Fluid Mechanics

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Turbulent Flow and Reynolds Number

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start with turbulent flow. Can any of you explain what Reynolds number signifies in fluid mechanics?

Isn't it the ratio of inertia forces to viscous forces?

Correct! To remember - think of it as I for Inertia and V for Viscosity, giving us the 'IV Ratio'. When Reynolds number is less than 2300, flows are laminar, above 4000, they become turbulent.

What happens in between these numbers?

Great question! This is the transition zone, where flow characteristics fluctuate. Always analyze based on the flow type to determine corresponding energy loss parameters.

So, turbulent flow causes more energy loss?

Exactly! Higher turbulence leads to increased friction and energy loss. Let’s summarize: Reynolds numbers under 2300 indicate laminar flow, while above 4000 indicates turbulent flow.

Energy Loss in Pipe Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, can someone explain what major and minor losses mean?

Major losses are those from friction in the pipe, while minor losses occur due to fittings and bends, right?

Exactly! A helpful way to remember: think 'Main Friction' for Major and 'Minor Bends' for Minor. Pressure differences can help us quantify these losses using Bernoulli's equation.

How do we calculate these losses?

We measure pressure at different points and can compute velocity, using that in Bernoulli's equation to find energy loss. Always calculate systematically.

What practical applications exists for this?

Excellent question! Real-world water supply systems need to minimize energy losses for efficient design. Let’s summarize: Major and minor losses come from different sources, and pressure measurements lead to quantifying energy losses.

Conducting Experiments on Pipe Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will see how experiments can help us quantify losses. Can anyone suggest how we might set up such an experiment?

We can connect manometers to measure pressure at different points in a pipe?

Absolutely! Observing pressure differences gives us critical data. Bring in a virtual fluid ball concept to visualize how flow interacts with the walls of the pipe.

So we're using these fluid balls to understand the distribution of energy loss?

Exactly! By visualizing it that way, we can better understand the mixing and vortex formations which contribute to energy loss. Summing up: Experiments with manometers yield insightful data on energy losses.

Design Considerations in Pipe Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

When designing pipe systems, what factors should we consider to minimize energy loss?

The diameter of the pipes and the type of fittings used, right?

Exactly! You want wider pipes to reduce velocity and friction. Consider the fittings’ angles. Remember, smoother transitions reduce turbulence.

What about vertical tanks in a water supply scheme?

Good spot! Proper positioning and dimension of tanks can aid in energy efficiency. Summarizing: Wider pipes and smooth fittings lead to less energy loss.

Application of Bernoulli’s Equation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss how Bernoulli’s Equation applies to our earlier discussions.

We use it to calculate energy loss, right?

Exactly! This equation will help you account for energy due to height, pressure, and velocity. It summarizes the conservation of energy principle in fluid dynamics.

Are there any limitations to using Bernoulli’s equation?

Yes, it applies ideally to incompressible, non-viscous fluids. Remember that! Summarizing, Bernoulli's provides needed theoretical framework but be mindful of its practical limits.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we delve into Fluid Mechanics, emphasizing the analysis of losses in pipe fittings. The segment discusses critical concepts including turbulent flow, Reynolds number thresholds, minor and major losses, and the practical implications of these in fluid system design. Students will engage with experimental setups and apply theoretical equations to real-world problems.

Detailed

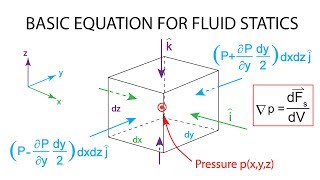

Fluid Mechanics

Fluid Mechanics examines the behavior of fluids in motion and at rest. This section focuses on the analysis of energy losses in pipe fittings — an essential consideration in civil engineering and fluid system design.

- Turbulent Flow and Reynolds Number: The section begins with a discussion on flow types governed by Reynolds numbers. Laminar flow occurs at Reynolds numbers below 2300, while turbulent flow is observed above 4000. Transitional flow lies between these thresholds. Understanding this concept is crucial for analyzing energy losses due to friction.

- Energy Loss Analysis in Pipe Systems: Major losses in pipe systems are primarily due to friction, while minor losses occur from pipe fittings and changes in flow direction or area. The lecturer highlights the significance of measuring pressure differences and how this relates to energy loss calculations using Bernoulli’s equation.

- Practical Applications: A significant focus is laid on the practical application to water supply systems, detailing how to model and calculate energy losses to optimize design. Students will learn to use computational tools alongside experimental results to determine the dimensions and configurations of pipe networks effectively.

- Study of Minor Losses: The course discusses configuring pipes with bends and elbows, emphasizing how these fittings introduce additional energy losses because of vortex formation.

In conclusion, a solid grasp of these fluid mechanics principles is critical for engineering successful fluid transport systems. The section prepares students for higher-level applications in civil and environmental engineering.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Fluid Mechanics

Chapter 1 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fluid Mechanics Prof. Subashisa Dutta Department of Civil Engineering Indian Institute of Technology-Guwahati Lecture - 22 Losses in Pipe Fittings Welcome all of you again for the second lectures on viscous flow through pipes, which is quite interesting for you if you are preparing for GATE or engineering service. So this part of the lectures if you see that is quite interesting in the sense that it has the applications of Bernoulli’s equations.

Detailed Explanation

This introduction emphasizes the importance of fluid mechanics, especially in applications related to pipe flow. Viscous flow is a common occurrence in engineering contexts, particularly for students intending to take exams like the GATE. The lecturer mentions the application of Bernoulli’s equation, which relates the pressure, velocity, and height in a fluid flow, indicating how critical fluid mechanics is in practical scenarios.

Examples & Analogies

Imagine trying to measure the pressure of water flowing through a hose in your garden. Just like you would use a gauge to understand how much pressure is needed to maintain a steady flow for watering the plants, engineers use fluid mechanics principles to analyze and design pipe systems in buildings and industrial setups.

Revisiting Pipe Flow

Chapter 2 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Today what I am talking about that we are going for a demonstrations of the pipe fitting experimental setups which is there in IIT Guwahati. Again, I will revisit the virtual fluid balls.

Detailed Explanation

The speaker introduces forthcoming demonstrations related to experimental setups for pipe fittings, which will help students understand real-world applications of the theories taught. Revisiting the concept of 'virtual fluid balls' suggests a visualization technique for pupils to grasp fluid behavior in pipes, where these imaginary particles represent fluid elements flowing through the system.

Examples & Analogies

Think about how you can visualize a crowd of people moving through a hallway. If they are flowing smoothly, you imagine them as smooth balls rolling along. However, if the crowd encounters a bottleneck, they might bunch up or create eddies. Similarly, virtual fluid balls help visualize the behavior of fluid flow through various pipe configurations.

Turbulent vs Laminar Flow

Chapter 3 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When you have the pipe flow, most of the times we have the turbulent flow. The Reynolds numbers, if it is a greater than some threshold values then we call the turbulent flow.

Detailed Explanation

The distinction between turbulent flow and laminar flow is crucial in fluid dynamics. Turbulent flow occurs when the Reynolds number exceeds a certain threshold, causing chaotic fluctuations in the flow. In contrast, a laminar flow has a Reynolds number below 2300, characterized by smooth and orderly layers of fluid. Understanding where each type occurs helps in predicting fluid behavior in various engineering applications.

Examples & Analogies

Picture a river flowing gently in some parts (laminar flow), where the water moves smoothly without disturbance. In contrast, imagine a rapids section (turbulent flow), where the water churns chaotically as it crashes over rocks. This analogy helps illustrate how flow conditions can change dramatically based on speed and surface conditions.

Energy Losses in Pipe Systems

Chapter 4 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When you look at the water supply systems, we need to know how much of loss is happening it. How much of pumping is the requirement is there.

Detailed Explanation

Analyzing energy losses in pipe systems is critical, particularly for water supply systems. Engineers must forecast how much energy (and thus money) is lost during the flow of water through pipes due to friction, bends, and fittings. By understanding these losses, they can optimize the design of the piping system for efficient and effective water delivery.

Examples & Analogies

Consider filling a bathtub with a garden hose. If you notice that the water flow decreases when you partially cover the hose with your hand, that's an example of energy loss caused by resistance at the constriction. Engineers work to minimize these types of losses in large-scale systems to ensure efficient water use in urban infrastructure.

Minor and Major Losses

Chapter 5 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Major losses are due to frictions. Minor losses like bends and valves also impact energy losses.

Detailed Explanation

In fluid dynamics, losses during flow can be categorized into major and minor losses. Major losses generally arise from friction in long stretches of pipes, while minor losses occur at fittings, bends, or valves. Understanding both is essential for predicting how much energy will be required for pumps and ensuring an efficient design.

Examples & Analogies

Think about how difficult it is to push a large box across a rough floor (major loss due to friction). Now imagine trying to slide the same box through a narrow doorway (minor loss due to a fitting). Both scenarios demonstrate that different components and features can create varying degrees of resistance that affect overall efficiency.

Virtual Fluid Balls and Streamlines

Chapter 6 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Understanding how the vortex formations happens within a pipe flow systems, when you consider the pipe, a horizontal pipes and because of the turbulence how the eddies formations happen.

Detailed Explanation

The concept of virtual fluid balls is used to explore the motion of fluids in various flow conditions, helping visualize the turbulent patterns that arise, such as eddies and vortices. Understanding these flow phenomena is crucial when predicting how fluid behaves under different scenarios in piping systems where flow changes can happen frequently.

Examples & Analogies

Imagine tossing a marble into a pool of water. As it sinks, it creates ripples and eddies, illustrating the turbulence effects. In engineering, similar principles apply as fluid balls help engineers map out how pressure and flow change within a pipe, much like observing the water’s behavior with the marble.

The Importance of Moody's Charts

Chapter 7 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Moody's charts help in computing friction factors, a critical component for determining energy losses in pipes.

Detailed Explanation

Moody's charts are a vital resource in fluid mechanics that allow engineers to calculate friction factors based on Reynolds number and pipe roughness. These charts provide a visual means of determining how friction losses change under different conditions, which can be crucial in designing efficient piping systems.

Examples & Analogies

Consider a blender mixing different ingredients – the smoother the sides of the jar, the less effort it takes to blend. Moody's charts help visualize how various factors (like pipe smoothness) impact energy loss, helping engineers determine the most efficient surfaces for piping designs.

Key Concepts

-

Reynolds Number: Indicates flow type (laminar or turbulent), critical for calculating energy losses.

-

Bernoulli's Equation: Establishes the relationship between pressure, velocity, and height.

-

Major vs. Minor Losses: Key considerations in calculating energy lost in fluid systems.

Examples & Applications

Using a manometer to measure pressure differences in a pipe to quantify energy loss due to friction.

Calculating the energy loss in a water distribution system with varying pipe diameters and fittings.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In flows that swirl and twirl so fast, the Reynolds shows if that will last.

Stories

Imagine two rivers: the calm laminar one flows smoothly, while the turbulent river has waves crashing everywhere, akin to energy loss.

Memory Tools

Remember 'V' for viscosity, 'I' for inertia to recall the Reynolds number.

Acronyms

M&M for Major and Minor losses in pipes.

Flash Cards

Glossary

- Reynolds Number

A dimensionless quantity used to predict flow patterns in different fluid flow situations. An indicator of whether flow is laminar or turbulent.

- Bernoulli's Equation

A principle of fluid dynamics that provides a relationship between pressure, velocity, and height in fluid flow.

- Major Losses

Energy losses in a fluid system primarily due to friction with the flow through pipes.

- Minor Losses

Energy losses that occur due to fittings, bends, and valves in the pipe system.

- Turbulent Flow

Flow characterized by chaotic changes in pressure and flow velocity, usually occurring at Reynolds numbers above 4000.

- Laminar Flow

Flow in which fluid moves in smooth, parallel layers, occurring at Reynolds numbers below 2300.

- Vortex

A region in a fluid where the flow revolves around an axis line, commonly found in bends or in fluid mixing zones.

Reference links

Supplementary resources to enhance your learning experience.