Application of Bernoulli's and Momentum Equations

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Bernoulli's Equation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will begin our discussion with Bernoulli’s equation. Can anyone tell me what the fundamental principle of Bernoulli's equation is?

Is it about the conservation of energy in fluid flow?

Exactly! Bernoulli’s equation relates the pressure, velocity, and elevation in a moving fluid, encapsulating the idea of energy conservation. Remember the acronym PEK for Pressure, Elevation, and Kinetic energy.

How does this apply to our pipes?

Great question! In pipes, we often analyze the flow and determine energy losses due to factors like friction and fittings.

What about the Reynolds number?

The Reynolds number helps us determine the flow regime: laminar or turbulent, which directly affects our calculations of energy losses.

Can we use Bernoulli’s equation in turbulent flow?

Yes, but with adjustments, and we must consider friction losses. Let’s explore that further!

Major and Minor Losses in Fluid Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand Bernoulli's equation, let’s discuss major and minor losses. Who can explain the difference?

I think major losses are due to friction in long stretches of pipe?

Correct! Major losses primarily arise from friction. Minor losses, however, occur due to fittings like bends or valves.

How can we calculate these losses?

We utilize specific loss coefficients, K values, which are often determined experimentally. Energy loss can be calculated using the formula: hL = K * (v^2 / 2g).

What kind of setups do we use for this experimentation?

Typically, setups involving manometers to measure pressure differences at various points along the pipe help in quantifying these losses.

Got it! So, Bernoulli's allows us to see how energy behaves in the flow.

Exactly! Understanding these concepts helps engineers design better pipe systems with minimal losses.

The Role of Reynolds Number

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive deeper into Reynolds number. Can anyone tell me its significance?

It indicates whether the flow is laminar or turbulent, right?

Exactly! A Reynolds number below 2300 indicates laminar flow, while above 4000 indicates turbulent flow.

What happens in the transition range?

Great question! In the range of 2300 to 4000, the flow can be unpredictable, which makes calculations for friction factors complex.

How do we compute friction factors?

We often refer to Moody's chart for that! It relates friction factor, Reynolds number, and relative roughness.

So, if we have a rough pipe, does it change the friction factor?

Yes! In turbulent flow, after a certain roughness, the friction factor becomes independent of Reynolds number and depends only on the roughness itself.

This understanding makes it easier for practical applications!

Absolutely, this knowledge is crucial for effective pipe design!

Minor Losses and Practical Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s explore minor losses in terms of practical applications. Can anyone share what types of fittings might cause minor losses?

Bends, elbows, and valves?

Exactly! Minor losses occur at fittings and transitions. These can be quantified using specific loss coefficients.

So, do we calculate those separately?

Correct! Each fitting has a K value, which helps us calculate the additional energy loss.

What are common values we can refer to for these fittings?

There are tables available that list K values for different fittings based on experimental data! They serve as great references.

And these calculations help in optimizing designs?

Exactly! By minimizing energy losses, engineers can design more efficient systems.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section provides insights into how Bernoulli's and momentum equations can be utilized to understand the behavior of fluid flow through pipes, highlighting energy losses, the significance of Reynolds number, and methodologies for calculating friction factors and minor losses in pipe systems.

Detailed

Detailed Summary

The application of Bernoulli’s and momentum equations plays a pivotal role in the study of fluid mechanics, particularly in understanding viscous flow through pipes. This section elaborates on the importance of these equations in analyzing pipe systems, especially when evaluating energy losses due to friction, fittings, and changes in diameter.

Key concepts introduced include the relationship between Reynolds number and flow behavior, distinguishing between laminar and turbulent flow, and identifying how energy losses can be quantitatively assessed using experimental approaches and theoretical foundations. The section also emphasizes the significance of understanding minor losses that occur at bends, fittings, and contractions in pipes alongside major losses caused by friction.

Moreover, the Moody's chart for calculating friction factors based on Reynolds number and relative roughness is highlighted, providing practical tools for engineers to design efficient fluid transport systems. Experimental setups that measure pressure differences and fluid flows serve as the basis for practical applications, offering a bridge between theoretical concepts and engineering practice.

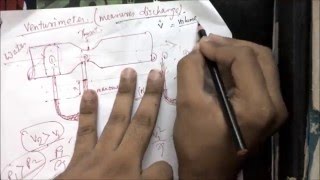

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Pipe Flow Applications

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fluid Mechanics

Prof. Subashisa Dutta

Department of Civil Engineering

Indian Institute of Technology-Guwahati

Lecture - 22

Losses in Pipe Fittings

Welcome all of you again for the second lectures on viscous flow through pipes, which is quite interesting for you if you are preparing for GATE or engineering service. So this part of the lectures if you see that is quite interesting in the sense that it has the applications of Bernoulli’s equations.

It has a applications of momentum equations. Also it has that how to approximate a complex flow through the pipe systems. So that way I designed this course for you so that you can have the feeling of application studies how we can do it with knowledge of the fluid mechanics.

Detailed Explanation

This chunk introduces the concept of viscous flow in pipes, emphasizing its relevance for students preparing for engineering entrance examinations. The instructor outlines the focus on applying Bernoulli’s and momentum equations, which are essential to analyzing fluid mechanics in real-world scenarios. The aim is to provide students with practical knowledge that they can utilize in engineering applications.

Examples & Analogies

Think about how water flows through a garden hose. When you squeeze the end of the hose, the water shoots out with more force. This is similar to applying Bernoulli’s equation, as it helps us understand how pressure (applied by squeezing) affects the velocity of the water. Similarly, understanding these concepts in this lecture will aid you in various engineering projects like plumbing or irrigation designs.

Turbulent Flow in Pipes

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Again I am repeating these slides to just to energize to you that when you have the pipe flow, most of the times we have the turbulent flow okay. So whatever the pipe flow you consider it always we have the turbulent flow as you can visualize the turbulent flow of high turbulence, low turbulence zones, high turbulence, and the low turbulence zones.

When you talk about the turbulence, do not look at the figures like these type of vortex phenomena and all. Always we quantify the turbulence with respect to Reynolds numbers. The Reynolds numbers, if it is a greater than some threshold values then we call the turbulent flow.

Detailed Explanation

This chunk discusses the characteristics of turbulent flow in pipes, highlighting that most pipe flows are turbulent rather than laminar. It introduces the concept of Reynolds numbers, which help classify flow regimes based on the ratio of inertial forces to viscous forces. The instructor notes specific thresholds: Reynolds number below 2300 indicates laminar flow, while above 4000 indicates turbulent flow, with transitional states in between.

Examples & Analogies

Imagine stirring a cup of coffee. If you stir slowly, the motion is smooth and orderly (laminar); however, if you stir rapidly, the coffee tumbles chaotically (turbulent). Similar to how stirring imparts energy to the coffee, understanding how turbulent flow works in pipes helps engineers design systems that can manage these chaotic fluid behaviors effectively.

Understanding Energy Losses in Pipe Systems

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

On the next slides what I am showing it that how we conduct the experiments to quantify the how much of losses are happening, energy losses is happening it. So one if you look it, we call major losses. Major losses, that is the losses due to the frictions. So that way if you look it there are the two pipes are there. And in these two different pipes there are the manometers are attached to determine what is the pressure difference at the two points.

Detailed Explanation

This chunk explains the experimental setup used to measure energy losses in pipe systems, differentiating between major losses (friction losses) and minor losses (due to fittings, bends, etc.). By attaching manometers to measure pressure differences, students learn how to quantify these losses, which are crucial for understanding the efficiency of pipe systems. Bernoulli’s equation with modifications can help calculate these losses based on the pressure drop observed.

Examples & Analogies

Think of a car driving on a bumpy road. The bumps cause the car to use more fuel (losing energy) to maintain speed. Similarly, in a pipe, friction and bends versus smooth straight sections affect how easily water flows, demonstrating how engineers must analyze these factors to keep plumbing systems efficient.

Applications of Bernoulli's Equation

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now let us go back to the Lewis Moody 1944 Princeton University, USA. What he has developed is from the experimental data. If you try to look it, he has not pulled out only his experimental data, but long back the data from others researchers. All the data he combined it for the developing this Moody's charts to compute friction factors, compute the friction factor, the flow through the pipes.

Detailed Explanation

This chunk discusses the significance of Moody's chart, which is a crucial tool in fluid mechanics for determining friction factors in various flow conditions. It emphasizes how these charts compile extensive data from multiple sources to help engineers predict flow behavior in pipes. Understanding friction factors is essential for calculating energy losses in pipe systems accurately.

Examples & Analogies

Imagine using a cookbook that combines recipes from many chefs. Just like that cookbook helps you find the best way to prepare a meal, Moody's chart helps engineers find the best way to estimate how much energy is lost in a pipe due to friction, making sure that water flows effectively through the systems they design.

Minor Losses in Pipe Systems

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now let us go to the minor losses in the pipe systems. As I told it when you have the pipes, it can have a regions you have a smaller pipe to bigger pipe or bigger pipe to the smaller pipe. When you have a these conditions that means the flow is coming it here and going out, the smaller diameters and the larger diameter.

Detailed Explanation

This chunk highlights the concept of minor losses occurring during fluid flow through changes in pipe diameter and other fittings. It mentions how these losses can significantly affect overall energy efficiency in a pipe system, leading to additional considerations when designing plumbing and distribution systems.

Examples & Analogies

Think of a garden hose that narrows near the nozzle. The pressure and flow of water change as it passes through the smaller section, causing friction and energy loss. Just like in engineering, where every fitting and size change affects performance, your hose’s structure influences how much water reaches your plants.

Key Concepts

-

Bernoulli's Principle: A fundamental principle relating pressure, velocity, and elevation in fluid dynamics.

-

Reynolds Number: A dimensionless value that predicts flow behavior, distinguishing between laminar and turbulent flow.

-

Friction Factors: Measure of resistance to fluid flow in pipes, varying with Reynolds number and roughness.

-

Major and Minor Losses: Energy losses in fluid systems due to friction and fittings respectively.

Examples & Applications

In a water supply system, the pressure drop across a pipe system can be analyzed using Bernoulli’s equation to determine pumping requirements.

Using Moody's chart, an engineer can find the friction factor for a given Reynolds number to calculate energy losses in a rough pipe.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If the flow is steady and pressure's a must, Bernoulli’s Equation you can trust.

Stories

Imagine a water slide where a ball zips down effortlessly. At the top, it has high potential energy, but as it slides down, that energy converts to speed, illustrating Bernoulli's principle in action!

Memory Tools

Remember PEK (Pressure, Elevation, Kinetic) for Bernoulli's key elements.

Acronyms

Use M&M to recall Major and Minor losses in fluid systems.

Flash Cards

Glossary

- Bernoulli’s Equation

An equation describing the conservation of energy in fluid flow, relating pressure, velocity, and elevation.

- Reynolds Number

A dimensionless number used to predict flow patterns in different fluid flow situations.

- Friction Factor

A dimensionless quantity used to describe the resistance to flow in a pipe due to friction.

- Minor Losses

Energy losses in a fluid flow due to fittings and other components like bends and valves.

- Moody's Chart

A graphical representation that relates friction factors, Reynolds number, and relative roughness for different flow conditions.

Reference links

Supplementary resources to enhance your learning experience.