Venturimeter Functionality

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Venturimeter Functionality

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to learn about the functionality of venturimeters. Does anyone know what a venturimeter does?

Isn't it used to measure the flow rate of a fluid?

That's correct! Venturimeters calculate flow rates by creating a pressure difference in the fluid. Can anyone explain how this pressure difference is generated?

Is it because of the change in the flow area?

Exactly! As fluid flows through the converging section, its velocity increases and pressure decreases. Remember the acronym 'CAV' - Converging Area Velocity.

What happens when it reaches the diverging area?

Great question! The fluid slows down, and the pressure increases again as it exits. That’s a fundamental aspect of how venturimeters work.

Bernoulli's Equation and Venturimeter Calculations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss how to use Bernoulli’s equation in calculating flow rates through venturimeters. What do we need to consider when applying this equation?

We need to think about the kinetic energy correction factors, right?

Absolutely! The kinetic energy correction factor accounts for non-uniform velocity distributions in the flow. Can anyone tell me why this is important?

Because using an average velocity may not give us the accurate kinetic energy of the fluid?

Exactly! For laminar flow, the factor is approximately 2, and for turbulent flow, it can range from 1.04 to 1.11. Remember, 'KewL' - Kinetic Energy with Laminar.

So, how does the coefficient of discharge come into play?

Good point. The coefficient of discharge relates the actual discharge to the theoretical discharge computed using Bernoulli’s equation, establishing an essential relationship in flow measurements.

Practical Applications of Venturimeters

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about where we use venturimeters in real life. Can anybody think of an application?

In industrial settings, right? For measuring the flow of liquids?

Exactly! They are crucial in many industrial processes. A reminder for us is 'EPI' - Essential for Process Industry.

What about in water supply systems? Are venturimeters used there?

Yes! They help monitor water flows in municipal supply systems and ensure efficiency.

How do engineers ensure accuracy with these tools?

Engineers consider all pressure types—static, dynamic, and stagnation pressures—when designing and using venturimeters. A key takeaway: Assess the system comprehensively.

Review and Practice

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ve covered a lot about venturimeter functionality and the Bernoulli equation. Let's review! What are some of the core concepts we discussed?

The pressure differences generated by flow area changes!

Also, the importance of kinetic energy correction factors!

Perfect! How about the coefficient of discharge?

It helps relate actual to theoretical discharge!

Great summary! Remember the acronym 'KAPS' - Key Aspects of Practical Systems. That wraps up our session today!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section explains the operational principles of venturimeters, detailing how they measure fluid flow through converging and diverging zones, and how the Bernoulli equation, with consideration of kinetic energy correction factors, is employed in practical fluid flow problems to calculate discharge while accounting for energy losses.

Detailed

Venturimeter Functionality

Introduction

Venturimeters are essential tools for measuring the flow of fluids in various applications within civil and mechanical engineering. This section elaborates on their working principles, key differences from orifice meters, and the utilization of the Bernoulli equation to solve real-life fluid flow problems.

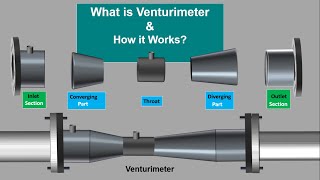

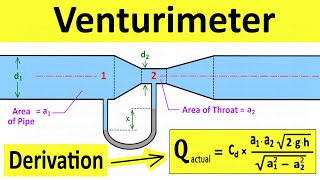

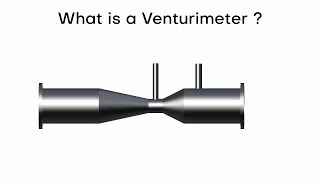

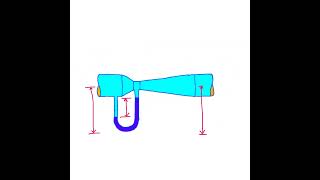

Functionality of Venturimeters

Venturimeters feature converging and diverging zones that allow for a reduction in the cross-sectional area of the flow. This design generates a pressure difference proportional to the flow velocity, enabling the calculation of discharge. In contrast, orifice meters consist of a simple plate with a hole, lacking these zones.

Application of Bernoulli's Equation

When computing the discharge through venturimeters or orifice meters, one must apply the Bernoulli equation. This equation must be adjusted for kinetic energy correction factors due to non-uniform velocity distributions. The coefficient of discharge (C_D) is introduced to account for energy losses, maintaining a relationship between actual and calculated discharge.

Key Considerations

- Kinetic Energy Correction Factors: Critical when analyzing fluid velocities, as average velocities may not accurately represent real-world conditions. For laminar flow, the correction factor is generally around 2, while for turbulent flow, it varies between 1.04 to 1.11.

- Static, Dynamic, and Stagnation Pressures: Understanding these pressure types is crucial in applying Bernoulli's equation effectively in fluid systems.

Conclusion

This section lays the groundwork for understanding how venturimeters function and their practical applications, particularly in determining flow rates and ensuring efficient fluid dynamics in engineering contexts.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Venturimeter

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now come back to this simple experimental setups, we generally do the measuring the flow in a pipe, either in a venturimeter or the orifice meter. The orifice meter is a small device, that means it will be a circle and there is a hole inside this. This is called the orifice. In case of the venturimeter you have a diverging zone and converging zone.

Detailed Explanation

A venturimeter is a device used for measuring the flow rate of a fluid through a pipe. It consists of three sections: a wider section where the fluid enters, a narrow section where the fluid speed increases, and then a wider section again where the fluid exits. The change in pipe diameter causes changes in fluid velocity and pressure. The orifice meter is simpler, consisting of a flat plate with a hole in it, which gauges flow the same way but lacks the diverging and converging zones of the venturimeter.

Examples & Analogies

Imagine a garden hose with a nozzle at the end. When you partly cover the nozzle, the water speeds up and shoots out farther. Similarly, in a venturimeter, the fluid speeds up when it flows through the narrower section, which is similar to how the hose gets more pressure when constricted.

Pressure Difference Measurement

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

We can measure the pressure difference at two locations; one is at the fiber locations where the cross sections is really less and another is the off stream locations. That pressure difference and if you apply simple Bernoulli equations and the mass conservation equation, you can find out what will be the discharge passing through venture or orifice meters.

Detailed Explanation

In a venturimeter, the fluid speed and pressure are inversely related due to the conservation of energy as described by the Bernoulli equation. When fluid moves through the narrower section, its speed increases, causing the pressure to drop. By measuring the pressure at two points, one where the pipe is narrower (lower pressure) and one where it is wider (higher pressure), and applying the Bernoulli equation, we can determine the discharge, which is the volume of fluid flowing through per unit time.

Examples & Analogies

Think of how a doctor measures blood pressure using a cuff. The cuff squeezes the arm (similar to a venturimeter’s narrower area) and reduces the flow of blood. The pressure drops as the arm constricts, and by measuring this, the doctor can determine how efficiently the blood is flowing.

Coefficient of Discharge

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Because of the energy losses, there will be difference between theoretical discharge and actual discharge... Therefore, we introduce a coefficient of discharge, that means the CD.

Detailed Explanation

When flowing through a venturimeter or orifice meter, the ideal conditions assumed in the Bernoulli equation do not account for energy losses due to friction and turbulence. Hence, we cannot fully rely on the theoretical discharge calculated. The coefficient of discharge (CD) is introduced to account for these losses, defined as the ratio of actual discharge to theoretical discharge. It helps in determining realistic flow rates and is critical for engineers to ensure accurate designs and measurements.

Examples & Analogies

It's like trying to guess how fast a running car could go based only on its horsepower without considering drag and friction. Just as engineers need to factor in drag to be more accurate in their speed estimates, the coefficient of discharge allows us to better understand how much fluid will actually flow through the meter despite losses.

Energy Losses and Flow Patterns

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Whenever flow goes through these venturimeter or orifice meter, there will be energy losses. Because of that, what do you will have, your theoretical discharge compute from the Bernoulli equations and the mass conservations will be more than actual discharge.

Detailed Explanation

In real-world applications, as fluid flows through the venturimeter or orifice you will experience energy losses due to friction, turbulence, and other factors. These factors cause actual discharge to be lower than the theoretically calculated discharge based on Bernoulli's principles. Therefore, understanding these energy losses is crucial in fluid dynamics, leading to improved designs and more accurate predictions of flow.

Examples & Analogies

Imagine a slide at a water park. The water flows quickly at the start, but as it moves down the slide, it encounters friction against the slide's surface and air resistance. This friction slows down the flow of water, similar to how energy is lost in a venturimeter. In both cases, the expected speed or flow rate gets reduced due to these losses.

Key Concepts

-

Venturimeter: A device that measures fluid flow rate by using pressure differences created by flow area changes.

-

Bernoulli's Equation: A relation connecting pressure, velocity, and height in fluid mechanics, fundamental for computing flow rates.

-

Coefficient of Discharge: A vital parameter accounting for discrepancies between ideal and actual fluid flows.

-

Kinetic Energy Correction Factors: Adjustments made to kinetic energy calculations that take into account variable velocity distribution across a flow.

Examples & Applications

A venturimeter is used in an industrial pipeline to measure the flow rate of water, ensuring optimal operation of the system.

In municipal water supply systems, venturimeters help monitor and regulate water flow to different regions efficiently.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In a venturimeter, flow does dance, / Pressure drops, gives flow a chance.

Stories

Imagine a river narrowing, flowing faster, creating a whirlpool of motion; every millimeter of closure brings forth a rush of speed—this mirrors how a venturimeter works, transforming flow dynamics thoughtfully.

Memory Tools

For flow rate efficiency, remember 'P-V-H' for Pressure, Velocity, and Height in Bernoulli's equation.

Acronyms

KAPS = Kinetic energy, Actual discharge, Pressure difference, and Systems in fluid mechanics.

Flash Cards

Glossary

- Venturimeter

A device used to measure the flow rate of liquid through a pipe by creating a pressure difference.

- Bernoulli Equation

A principle that describes the relationship between pressure, velocity, and height in incompressible flows.

- Coefficient of Discharge (C_D)

A dimensionless number that represents the ratio of actual discharge to theoretical discharge in flow measurements.

- Kinetic Energy Correction Factor (α)

A factor used to adjust kinetic energy calculations for non-uniform velocity distributions.

- Static Pressure

The pressure exerted by a fluid at rest.

- Dynamic Pressure

The pressure associated with the fluid's velocity.

- Stagnation Pressure

The pressure exerted by a fluid when it is brought to rest from its flow velocity.

Reference links

Supplementary resources to enhance your learning experience.