to minimize drag.

-

Fuel Efficiency: The relationship between aerodynamic design and fuel consumption.

-

Historical Impact: The evolution of drag coefficient reflects technological advancements.

Examples & Applications

An automobile designed with a CD of 0.15 uses significantly less fuel compared to one with a CD of 0.8.

In competition racing, cars are designed with low drag coefficients to maximize speed and minimize fuel usage.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Low drag brings cheer, fuel savings are near; streamline the shape, watch efficiency escape!

Stories

Once there was a clunky car who dreamed to go far; as it changed its shape, it cut through like a tape, saving gas as it sped under the radar.

Memory Tools

Remember: D.R.A.G. - Design Responsive Aerodynamics for Growth in efficiency.

Acronyms

C<sub>D</sub> - Cost of Drag

Understanding the relationship between drag and fuel cost.

Flash Cards

Glossary

- Drag Coefficient (C<sub>D</sub>)

A dimensionless number that represents the drag force on an object in a fluid environment, crucial in aerodynamic optimization.

- Streamlining

The design technique aimed at reducing drag by shaping an object to allow smooth flow.

- Aerodynamics

The study of the behavior of air as it interacts with solid objects, critical for understanding vehicle design.

- Theoretical Minimum Value

The lowest possible value of a coefficient that can be achieved under ideal conditions.

Reference links

Supplementary resources to enhance your learning experience.