Application of Streamlines in Fluid Flow

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Streamlines and Flow Types

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome everyone! Let's start our discussion by talking about streamlines. Can anyone tell me what a streamline is?

Isn't it a line that represents fluid flow?

Exactly! Streamlines show the path that fluid particles follow. Now, why do we care about these in fluid mechanics?

Because they help us visualize how the fluid moves?

Right! Streamlines are crucial when applying Bernoulli's equations. Can anyone recall the significance of the Reynolds number?

It helps classify flows into laminar and turbulent!

Correct! Below 2300 is laminar, above 4000 is turbulent. What happens in between?

It's transitional flow, where it can vary between the two types!

Great summary! Understanding these concepts will help us analyze energy losses in various pipe systems effectively.

Energy Losses in Pipe Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, who can explain what we mean by energy losses in pipe systems?

Is it the energy wasted due to friction and fittings like valves and bends?

Yes! These are categorized as major and minor losses. Major losses are due to friction along the length of the pipe. What about minor losses?

Those are from fittings, bends, and changes in diameter?

Exactly! Do you recall how we can calculate these losses using Bernoulli’s or momentum equations?

We can measure pressures at different points and apply those equations!

That's right! And don't forget the importance of proper piping design to minimize these losses.

Practical Applications of Streamlines

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's think about a practical scenario. How do we apply what we've learned about streamlines to a water distribution system?

We’d look at how water flows from a reservoir to various homes, right?

Yes! We need to account for losses due to pipe fittings. Why is it important to minimize these losses?

To ensure that there's enough pressure and flow at the destination!

Exactly! By understanding how fluid dynamics work, we can design an efficient system. How might we measure this in a laboratory setting?

By setting up experiments with manometers to measure pressure differences and flow rates.

Well said! Remember that accurately measuring and analyzing these factors helps inform better engineering decisions.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

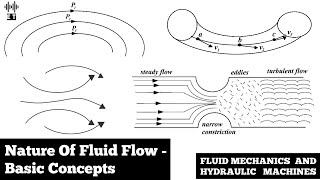

Key concepts in this section include the visualization of turbulent flow via streamlines, the significance of Reynolds number in classifying flow types, and the analytical methods used for calculating energy losses in pipe fittings through Bernoulli’s equations and momentum considerations.

Detailed

Application of Streamlines in Fluid Flow

In fluid mechanics, streamlines are essential for visualizing and analyzing fluid motion. They represent the trajectory that fluid particles follow and are vital in the application of Bernoulli’s equations and in loss calculations in pipe systems. Understanding the distinctions between laminar and turbulent flow via the Reynolds number allows engineers to classify flows and apply appropriate equations. For instance, a Reynolds number below 2300 indicates laminar flow, while a value above 4000 signifies turbulent flow, with a transition region in between.

The section further emphasizes how streamlines help in understanding complex flows, with examples illustrating energy losses in pipe fittings and the significance of smooth transitions in varying pipe configurations. Experimental setups also play a crucial role in quantifying losses due to factors such as friction in pipe fittings, bends, valves, and contractions/expansions in pipe diameter.

Youtube Videos

![Streamline Animation [Fluid Mechanics]](https://img.youtube.com/vi/liNA14aPl2s/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Streamlines

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Streamlines are critical for analyzing fluid flow. They visualize how fluid particles move over time and help simplify complex flow problems. When analyzing fluid dynamics, you should apply Bernoulli's equations along these streamlines, ensuring flows are considered irrotational.

Detailed Explanation

Streamlines illustrate the paths that fluid particles follow in the flow. When fluid flows smoothly and predictably, analyzing it along these lines can simplify complex calculations. Bernoulli's principles help determine the relationships between velocity, pressure, and elevation at different points along these lines. The assumption of irrotational flow implies that there’s minimal disruption to the flow paths, making calculations more manageable.

Examples & Analogies

Think of streamlines like the lines on a subway map. Each line represents a pathway for the subway cars (fluid particles) to travel. Just as the subway map helps passengers understand their journey, streamlines help engineers analyze fluid movement.

Vortex Formation and Energy Losses

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In fluid systems, bends and fittings can cause vortices to form, leading to energy losses. Energy losses arise from the chaotic motion of fluids as they navigate through these bends. The angle and configuration of bends affect the severity of vortices and energy dissipation.

Detailed Explanation

When fluid flows through bends in pipes, it can create regions where the flow circulates in a chaotic manner, known as vortices. These vortices disrupt the smooth flow of the fluid, leading to increased resistance and energy loss. The design of the pipe (for instance, whether it has sharp 90-degree angles or smooth curves) significantly impacts how much energy is lost in these transitions. A well-placed curve can significantly decrease energy loss compared to a sharp bend.

Examples & Analogies

Imagine driving a car at a high speed around a tight corner. The sharper the turn, the more difficult it is to maintain speed due to the force exerted against the car’s motion. Similarly, in fluid flow, sharp bends create resistance that slows down the fluid and wastes energy.

Minor Losses in Pipe Systems

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Minor losses occur due to fittings or components in the pipe system, such as valves, bends, and expansions. These fittings introduce additional turbulence and pressure drops which contribute to overall energy losses in the system.

Detailed Explanation

In addition to friction losses along the length of pipes, minor losses arise from fittings and alterations in the flow path, including expansions and contractions. Each component can disrupt the flow and lead to energy losses due to turbulence and pressure changes. Understanding and calculating these losses ensure designers can minimize energy use in fluid systems.

Examples & Analogies

Consider a garden hose. If you were to connect multiple fittings or even a spray nozzle, you would feel a decrease in water pressure compared to a straight and unobstructed hose. Each fitting introduces minor disturbances and losses, much like how bends and valves do in a larger pipe network.

Applying Bernoulli’s Equation and Control Volume Analysis

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When applying Bernoulli’s equation in fluid dynamics, it is crucial to choose the right control volume where the flow can be considered steady and predictable. This involves ensuring that streamlines are parallel and that the control volume encompasses sections without significant disturbances.

Detailed Explanation

Bernoulli's equation helps relate the velocity, pressure, and elevation of fluid in motion, but it must be applied correctly. Selecting a control volume – a defined space through which the fluid flows – is essential to ensure the flow properties are constant across the region. The region should be free from sudden changes in velocity or pressure to maintain accuracy in calculations.

Examples & Analogies

Imagine using a measuring cup to pour water at a steady rate. If you pour directly into a container, the measure will accurately reflect the volume dispensed. If you were to pour into a container with a large opening and many disturbances, your measurements would vary significantly. Similarly, choosing the right control volume guarantees precise application of Bernoulli's principles.

Key Concepts

-

Streamlines: Essential for visualizing fluid flow, providing insight into the velocity and direction of fluid particles.

-

Reynolds Number: A fundamental parameter that helps classify flow types, essential for applying the correct equations in fluid dynamics.

-

Bernoulli’s Equation: A key formula that describes the conservation of mechanical energy in fluid flow, necessary for calculating losses in pipes.

-

Energy Losses: Recognizes the importance of accounting for both major and minor losses during fluid transportation, affecting system performance.

Examples & Applications

Example 1: A water supply system where calculations of energy losses due to pipe fittings are essential for maintaining adequate pressure at user points.

Example 2: Using Reynolds number to determine whether to use laminar or turbulent flow equations in designing a new piping system.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When the flow is calm and nice, Under 2300, it’s like rolling dice. Over 4000, things get loud, Turbulence is here, it’s a wild crowd.

Stories

Imagine a smooth river. Below 2300, the water flows gently, like a peaceful stream. As it speeds up and over 4000, the water becomes a chaotic froth, bouncing around likes wild kids at a playground.

Memory Tools

Remember the saying: ‘Low means slow, High makes it fly!’ for understanding laminar (low) vs. turbulent (high) flow.

Acronyms

Remember 'SLANT' for understanding flow characteristics

S-streamlines

L-laminar

A-application

N-navigating

and T-turbulent.

Flash Cards

Glossary

- Streamline

A line that follows the flow of fluid particles, indicating their direction and speed at a given time.

- Reynolds Number

A dimensionless number used to predict the flow regime, indicating whether flow is laminar or turbulent based on the ratio of inertial to viscous forces.

- Bernoulli's Equation

An equation that relates the pressure, velocity, and height of a fluid to describe energy conservation in flow.

- Energy Losses

Losses in mechanical energy as fluid moves through a system, attributed to factors like friction and turbulence.

- Pipe Fitting

A component in piping systems used to connect different parts, including elbows, valves, and tees.

- Turbulent Flow

Flow characterized by chaotic fluid motion, typically occurring at high velocities and Reynolds numbers.

- Laminar Flow

A smooth, orderly flow where fluid moves in parallel layers, typically occurring at low velocities.

Reference links

Supplementary resources to enhance your learning experience.