Flow Characteristics in Pipes

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Flow Types

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, let’s start by discussing the types of flow in pipes. Who can tell me the difference between laminar and turbulent flow?

Laminar flow is smooth and orderly, right? Like when you pour syrup.

Exactly! Laminar flow is characterized by Reynolds numbers less than 2300. What about turbulent flow?

Turbulent flow has chaotic changes in pressure and velocity, usually above 4000 Reynolds number.

Great! Remember, the Reynolds number is crucial because it helps us determine which flow we have.

What happens between those numbers?

Good question! That’s the transition flow—the behavior can vary. It's important for understanding how our systems may behave.

To remember: *Low Reynolds = Laminar; High Reynolds = Turbulent*. Keep this acronym in mind: LHT (Low High Turbulent).

Energy Losses in Pipes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about energy losses in pipes. Who can explain what major losses are?

Major losses come from friction, right? They occur in straight parts of the pipe.

Yes! Major losses are usually quantified using Bernoulli's equation. But we also need to account for minor losses. What might those be?

Those would be from bends, fittings, or valves!

Exactly! Minor losses can add up and are essential for accurate system design. Remember: *Fittings Fit Action* for minor losses.

What's the significance of measuring these losses in experiments, though?

Good question! These experiments help us develop accurate predictions of flow efficiency in real-world applications. Tracking energy loss ensures we design systems that minimize waste.

Application of Bernoulli’s Equation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

How does Bernoulli’s equation relate to energy losses in our calculations?

It helps to calculate pressure changes due to friction and other losses in the pipe.

Exactly! When we measure pressures before and after certain sections of the pipe, we can compute total energy loss effectively.

So, is it like tracking energy from the water source to our taps?

You got it! The goal is to ensure that enough energy is available at the end-user tap even after accounting for losses.

Is there a formula we should remember in relation to this?

Yes, think of the formula: Energy Lost (h) = K * (v²)/(2g), where K is dependent on pipe characteristics. Remember this as: *Energy equals Capability*.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section delves into the dynamics of fluid flow in pipes, highlighting the importance of understanding turbulent and laminar flow regimes, the calculation of major and minor losses, and the application of Bernoulli's equation. Key concepts such as Reynolds numbers, friction factors, and the significance of experiment setups in quantifying energy losses are also discussed.

Detailed

Flow Characteristics in Pipes

This section is dedicated to the fundamental characteristics of fluid flow in pipes, particularly focusing on the type of flow, energy losses, and key equations governing pipe design. It emphasizes:

1. Types of Flow

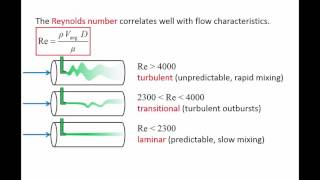

- Laminar vs. Turbulent Flow: The section begins by defining the types of flow based on Reynolds number. Laminar flow occurs at Reynolds numbers less than 2300, while turbulent flow dominates at Reynolds numbers over 4000. The transition zone (2300-4000) is also noted.

2. Energy Losses in Pipes

- Major Losses: These stem from friction, requiring experimental setups to measure pressure differences to compute energy losses based on Bernoulli’s equation.

- Minor Losses: Losses from pipe fittings like bends and valves. Understanding both losses is crucial for predicting energy needs and designing efficient pipe systems.

3. Importance of Experiments

- The lecture refers to experimental setups to quantify energy losses. It highlights the role of major losses and minor losses, extending to energy losses in multiple configurations.

4. Implications on System Design

- A thorough understanding of hydraulic gradients and energy losses is vital in engineering, especially with systems like water supply networks, where pressure management is critical.

In summary, this section integrates theoretical concepts of fluid mechanics with practical experimental methodologies to assess energy losses in pipe flow, providing a foundational understanding necessary for effective designs in civil engineering.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Turbulent Flow

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Most of the times we have the turbulent flow. The turbulence is quantified with respect to Reynolds numbers, which is a ratio between inertia forces and viscous forces. The flow is laminar if Reynolds number is less than 2300 and turbulent if it is greater than 4000, with a transition regime in between.

Detailed Explanation

Turbulent flow is a complex, chaotic flow pattern that occurs in fluids when their velocity exceeds a certain threshold. This threshold is determined by the Reynolds number, which compares the relative strength of inertial forces (those that cause movement) to viscous forces (those that resist movement). A Reynolds number less than 2300 indicates laminar flow, where fluid moves in parallel layers, while a value above 4000 suggests turbulent flow, characterized by swirling eddies and vortices. Between these ranges lies a transition area where flow can fluctuate between laminar and turbulent.

Examples & Analogies

Think of skiing down a hill: when you're gliding smoothly down (laminar flow), it's easy and controlled. But as you reach a steep incline and pick up speed, you start to wobble and swirl, losing control (turbulent flow). At some points during the ride, you may be able to control your movement (the transition region) but will eventually be thrown into chaos as the slope steepens.

Relevance of Velocity and Diameter in Pipe Flow

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In designing water supply systems, factors such as the diameter of pipes and flow velocity are crucial. These parameters affect the overall energy requirements and the efficiency of the flow system.

Detailed Explanation

When engineers design water supply systems, the specifications of the pipes used—including their diameter—play a critical role in dictating how efficiently water can flow. Larger diameters typically allow for greater flow rates, reducing friction and energy losses. Conversely, smaller diameters can increase pressure losses, requiring more energy to pump the same volume of water. The relationship between pipe diameter and flow velocity is essential; increased speed can lead to turbulence, enhancing pressure losses and energy consumption.

Examples & Analogies

Imagine trying to drink a thick milkshake through a narrow straw versus a wide one. The wider straw allows you to sip more milkshake easily (less resistance), while the narrower one requires more effort to get the same amount (more resistance). This mirrors how water flows through pipes of varying diameters.

Experiments to Quantify Losses

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

To measure how much energy loss occurs in pipe systems, we set up experiments to compare pressure differences and velocities between various points, taking into account both major losses (due to friction) and minor losses (due to fittings and bends).

Detailed Explanation

By conducting experiments involving different configurations of pipes, engineers can measure the pressure drop caused by friction (major losses) and the additional losses due to fittings, bends, and other elements (minor losses). Using manometers to gauge pressure differences and calculating flow velocities allows for the quantification of energy losses as per Bernoulli’s equation.

Examples & Analogies

Consider a team conducting a race to determine which route from point A to point B is fastest. They would measure the time taken over different paths (some with 'friction' via obstacles like bumps or turns) to find out which configuration enables the quickest travel, just as we analyze pressure and velocity in pipes to find efficient water flow.

Impact of Pipe Geometry on Flow

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The geometry of pipe bends and fittings significantly influences energy loss due to vortex formation. Sharp bends create turbulent vortices that increase losses, while gradual turns can reduce these effects.

Detailed Explanation

When fluid flows through a pipe, the shape of the pipe and any bends present can cause the flow to separate, leading to swirling patterns known as vortices. These vortices consume energy, resulting in increased pressure drops or energy losses. Engineers seek to design pipe systems that minimize sharp bends and instead favor gradual transitions to maintain smoother flow and lower resistance.

Examples & Analogies

Think about sliding around a corner on a skateboard. If the turn is sharp, you may lose speed and control, causing you to wobble (akin to energy loss due to vortex formations). However, if the turn is smooth and gradual, you can maintain your speed and direction more effectively, resembling a well-designed pipe system.

Key Concepts

-

Flow Types: Laminar flow is smooth, turbulent flow is chaotic. Understand their distinction through Reynolds numbers.

-

Energy Losses: Major losses come from friction in pipes, while minor losses occur at fittings and bends, impacting system efficiency.

-

Bernoulli's Equation: A useful tool for calculating energy losses in fluid flows.

Examples & Applications

In a piping system designed for water, if the Reynolds number exceeds 4000, the flow is considered turbulent, necessitating design adjustments for energy losses.

Using Bernoulli's equation, if the pressure drop across a pipe fitting is measured, engineers can calculate how much energy is lost due to that fitting.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Flow is smooth when it's low, turbulent when it starts to show.

Stories

Once upon a time, in a busy plumbing town, the water was calm and flowed gently through pipes—that's laminar flow! But when the wind picked up, swirling water created whirlpools—this chaos, known as turbulent flow, caused lots of issues for the town's engineers.

Memory Tools

To remember energy losses: F for Friction (major losses), and Mi for minor (fittings) = FM (Friction & Minor).

Acronyms

REMEMBER

PRED (Pressure-Reducing Elbow Design for Resistance) for fittings impacting pressure.

Flash Cards

Glossary

- Laminar Flow

A type of flow in which fluid moves smoothly and in parallel layers.

- Turbulent Flow

Flow characterized by chaotic property changes and mixing of fluid elements.

- Reynolds Number

A dimensionless number used to predict flow patterns in different fluid flow situations.

- Major Losses

Energy losses in a fluid flow due to friction along pipes and surfaces.

- Minor Losses

Energy losses at pipe fittings like valves, bends, and other components.

- Bernoulli's Equation

A principle that describes the relationship between pressure, velocity, and elevation in fluid dynamics.

Reference links

Supplementary resources to enhance your learning experience.