Importance of Energy Losses in Systems

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Energy Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss the energy losses that occur in fluid systems, specifically within pipes. Can anyone tell me why understanding these losses is important?

Is it because they can affect the efficiency of the system?

Exactly! Energy losses can impact how efficiently a fluid flows through a system, and even how much energy we require to operate pumps. Now, what do you think major losses are?

Are those the losses from friction in the pipes?

That's right! Major losses come mainly from friction between the fluid and the pipe walls. Minor losses come from things like fittings or bends in the pipe. Can anyone think of an example of a minor loss?

Maybe the energy lost at a bend?

Correct! Bends and fittings can create turbulence, increasing energy loss. Great participation, everyone! To summarize, understanding these losses allows engineers to design better, more efficient systems.

Reynolds Number and Flow Regimes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about the Reynolds number. Can anyone remind me what it is and its significance in fluid flow?

I think it measures the ratio of inertial forces to viscous forces.

Exactly! It helps us determine if the flow is laminar or turbulent. If Re is less than 2300, we have laminar flow; greater than 4000 indicates turbulent flow. Can anyone explain why this matters for energy losses?

Turbulent flow usually has higher energy losses because it's more chaotic and creates more friction.

Yes! Turbulent flows exhibit higher energy losses, and thus knowing which regime you are in is crucial for calculations. Remember this relationship!

Practical Applications in Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s connect what we’ve learned to real-world applications. Why should engineers care about minimizing energy losses?

To reduce costs and improve system efficiency!

Absolutely! Efficient designs can save on energy and maintenance costs. Can anyone think of a system where this knowledge is critical?

Water supply systems come to mind. We want to ensure enough pressure at the tap.

Correct, and in designing these systems, engineers use software to calculate expected losses. This reflects the importance of understanding both major and minor losses.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the significance of energy losses in pipe systems, highlighting major and minor losses due to friction, fittings, and other factors. Understanding these losses is crucial for optimizing fluid flow and ensuring efficient engineering design.

Detailed

Importance of Energy Losses in Systems

Energy losses in fluid systems, particularly within pipes, are vital for engineers to comprehend. These losses can have significant impacts on the design, efficiency, and cost-effectiveness of systems such as water supply networks. In fluid mechanics, losses are classified into major losses (primarily caused by friction) and minor losses (resulting from fittings and other obstructions).

Key Points:

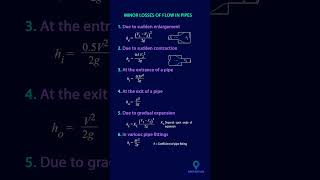

- Major Losses vs. Minor Losses: Major losses arise mainly from friction between the fluid and the pipe wall, while minor losses occur at fittings, bends, valves, and other components. Identifying both types of losses is essential to calculate the overall energy loss in a system accurately.

- Reynolds Number's Role: The flow regime (laminar or turbulent) plays a key role in determining energy losses, which can be estimated using Reynolds numbers.

- Tools for Analysis: Engineers rely on methods such as Bernoulli’s equation and Moody’s chart to assess energy losses effectively.

- Applications in Civil Engineering: Properly designing and analyzing pipe systems can save costs and improve system performance, especially in applications like water supply engineering.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Energy Losses in Pipe Systems

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When designing water supply systems, understanding energy losses is crucial. These losses occur due to friction and turbulence as fluid flows through pipes, fittings, and valves.

Detailed Explanation

In any fluid flow scenario, especially in pipeline systems, energy is lost mainly due to friction against the walls of the pipes and due to turbulence in the fluid itself. When designing a water supply system, engineers must account for these energy losses to ensure that there is enough energy (pressure) left in the system to reach consumers. This involves calculations to determine how much pumping energy is needed to overcome these losses and ensure optimal flow to the end-users.

Examples & Analogies

Consider trying to push water through a long garden hose. If the hose is very long or has kinks (representing friction loss), or if the water flows very fast creating waves (representing turbulence), you have to push much harder to get the water out than if the hose was straight and short. Similarly, engineers must factor in these losses in their designs.

Classification of Energy Losses: Major and Minor

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Energy losses in pipe systems can be classified as major losses due to friction and minor losses due to fittings and bends.

Detailed Explanation

Major losses are calculated based on the length of the pipe, its diameter, and the fluid's viscosity, primarily stemming from the friction between the fluid and the pipe walls. Minor losses occur due to fittings such as valves, elbows, and bends in the piping system. These fittings can cause additional turbulence and alter the flow, leading to further energy losses.

Examples & Analogies

Imagine you're pouring water through a funnel. The water moves smoothly through the wide opening of the funnel (major loss). But once it hits the narrow neck, it splashes and creates turbulence (minor loss). Each time the fluid encounters a fitting or change in direction, it can lose energy.

Quantifying Energy Losses

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Quantification of losses involves using pressure differences measured through manometers and applying Bernoulli’s equation to find out the amount of energy lost due to friction and fittings.

Detailed Explanation

To measure how much energy is lost within a pipe system, engineers can use instruments called manometers to observe the pressure at different points in the flow. By comparing these pressure readings and applying principles from Bernoulli’s equation, they can calculate how much energy has been lost due to friction and minor losses. This data is critical in ensuring that enough pressure is maintained throughout the system.

Examples & Analogies

Think of it like measuring how much fuel you use while driving. If you check your fuel gauge (analogous to measuring pressure) before and after a long trip, you can calculate how much fuel you lost. Similarly, engineers measure pressure at different points in a pipeline to see how much energy they've 'spent' overcoming friction and turbulence.

Practical Implications of Energy Losses

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Understanding energy losses helps engineers design efficient systems that minimize costs and maximize the performance of fluid transport.

Detailed Explanation

By knowing where and how energy is lost in a pipe system, engineers can make informed decisions about the type of pipes to use, the size of the pipes, and where to place pumps. This not only improves performance but also reduces operational costs, as less energy is wasted. Efficient designs can lead to lower electricity bills and extended lifespans for pumps and other components.

Examples & Analogies

Just like planning a road trip, knowing the routes with heavy traffic (energy losses) allows you to choose alternate paths that save gas and time. Engineers apply the same principle to fluid systems, ensuring a smooth flow that optimizes energy use and minimizes waste.

Key Concepts

-

Energy Losses: Losses occurring due to friction (major) and fittings/bends (minor) in fluid systems.

-

Reynolds Number: A key parameter in determining flow type and flow regime.

-

Major vs. Minor Losses: Understanding the differentiation is crucial for accurate engineering calculations.

Examples & Applications

When designing a municipal water supply system, engineers calculate the energy losses in the pipe to ensure proper pressure at water delivery points.

Using the Moody chart, engineers can estimate friction factors and thus energy losses in different types of pipes.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In pipes where flow is all fine, major losses come from friction over time.

Stories

Imagine a water system as a winding road. The bumps (fittings) slow the car (water), causing energy to be lost. Understanding these obstacles leads to a smoother ride.

Memory Tools

Remember 'FEMS' for Fluid Energy: Friction leads to Major loss, Fittings lead to Minor loss.

Acronyms

LTF

Laminar is Tranquil

Turbulent is Frictional.

Flash Cards

Glossary

- Major Losses

Energy losses primarily due to friction within the flow of a fluid through pipes.

- Minor Losses

Energy losses occurring due to fittings, bends, and other components in a piping system that disrupt flow.

- Reynolds Number

A dimensionless number used to predict flow patterns in different fluid flow situations.

- Turbulent Flow

Flow regime characterized by chaotic changes in pressure and flow velocity.

- Laminar Flow

Flow regime characterized by smooth and orderly fluid motion.

- Bernoulli’s Equation

An equation that describes the conservation of energy in flowing fluids.

Reference links

Supplementary resources to enhance your learning experience.