Energy Transfer in Pump

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Hydraulic and Energy Gradient Lines

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss hydraulic and energy gradient lines. Can anyone tell me what the hydraulic gradient line indicates?

Is it the line that shows how the pressure changes in a system?

Exactly! In open channel flow, it coincides with the liquid's free surface. How about the energy gradient line?

Does it include velocity components when we measure energy?

Great point! The energy gradient line incorporates the velocity head as well. Remember the acronym 'HVE' for Hydraulic Gradient, Velocity head, and Energy Gradient lines. Let's visualize how these lines change in a flow system.

What happens when we measure these in pipes?

In pipes, we can use piezometers for hydraulic gradient measurements and pitot tubes for energy gradient measurements. This leads us to understand pressure changes!

So, pressure readings will vary based on these changes?

Yes! And remember the relationship—when pressure head is zero, it aligns with open channel scenarios. Let's summarize: hydraulic gradient lines represent pressure changes, while energy gradient includes kinetic aspects.

Energy Transfer Mechanisms

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive into energy transfer in pumps. Can someone explain how a pump increases fluid energy?

By raising the pressure of the fluid, right?

Correct! Remember, pumps increase mechanical energy to transfer it to fluid. What about turbines?

Turbines extract energy, which drops the pressure!

Exactly! Turbines convert fluid energy back into mechanical energy. The fundamental understanding here is how pressure changes correlate with energy transfer. Let’s apply the 'PEE' theory: Pump increases energy, Turbine extracts energy.

Is the pressure itself considered energy?

Good question! Pressure is a measure of potential energy per volume, but not energy itself. Let's reinforce this: pressure reflects capacity to do work in fluid systems.

Bernoulli Equation Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss the Bernoulli equation. How can we use it to analyze between two points in a fluid system?

We compare pressure, velocity, and elevation, right?

Exactly! It allows us to quantify energy differences. If we have a dam, for example, and water flows through a turbine, how would that be expressed?

We need to account for changes in potential energy and kinetic energy?

Correct! The differences in specific energy can help us determine net energy efficiency in these setups. Remember to always factor in efficiency losses when calculating actual outputs. The formula would be E = P + 0.5V^2 + gh.

What happens if we ignore losses?

Ignoring losses gives us ideal values, but efficiency drops significantly in real-world applications. Always apply your understanding of conservation laws. Let's summarize: Bernoulli's equation is a tool for analyzing energy transformations in fluid dynamics.

Understanding Efficiency in Fluid Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's explore efficiency in our systems. Why do we care about efficiency in pumps and turbines?

To understand how effectively they convert energy!

Absolutely! Efficiency measures how much input energy is converted into useful work. Can anyone define efficiency for pumps?

It’s the ratio of output mechanical power to input power, right?

Yes, and turbines follow the same principle but in reverse. Understand losses such as heat and sound are critical to calculating these efficiencies. Reflect on the acronym 'EPR' for Efficiency, Power, and Ratios.

How do we account for these losses?

Typically through empirical experiments yielding an efficiency percentage. High-quality systems aim for as little energy loss as possible. Let’s summarize: efficiency indicates the effectiveness of energy conversion in fluid machinery.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section provides an overview of how mechanical energy is transferred to fluid in pumps, leading to pressure increases, and how turbines extract energy, causing pressure drops. It also explains fundamental concepts like hydraulic and energy gradient lines, and how they are measured in different flow conditions.

Detailed

Detailed Summary

In this section, we explore the concepts of energy transfer in pumps and turbines. We start by noting that in open channel flow, the hydraulic gradient line coincides with the free surface of the liquid, as there is no pressure head. In contrast, in a pipe system, changes in pressure can be measured using devices like piezometers and pitot tubes. The pressure head becomes atmospheric pressure at pipe exits, and thus, the hydraulic gradient aligns with the outlet. As mechanical energy encounters friction, losses occur, causing the energy gradient line to slope downward in the direction of flow, which also affects the hydraulic gradient line.

The section further elaborates on how pumps transfer mechanical energy to fluid by increasing its pressure, while turbines do the opposite by extracting energy from fluid, resulting in reduced pressure. Importantly, pressure is understood not as a form of energy but as stored potential energy per unit volume. Using the Bernoulli equation, one can analyze energy exchanges between two points in a flow system, taking into account factors such as height, velocity, and pressure.

Lastly, the section touches on efficiency within pump and turbine systems and emphasizes that energy losses are inevitable due to factors like heat and sound, leading to a need for efficiency calculations. The key takeaways include understanding the relationship between energy, pressure, and fluid mechanics within hydraulic systems.

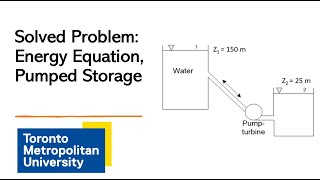

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Pumps and Turbines

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, let us consider the problems when we generally use as engineers having a pump and turbine systems. As you know it, the pump transfers mechanical energy to fluid by rising pressures. The turbine does the opposite, extracting mechanical energy from the fluid by dropping its pressure.

Detailed Explanation

Pumps and turbines are essential components in fluid mechanics. A pump typically adds energy to a fluid by increasing its pressure, which allows the fluid to flow more freely through a system. On the other hand, a turbine extracts energy from a moving fluid, causing a drop in pressure as it converts that energy into mechanical work.

Examples & Analogies

Think of a pump as a heart that pumps blood (fluid) through the arteries (pipes) in your body, increasing its pressure to ensure that it reaches all organs. Conversely, a water wheel (turbine) at a mill uses the energy of flowing water to turn, producing work as the water’s pressure drops.

Understanding Pressure Energy

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Pressure itself is not a form of energy; it is just flow energy or storage potential energy per unit volume. If I consider the two points, I differentiate between these two energy states to show the net energy difference.

Detailed Explanation

While we often think of pressure as energy, it is better understood as a measure of the energy contained in a specific volume of fluid. This concept is crucial in analyzing fluid systems because it helps us identify how much mechanical work can be done based on the energy available in the fluid. Comparing different energy states allows engineers to calculate the energy that can be extracted or added through pumps and turbines.

Examples & Analogies

Imagine a balloon filled with air. The air inside the balloon is under pressure, which is similar to potential energy. When you release the balloon, the pressure energy is converted to kinetic energy as the air rushes out, moving the balloon in the opposite direction.

Efficiency of Pumps and Turbines

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Whenever we have a system, there are energy losses. We cannot convert total mechanical energy entirely from mechanical pump or turbine; there will be some heat energy losses and sound energy losses, which affects efficiency.

Detailed Explanation

In real-world applications, pumps and turbines do not operate at 100% efficiency due to various factors such as friction and heat loss. This inefficiency means that not all input energy is converted to useful energy output. To quantify performance, engineers calculate the efficiency ratio, which helps indicate how well the devices convert energy from one form to another.

Examples & Analogies

Think about a car engine. Not all the fuel energy you put into it is used to move the car forward; some energy is lost as heat and noise. This inefficiency means that for every gallon of fuel, only a portion is used effectively for motion, similar to how energy is sometimes lost in pumps and turbines.

Understanding the Bernoulli Equation

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If I look at the Bernoulli equations, I have three terms that define us as energy terms, okay. For example, between two locations, I find out what is the mechanical energy difference between these two parts.

Detailed Explanation

The Bernoulli equation relates pressure, velocity, and height (elevation) of a fluid in motion and is a cornerstone of fluid dynamics. By applying this equation, engineers can determine energy changes as fluid moves through various points, thus predicting how pumps and turbines will function under different conditions. The key is recognizing that the total mechanical energy remains constant along a streamline, barring any energy losses.

Examples & Analogies

Imagine water flowing down a slide. At the top, the water has a lot of potential energy (height), which converts to kinetic energy (speed) as it reaches the bottom. Using the Bernoulli equation helps predict how fast the water will be moving based on its height at different points on the slide.

Pressure Gradients in Pipes

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Mechanical energy losses due to frictional effects convert energy from the hydraulic gradient line to a slope downward in the direction of flow. There will be slow downward in the direction of flow of energy gradient lines and also the hydraulic gradient lines.

Detailed Explanation

As fluid flows through a pipe, it experiences resistance due to friction with the pipe walls, leading to energy losses. This is shown by a downward slope in the hydraulic gradient line, indicating that pressure decreases along the direction of flow. Understanding this gradient helps engineers design more efficient piping systems and optimize pump placement to combat these losses.

Examples & Analogies

Consider sliding down a hill. The steeper the hill, the faster you go, but as you encounter rough terrain (like friction), your speed decreases. Similarly, when fluid flows through pipes, friction slows down the flow and reduces available pressure.

Key Concepts

-

Hydraulic Gradient Lines: Indicate pressure changes in fluid systems.

-

Energy Gradient Lines: Reflect total fluid energy including velocity head.

-

Pressure Changes: Occur at pipe outlets, indicating energy transformations.

-

Bernoulli's Equation: Model for energy conservation in fluid dynamics.

-

Mechanical Efficiency: Ratio of useful output relative to input energy.

Examples & Applications

In a system with a pump, if the pressure at the inlet is 50 kPa and at the outlet is atmospheric pressure, the pump must generate a pressure difference, showcasing energy transfer.

Using the Bernoulli equation, a water system with varying elevation can demonstrate how energy drops due to height changes and how that translates to fluid velocity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In a pump there's a thrust, pressure rises, it's a must, through the pipes, the fluids go, energy's high, watch it flow!

Stories

Imagine a water park where children climb to the top of a slide (high pressure) before flying down (low pressure), illustrating energy transfer.

Memory Tools

Remember 'PEE' for Pumps Elevate Energy and 'TEN' for Turbines Extract Energy Needs.

Acronyms

Use 'HAVE' - Hydraulic gradient, Potential energy, and Velocity head to remember key energy concepts.

Flash Cards

Glossary

- Hydraulic Gradient Line

A line that represents the pressure head in a flow system, coinciding with the fluid's free surface in open channel flow.

- Energy Gradient Line

A line that includes the velocity head and indicates the total energy available in a fluid flow system.

- Bernoulli Equation

An equation that relates pressure, velocity, and elevation in a fluid flow system, demonstrating energy conservation.

- Mechanical Energy Losses

Energy losses that occur due to friction, heat, sound, and other factors when fluid flows through a system.

- Efficiency

The ratio of the useful output of a process to the input, expressed as a percentage.

- Piezometer

A device used to measure the pressure head of a fluid in a pipe.

- Pitot Tube

A device that measures fluid flow velocity by converting kinetic energy into potential energy.

Reference links

Supplementary resources to enhance your learning experience.