Fluid Flow Analyses

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Open Channel vs Pipe Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll delve into fluid flow analyses by comparing open channel flows with pipe flows. Can anyone tell me what the hydraulic gradient line looks like in open channels?

Is it the same as the free surface of the liquid?

Exactly! The hydraulic gradient line matches the free surface because there's no pressure head. Now, what happens in pipes?

We can measure pressure heads with devices like piezometers.

Right! In pipes, we use pressure head observations. Let me help you remember this: Think of 'Piezometer' - 'Pressure Indicator.'

So, it’s like having a tool to measure water pressure?

That's correct! Pressure in pipes is crucial for analyzing flow dynamics. Let's summarize: Open channels show hydraulic gradients at the free surface, while pipes require specific tools for measurement.

Energy Gradients and Mechanical Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand hydraulic gradients, let’s talk about energy gradient lines. What are mechanical energy losses in our systems?

Are those because of friction?

Exactly! As fluid flows, it experiences frictional losses, which can transform mechanical energy into heat. Can anyone explain how these losses affect the hydraulic gradient line?

It slopes downwards in the direction of flow, right?

Absolutely! The energy gradient line also slopes down as a result. Remember: 'Friction = Friction Loss'. Let's recap: Mechanical energy losses due to friction cause energy and hydraulic gradients to slope down.

Function of Pumps and Turbines

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's focus on the roles of pumps and turbines in our fluid systems. Can someone describe how a pump functions?

Pumps increase fluid pressure, right?

Correct! They convert mechanical energy into fluid energy by increasing pressure. What about turbines?

They extract energy from the fluid, lowering its pressure.

Yes, great observation! Here's a tip: For pumps, think 'Push up' and for turbines, think 'Take down'. Now, let’s summarize: Pumps raise pressure while turbines lower it.

Bernoulli's Principle Application

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

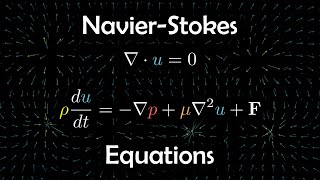

Let’s apply Bernoulli’s equation to analyze fluid systems. What do we need to consider when using this equation?

We need points between which we are measuring energy differences.

Correct! Bernoulli's principle helps us see how energy is conserved in the flow. Can anyone think of factors that might affect these energy calculations?

Velocity changes and pressure differences?

Spot on! Keep in mind: 'Energy = Velocity + Pressure'. This will help you remember the key elements.

So, it's like balancing energy across different points in a flow?

Exactly! Final recap: Bernoulli's equation balances energy between different flow points. Consider velocity and pressure tightly!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section explains how hydraulic gradient lines and energy gradient lines function in open channel flows and pipe flows, including the effects of mechanical energy losses due to friction. It also introduces the operation of pumps and turbines, alongside the concept of efficiency within these systems.

Detailed

Fluid Flow Analyses

Understanding fluid flow is critical in various engineering applications. In this section, we analyze the hydraulic gradient and energy gradient lines crucial for both open channel and pipe flows.

Key Points:

- Free Surface Representation: In open channel flows, the hydraulic gradient line coincides with the free surface of the liquid since pressure head is absent. Energy gradient lines include the velocity head above the free surface.

- Pipe Flow Dynamics: For pipe flows, the use of piezometers and pitot tubes helps determine hydraulic and energy gradients, respectively.

- Pressure Dynamics: At a pipe exit where flow is discharged into the atmosphere, the pressure head equals atmospheric pressure, causing the hydraulic gradient to align with the outlet.

- Mechanical Energy Losses: Frictional effects can result in mechanical energy losses from thermal energy, causing hydraulic and energy gradient lines to slope downwards along the flow direction.

- Energy Transition in Pumps and Turbines: Pumps increase mechanical energy by raising pressure, while turbines extract energy, reducing pressure. Understanding this transition is vital for efficient fluid transport systems.

- Bernoulli's Principle: Applications of Bernoulli's equation help in analyzing energy changes between two points in fluid flow.

- Efficiency Considerations: The efficiency of pumps and turbines is defined by the ratio of output to input power, emphasizing the importance of effective energy transfer in fluid systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Hydraulic Gradient and Energy Gradient in Open Channel Flow

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In case of open channel flow, the hydraulic gradient lines coincide with the free surface of the liquid because there is no pressure head. The energy gradient lines will include the velocity head above the free surface. This means, for open channel flow, the free surface represents the hydraulic gradient line, and adding the velocity head will give the energy gradient line.

Detailed Explanation

In open channels, the liquid's surface (like a river or a canal) defines the hydraulic gradient since there isn’t any pressure pushing down from above it (like in a pipe). Since the only energy contributing to the flow is gravitational and kinetic (velocity), the energy gradient includes the height of the water surface (potential energy) and its velocity (kinetic energy). Hence, we can say that in open channel flow, there is a direct correlation between the flow dynamics and these energy levels.

Examples & Analogies

Think of a water slide. The water flows down the slide, and the height of the slide (like the water surface) indicates the potential energy. The speed of the water at any point on the slide indicates the kinetic energy. Just as there’s no pressure pushing the water down the slide, in an open channel flow, the hydraulic gradient relies on the water's surface alone.

Pressure Head at Pipe Exits

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Whenever a pipe exits into the atmosphere, the pressure head at the outlet becomes atmospheric pressure, which means the hydraulic gradient lines coincide with the pipe outlet.

Detailed Explanation

At the end of a pipe where it discharges into the atmosphere, the water pressure inside the pipe is typically balanced with the atmospheric pressure. Therefore, we consider this pressure head to be zero, and the hydraulic gradient aligns with the water's exit point. The hydraulic gradient can also be used to predict fluid behavior at pipe exits based on changes in pressure.

Examples & Analogies

Imagine a balloon filled with water. When you poke a hole at the end of the balloon, the water flows out, and the pressure is equal to the air pressure outside. The water level drops to match the exit, just like the hydraulic gradient at the end of a pipe matches the outlet.

Mechanical Energy Losses

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Mechanical energy losses due to friction convert thermal energy and cause the energy gradient line and hydraulic gradient line to slope downwards in the direction of flow.

Detailed Explanation

As fluid moves through a piping system, friction between the fluid and walls leads to energy losses, which results in a decrease in the total mechanical energy of the fluid. This loss means that both the energy gradient line and the hydraulic gradient slope down as the fluid flows, indicating these losses throughout the system. Understanding this is crucial for designing efficient fluid systems where minimizing such losses is possible.

Examples & Analogies

Consider sliding down a slide. If the slide is smooth, you go down quickly (less friction means better energy retention). If it's rough, you slow down (more energy lost to friction). The same principle applies to fluid flow in pipes.

Pressure Distribution Relating to Hydraulic Gradient Line

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When pressures in flow sections lie above the hydraulic gradient line, it indicates negative pressure, and when they lie below, it represents positive pressure. We solve pipe flow problems by looking at how pressures change relative to this line.

Detailed Explanation

The position of the pressure relative to the hydraulic gradient line indicates whether it’s under pressure (positive) or vacuum (negative). This concept is essential in analyzing fluid systems because it helps engineers diagnose issues, design systems, and predict flow behavior by assessing how pressures interact with the hydraulic gradient.

Examples & Analogies

Think of a sealed bottle of soda. If you shake it, pressure builds inside (above the line). When you open it, the pressure drops to atmospheric (below the line). Understanding this helps in knowing when it’s safe to open and what to expect!

Operation of Pumps and Turbines

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Pumps transfer mechanical energy to fluid by increasing pressure, while turbines extract mechanical energy from the fluid by decreasing pressure.

Detailed Explanation

In a pumping system, energy is added to the fluid, which increases its pressure and enables it to flow through systems. Conversely, turbines function to convert kinetic energy from moving fluid back into mechanical work, effectively using the fluid's pressure drop to perform work. Understanding how these interactions work is vital for designing efficient hydroelectric systems, irrigation, and various industrial fluid transport systems.

Examples & Analogies

Picture a bicycle pump. When you push down, you compress air (increasing pressure). In a similar way, pumps push water to increase pressure. Now think of a water wheel; as water flows over it, it pushes the wheel to generate energy. Both are perfect examples of how pressure changes can create useful energy.

Efficiency in Fluid Systems

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

There are energy losses in pump and turbine systems that are not limited to mechanical losses, as heat and sound are also factors, leading to efficiency calculations.

Detailed Explanation

Efficiency is a measure of how much input energy was effectively transformed into useful output energy. A system’s efficiency accounts for all types of losses, such as those from heat and sound, as well as friction losses. Mathematically, it is expressed as the ratio of useful output energy to the energy supplied. Recognizing these losses contributes significantly to the design and optimization of energy systems.

Examples & Analogies

Imagine a car's fuel efficiency. The more efficiently it uses its fuel to move, the further you can travel on the same amount of gas. If the engine generates a lot of heat or noise and doesn't convert fuel to movement effectively, it reduces efficiency. Fluid systems work on the same principle!

Key Concepts

-

Hydraulic Gradient: The pressure head representing the energy distribution along a flow.

-

Energy Gradient: The total energy, including kinetic and potential energy, in fluid flow.

-

Mechanical Energy Losses: Energy wasted due to friction and turbulence in the flow.

-

Pumps: Devices increasing fluid energy and pressure.

-

Turbines: Devices extracting energy from the fluid, lowering its pressure.

Examples & Applications

In an open channel, the hydraulic gradient line coincides with the water surface, demonstrating the absence of pressure head.

When fluid exits a pipe into the atmosphere, the pressure at the outlet equals atmospheric pressure, aligning the hydraulic gradient.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Pumps go up, turbines go down, keeping energy flows all around.

Stories

Imagine a water park where water slides represent fluid flows. The slopes simulate energy loss - the steeper, the faster the ride, but also the greater the splash (energy loss) at the end before it calms down.

Memory Tools

HPE for Fluid Analysis: H for Hydraulic gradient, P for Pressure measurements, and E for Energy conservation.

Acronyms

FLUID

Flow

Loss

Up

In

Down (representing fluid flow dynamics).

Flash Cards

Glossary

- Hydraulic Gradient Line

The line representing the hydraulic head over a flow section in liquid.

- Energy Gradient Line

A line representing the total energy head, including velocity head, in a flow.

- Mechanical Energy Losses

Energy losses in a system due to friction and turbulence.

- Piezometer

A device used to measure the pressure head of a liquid.

- Pitot Tube

An instrument used to measure fluid flow velocity.

- Bernoulli's Equation

An equation that relates the pressure, velocity, and height in fluid dynamics.

Reference links

Supplementary resources to enhance your learning experience.