Pressure Difference Calculation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Hydraulic Gradient Lines

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's begin by understanding hydraulic gradient lines. In open channel flow, can anyone tell me what happens to the hydraulic gradient line?

Is it at the water surface level?

Exactly! The hydraulic gradient line coincides with the free surface of the liquid because there is no pressure head. Now, how does this change in a pipe?

In a pipe, the pressure head can be measured using devices like piezometers.

Correct! So when we exit a pipe to the atmosphere, the pressure head becomes atmospheric pressure, creating a reference for hydraulic gradients. This is crucial for analyzing fluid dynamics.

So, can we always assume that the hydraulic gradient line coincides with atmospheric pressure in pipes?

Yes, that’s right! It’s important to remember this when solving problems. The relationship between pressures and gradient lines helps us understand how energy is lost in a system.

Mechanical Energy Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about mechanical energy losses in fluid systems. What do you think causes these losses?

Friction in the pipes, right?

Exactly! Frictional effects convert mechanical energy to thermal energy, causing our energy gradient lines to slope downwards in the direction of flow. Can anyone explain the difference in pressure regarding these lines?

If the pressure lies above the hydraulic gradient line, it’s negative. Below it is positive?

Very good! Understanding this difference helps us when calculating pressure changes through various sections of a flow system.

Pumps and Turbines

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's explore how pumps and turbines function within these systems. Can anyone summarize what pumps do?

Pumps increase the fluid's pressure, adding energy to it.

That's right! What about turbines?

Turbines extract energy from the fluid, lowering its pressure.

Correct again! The interaction between these devices and the fluid is essential for determining overall system efficiency. How do we calculate efficiency?

Efficiency is the ratio of useful output energy to the input energy.

Exactly! Understanding these components helps us assess how effectively our flow systems operate.

Energy and Power Calculations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's perform some energy and power calculations. Why is it essential to know the power generated by turbines?

To determine how well the turbine converts fluid energy into usable power?

Exactly! For example, if we know the mass flow rate and the difference in pressure, we can calculate the power output.

Can you show us a sample calculation?

Sure! Let’s say we have a pressure difference of 1000 Pa and a mass flow rate of 0.5 kg/s. How would we calculate power?

Power equals pressure difference times mass flow rate, so it would be 1000 times 0.5?

Exactly! That gives us 500 watts. Always remember, understanding these formulas allows you to assess the effectiveness of fluid systems comprehensively.

Practical Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s discuss practical applications. How do you see these principles applied in everyday technology?

In water supply systems and even in automotive engines!

Excellent! Both systems use the concepts of pressure and energy dynamics we've discussed today. What about using Bernoulli's equation in a venturi meter?

It helps measure fluid flow rates by observing pressure changes across different pipe diameters.

Correct! And this highlights the importance of understanding pressure differences in engineering fields.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

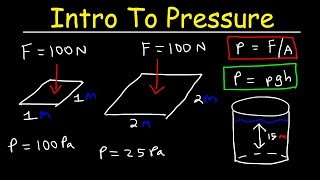

The section details how pressure and energy gradients behave in open channel flows compared to pipe flows, highlighting the significance of pressure heads, mechanical energy losses, and efficiency in pump and turbine systems.

Detailed

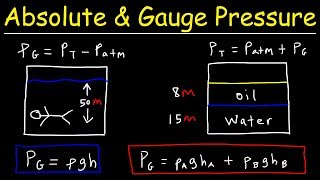

In fluid dynamics, understanding pressure difference calculations is crucial. This section begins by distinguishing between open channel and pipe flow, noting that in open channels, the hydraulic gradient line coincides with the liquid's free surface due to the absence of pressure head. In contrast, pressure heads can be measured in pipes using piezometers or pitot tubes, reflecting energy gradient lines that include contributions from velocity heads. The section discusses how the exit of a pipe results in atmospheric pressure, establishing the hydraulic gradient, and addresses mechanical energy losses that manifest as downward slopes in energy and hydraulic gradient lines. Various dynamic components like pumps and turbines are presented, illustrating how they either increase or decrease pressure and thus alter energy within a system. Moreover, specific calculations of power generated by these systems are explored, alongside efficiency metrics that clarify energy losses. Practical examples and challenges extend the theoretical aspects, requiring students to apply Bernoulli's equation and continuity principles. This comprehensive exploration supports students' understanding of fluid mechanics in practical applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Hydraulic Gradient in Open Channel Flow

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Whenever a pipe exit, that means flow is going out. The pressure head becomes atmospheric pressure, no doubt about that. The hydraulic gradient line coincides with the pipe outlet.

Detailed Explanation

In an open channel flow, the hydraulic gradient line aligns with the free surface of the liquid because there is no pressure head. When water exits a pipe, the pressure head at the outlet drops to atmospheric pressure, leading the hydraulic gradient line to also coincide with this outlet level. This information is crucial for understanding how the flow behaves at the surface layer of liquids rather than being under pressure, which is often the case in closed systems like pipes.

Examples & Analogies

Imagine a water slide. When you reach the end of the slide, the water exits into the air at the same height as your feet (the free surface). Just like this, when a pipe discharges water, the hydraulic gradient aligns with the water's exit level, indicating the available energy at that point.

Energy Losses in Pipe Flow

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Mechanical energy losses due to the frictional effects, which converts thermal energy, causes the energy gradient line and hydraulic gradient line to slope downwards in the direction of flow.

Detailed Explanation

In fluid flow, as the liquid travels through a pipe, it experiences friction that takes away some of its mechanical energy. This energy loss is represented by a downward slope of both the energy gradient line and the hydraulic gradient line. Essentially, as fluid moves from one point to another, it loses some energy due to friction, affecting the overall pressure and energy available at different points of the system.

Examples & Analogies

Think of riding a bike uphill versus downhill. As you pedal uphill, you work harder against gravity and friction, losing kinetic energy, while going downhill allows you to gain speed freely. Similarly, in pipes, the fluid loses energy primarily due to friction with the pipe walls.

Pressure References in Flow Sections

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Pressure in a flow section that lies above the hydraulic gradient line is negative, while pressure in a section that lies below it is positive.

Detailed Explanation

The position of a flow section relative to the hydraulic gradient line determines whether the pressure is considered positive or negative. If the pressure at a particular section is above this line, it indicates a zone of lower pressure (negative), while below the line indicates higher pressure (positive). This concept is essential for understanding how pressure variations affect fluid flow and energy in a system.

Examples & Analogies

Imagine a barometer, where mercury rises higher when there is lower atmospheric pressure. Similarly, in fluid dynamics, areas where the pressure is lower than the hydraulic gradient indicate 'vacuum-like' conditions. This helps engineers predict where fluids will move and how they behave in various environments.

Mechanical Energy in Pump and Turbine Systems

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

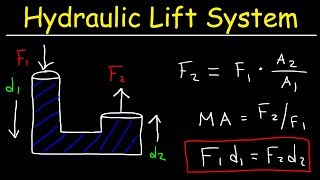

A pump transfers mechanical energy to a fluid by raising its pressure, while a turbine extracts mechanical energy from the fluid by lowering its pressure.

Detailed Explanation

Pumps and turbines play crucial roles in fluid systems. Pumps work by increasing the pressure of the fluid, effectively adding energy to the system and allowing for upward flow. On the other hand, turbines extract energy from the fluid, converting flow energy into another form (like electricity or mechanical work) by lowering the pressure. This dynamic between pumps and turbines illustrates how energy is managed in fluid systems.

Examples & Analogies

Consider a water park. The pumps raise the water to the top of the slides, giving it potential energy to flow down. When riders descend, the turbines may harness that flowing water's energy to generate electricity. This is similar to how pumps add energy, while turbines take energy away in fluid systems.

Key Concepts

-

Pressure Gradient: The difference in pressure between two points in the flow that causes fluid movement.

-

Energy Loss: The reduction of total mechanical energy in a fluid system due to factors like friction.

-

Pump Efficiency: How effectively a pump converts mechanical energy into fluid flow energy.

-

Turbine Efficiency: The effectiveness in extracting energy from the fluid.

Examples & Applications

In a water supply system, if water exits a pipe at atmospheric pressure, the hydraulic gradient line will flatline at that outlet.

In a simplified model, when calculating power generated by a turbine, knowing the pressure drop across it allows for efficient energy measurements.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Pipes go up, pipes go down, pressure and flow spin around.

Stories

Imagine water flowing from a pump, squeezing through a tube like toothpaste. The pressure pushes it out to your faucet, showing how energy, pressure, and flow work together.

Memory Tools

PEM: Pressure, Energy, Motion - remember these key elements in fluid calculations.

Acronyms

PHE

Pump

Hydraulic

Efficiency - think of this during discussions on pumps and their role in systems.

Flash Cards

Glossary

- Hydraulic Gradient Line

A line that represents the hydraulic head in a fluid flow system, typically coinciding with the free surface in open channel flows.

- Energy Gradient Line

A line that shows the total energy in a fluid system including kinetic and potential energy components.

- Piezometer

A device used to measure the pressure head in a fluid at a particular point.

- Coefficient of Discharge (Cd)

A dimensionless number that represents the efficiency of fluid flow through an orifice or venturimeter compared to theoretical flow.

- Efficiency

The ratio of the useful work output to the energy input, indicating how effectively a machine converts energy.

- Mass Flow Rate

The mass of fluid passing through a given surface per time, often used in power calculations.

Reference links

Supplementary resources to enhance your learning experience.