Pump and Turbine Systems

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Hydraulic Gradient Lines

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will delve into hydraulic gradient lines. In open channel flow, the hydraulic gradient lines coincide with the free surface of the liquid because there is no pressure head. Can anyone explain why this is significant?

It means that the energy in the flow is represented by the water surface, right?

Exactly! And in piping systems, as fluid exits the pipe, the pressure corresponds to atmospheric pressure. This means the hydraulic gradient line rests at the pipe outlet. Remember the acronym 'HPE' for Hydraulic, Pressure, Energy to recall these concepts.

What happens when the pressure head drops or there's mechanical energy loss?

Great question! The energy gradient line will slope downwards due to mechanical energy losses. These concepts are essential for understanding how pumps and turbines work.

So, if the hydraulic gradient line intersects the fluid, is the gauge pressure zero at that point?

Yes! When the hydraulic gradient line intersects the fluid, it indicates a zero gauge pressure. Remember this when calculating pressure in flow sections!

In summary, hydraulic gradient lines relate directly to the energy available in the fluid, which is crucial when designing systems.

Pumps and Turbines

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss how pumps and turbines transfer mechanical energy. A pump increases the fluid pressure, allowing it to gain energy. Can anyone give me an example of where we might find pumps being used?

In our campus water supply system!

Correct! And turbines do the opposite by extracting energy from the fluid, which lowers its pressure. Think of hydropower projects using turbines. Remember 'EPE' for Energy Pump Extraction; it summarizes the pump-turbine relationship.

How do we calculate the power from these systems?

Power is calculated from the mechanical energy difference multiplied by the mass flow rate. For ideal systems, we can consider maximum efficiency reducing practical calculations.

What happens with energy losses in these systems?

Excellent point! Friction and other losses decrease efficiency, which is crucial when evaluating system performance. Always remember to account for these in real-world applications!

To conclude this session, pumps add mechanical energy while turbines extract it, both integral in fluid dynamics and systems design.

Energy Gradient and Efficiency

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now moving to energy gradient lines. These lines represent the total mechanical energy in flowing fluids. Why do you think it’s essential to evaluate these lines?

To understand how well the system is working?

Precisely! The energy gradient line's slope indicates mechanical energy loss. Does anyone remember what factors contribute to these losses?

Friction and heat, right?

Exactly! Losses impact efficiency, which determines how effective our energy transfer is. Can anyone recall how to calculate efficiency?

It’s the ratio of input to output power, I think?

Correct! Evalulating efficiency helps in designing optimal fluid systems. For practical understanding, ensure to use formulas for efficiency to keep these systems efficient!

In summary, evaluating energy gradients and efficiency is vital for enhancing system performance in pumps and turbines.

Example Problems and Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let's apply what we've learned through some example problems. The first problem shows how a venturimeter affects flow. Who can summarize the steps to solve it?

We need to apply the Bernoulli equation, right?

Absolutely! Begin by defining the flow classification, then use mass conservation before applying Bernoulli’s equations. What's the first thing we need to assume?

That the flow is steady and incompressible?

Exactly! Once you’ve established the flow assumptions, you can derive the mass flow rates across different areas. Can anyone predict the outcome?

It should yield a pressure difference related to the flow rate?

Correct! Understanding the relationship helps in calculating coefficient of discharge as well. Always verify your results against the expected as a best practice!

To summarize, practice solving example problems effectively utilizes the principles covered today!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section offers insights into the operation of pumps and turbines, emphasizing pressure differences in fluid mechanics, energy gradient lines, and the role of hydraulic gradient lines in pipe flow systems. It explains how mechanical energy is transferred to fluids to enhance flow and discusses calculations related to energy loss and efficiency.

Detailed

Pump and Turbine Systems

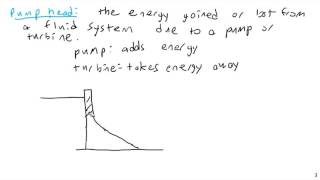

This section dives into the mechanical operations of pump and turbine systems, essential in fluid mechanics. It begins by elucidating the concepts of hydraulic and energy gradient lines, especially in open channel flow, where the free surface of the liquid coincides with the hydraulic gradient line due to the absence of pressure head. Contrastingly, in piping systems, pressure heads can be measured using piezometers, influencing both the hydraulic and energy gradient lines.

Key Concepts Covered

- Pressure and Hydraulic Gradient Lines: In pipes, as fluid exits into the atmosphere, the pressure head becomes atmospheric, making the hydraulic gradient line coincide with the pipe outlet. The section explains mechanical energy losses due to friction, which affect the energy gradient line.

- Energy and Mechanical Energy Losses: Mechanical energy is transferred to fluid through pumps, which increase pressure, while turbines extract mechanical energy by reducing pressure. The relationship between pressure and energy is explored using Bernoulli's equations.

- Efficiency of Energy Systems: The efficiency of pumps and turbines is critical in determining the effectiveness of the energy transfer. Various losses—including heat and sound—reduce system efficiency, necessitating calculations for practical applications.

- Example Problems: The section illustrates the application of mass conservation and Bernoulli equations through example problems, enabling students to calculate theoretical discharge, coefficient of discharge, and pressure differences in fluid flow scenarios.

By understanding the fundamentals of pump and turbine systems, students can resolve flow design issues effectively and analyze hydraulic structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Basic Principles of Pumps and Turbines

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

As you know, the pump is transfer from mechanical energy to fluid by rising pressures. The turbine does the opposite, extracting mechanical energy from the fluid by dropping its pressure.

Detailed Explanation

Pumps and turbines are crucial components in fluid systems. A pump works by adding mechanical energy to a fluid, which results in an increase in the fluid's pressure. This is essential in systems where fluid needs to be moved against gravity or through long pipes. On the other hand, turbines extract energy from a fluid, often for generating electricity or performing mechanical work, leading to a drop in pressure within the fluid system.

Examples & Analogies

Think of a bicycle pump. When you use the pump, you are pushing air into a tire, increasing its pressure. Similarly, when water flows through a dam, the turbines spin and generate electricity, transforming the kinetic energy of the flowing water into mechanical energy. This process can be likened to a windmill converting the kinetic energy of the wind into usable power.

Energy Conservation in Pump and Turbine Systems

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Pressure itself is not a form of energy; it is just a flow energy or storage potential energy per unit volume. Using Bernoulli's equation, we can differentiate between the energy states in a fluid system.

Detailed Explanation

Pressure in fluid systems represents potential energy per unit volume rather than energy in its raw form. By applying Bernoulli's equation, which incorporates pressure, kinetic energy, and elevation, we can analyze how energy transforms between these states as fluid moves through pipes. For example, as a pump increases the pressure of water, some potential energy is converted into kinetic energy, allowing the water to flow effectively through pipes.

Examples & Analogies

Imagine a water slide at a park. At the top of the slide, water is stored at a high elevation (potential energy). When you slide down, it converts to kinetic energy, allowing you to zoom down. Similarly, in pumping systems, energy switches forms but remains consistent through the transition.

Understanding Mechanical Energy Losses

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Mechanical energy losses due to frictional effects cause the energy gradient line and hydraulic gradient line to slope downwards in the direction of flow.

Detailed Explanation

As fluid travels through pipes, it encounters resistance from the pipe walls and other imperfections, leading to energy losses. This phenomenon is observed as a downward slope in both the energy and hydraulic gradient lines, illustrating that energy is spent on overcoming this friction. It highlights the importance of considering friction and other losses when designing fluid systems.

Examples & Analogies

Imagine sliding down a sandpaper slide instead of a smooth one. The rough surface creates friction that slows you down, much like how water slows as it flows through a pipe. This friction reduces the energy available for doing work, like turning a turbine or reaching a faucet.

Efficiency in Pump and Turbine Systems

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The efficiency of pumps and turbines can be defined in terms of the ratio of output power to input power, taking into account energy losses.

Detailed Explanation

Efficiency measures how well a system converts input energy into useful output, making it critical in designing effective pumps and turbines. A pump that operates with high efficiency ensures that most of the mechanical energy is converted into hydraulic energy without significant losses. Similarly, for turbines, efficiency indicates how effectively they can convert the energy of flowing fluid into mechanical energy. Understanding and optimizing for efficiency helps reduce costs and increase the performance of fluid systems.

Examples & Analogies

Consider a car engine. If it burns fuel effectively, it converts most of that fuel's energy into motion, making the car efficient. Conversely, if too much energy is wasted as heat or noise, the engine is less efficient. Similarly, in fluid systems, we aim for high efficiency to save energy and resources.

Application of Bernoulli’s Equations in Fluid Systems

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The Bernoulli equation allows for the analysis of energy changes between various points in the flow, giving insight into pressure differences and flow rates.

Detailed Explanation

By using Bernoulli's equation, we can assess how the energy levels of fluid change when moving from one point to another within a system. This understanding is crucial for engineers when designing pipelines, pumps, and turbines, as it allows them to predict how fluid will behave under various conditions. By incorporating parameters like elevation, velocity, and pressure, engineers can optimize systems to ensure they work efficiently and effectively.

Examples & Analogies

Think of a roller coaster; the height and speed of the ride correlate with energy changes as it moves. Similarly, by looking at a specific point in a fluid system and applying Bernoulli's equation, we can determine how high (pressure) or fast (velocity) the fluid will be at different points, thus predicting system behavior.

Key Concepts

-

Pressure and Hydraulic Gradient Lines: In pipes, as fluid exits into the atmosphere, the pressure head becomes atmospheric, making the hydraulic gradient line coincide with the pipe outlet. The section explains mechanical energy losses due to friction, which affect the energy gradient line.

-

Energy and Mechanical Energy Losses: Mechanical energy is transferred to fluid through pumps, which increase pressure, while turbines extract mechanical energy by reducing pressure. The relationship between pressure and energy is explored using Bernoulli's equations.

-

Efficiency of Energy Systems: The efficiency of pumps and turbines is critical in determining the effectiveness of the energy transfer. Various losses—including heat and sound—reduce system efficiency, necessitating calculations for practical applications.

-

Example Problems: The section illustrates the application of mass conservation and Bernoulli equations through example problems, enabling students to calculate theoretical discharge, coefficient of discharge, and pressure differences in fluid flow scenarios.

-

By understanding the fundamentals of pump and turbine systems, students can resolve flow design issues effectively and analyze hydraulic structures.

Examples & Applications

Example of a pump enhancing water pressure in a system.

Scenario of a turbine in a hydropower project converting fluid energy to electrical energy.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Pumps make flow rise, turbines take its size.

Stories

Imagine a farmer using a pump to draw water from a well, making the pressure rise to water the crops, while a turbine by a river harnesses the water flow to generate electricity.

Memory Tools

PETS: Pumps Energize, Turbines Siphon.

Acronyms

HPE

Hydraulic

Pressure

Energy.

Flash Cards

Glossary

- Hydraulic Gradient Line

Represents the hydraulic grade or energy level in a fluid system where pressure head equals atmospheric pressure at the fluid surface.

- Energy Gradient Line

Indicates the total energy available in the fluid flow accounting for potential energy, kinetic energy, and pressure energy.

- Pump

A device that transfers mechanical energy to a fluid, increasing its pressure and flow rate.

- Turbine

A device that extracts mechanical energy from a fluid flow, typically resulting in a reduction of the fluid pressure.

- Efficiency

The ratio of useful output energy to the input energy, often expressed as a percentage, indicating how well energy is converted within a system.

Reference links

Supplementary resources to enhance your learning experience.