Experimental Setup

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Major and Minor Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will discuss energy losses in pipe systems. Can anyone tell me what major losses are?

Isn't it the losses due to friction in the pipes?

Exactly! Major losses occur primarily due to friction. Now, who can explain what minor losses might entail?

Minor losses happen because of fittings like valves and bends, right?

Correct! To remember this, think of the acronym M&M - Major losses are caused by 'Motion' through the pipe while Minor losses are due to 'Mixing' at fittings.

So, how do we measure these losses?

Great question! We measure losses using manometers to find pressure differences and apply Bernoulli's equation. Let's move to our next session to dive deeper.

Understanding Major Loss Measurements

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

For major losses, we use two pipes connected with manometers. Can anyone explain why we measure pressure difference?

It's to calculate the energy loss due to friction.

Exactly! The pressure difference helps us compute velocity and then deduce the energy loss. Remember this: Pressure loss relates directly to velocity changes.

What factors affect this relationship?

Good question! The characteristics of the pipe, like diameter and roughness, as well as fluid viscosity, all play a part.

And Reynolds number affects whether flow is laminar or turbulent?

Exactly right! Remember, Reynolds number is key. Let's proceed to minor losses next.

Exploring Minor Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's focus on minor losses. How do these differ from major losses?

They occur at fittings, right?

Precisely! Things like bends, valves, and contractions can create vortices, increasing energy loss. How can we quantify these?

Using empirical coefficients for each fitting type?

Exactly! We determine a K value experimentally and use it in calculations. A good mnemonic to remember all these fittings is 'Bend and Extend' for the types of fittings.

What about the flow conditions? Do they affect losses?

Yes, indeed! Changes in flow rate and direction can significantly impact minor losses. This is an essential consideration when designing pipe systems.

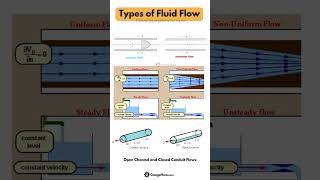

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section elaborates on the principles of fluid mechanics as applied to pipe flow, particularly the mechanisms of energy losses and the experimental approaches to measure these losses in various configurations. Concepts include major losses due to friction and minor losses due to fittings and transitions.

Detailed

In fluid mechanics, especially within pipe systems, understanding energy losses is critical for efficient design and operation. This section highlights the experimental setups utilized to quantify both major losses, caused primarily by friction, and minor losses due to fittings like bends and valves. The focus is on how these losses are measured through pressure differences and flow rates, adhering to the principles of Bernoulli's equation and momentum conservation. Students learn to interpret these losses through experiments simulating real-life water supply systems, preparing them for practical applications in engineering.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Experimental Setup

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Again, I will revisit the virtual fluid balls. Then we will talk about the minor losses in the pipe systems. And again, I have to revisit it what is called energy gradient lines or the hydraulic gradient line which is more important when you are solving this pipe network problems.

Detailed Explanation

In this introductory part of the experimental setup, the focus is on understanding how virtual fluid balls provide insights into flow dynamics. Virtual fluid balls are conceptual tools used to visualize and analyze fluid flow behavior. They help in understanding complex flow phenomena, particularly in the context of pipe systems and how energy losses happen within these systems. Additionally, the concepts of minor losses in pipes and hydraulic gradient lines are crucial as they directly impact the efficiency of fluid transport through pipelines.

Examples & Analogies

Think of virtual fluid balls like the trails left by a collection of moving cars on a highway; just as observing these trails can help you understand traffic flow and congestion, using virtual fluid balls can help visualize and understand how fluids behave inside pipes.

Measuring Energy and Pressure Losses

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So if you look it, we call major losses. Major losses, that is the losses due to the frictions. So that way if you look it there are the two pipes are there. And in these two different pipes there are the manometers are attached to determine what is the pressure difference at the two points.

Detailed Explanation

This chunk discusses major losses in fluid systems, primarily caused by friction between the fluid and the pipe's internal surface. Major losses are quantified using manometers, which measure pressure differences between two points along a pipe. By measuring these differences, we can apply Bernoulli’s equation (with modifications) to calculate the velocity of the fluid and subsequently determine the energy loss due to friction. This setup is essential for understanding how friction influences flow through pipes.

Examples & Analogies

Imagine measuring the difference in height between two water levels in a connected tube, much like how a water level indicator works. The greater the height difference, the more energy (or pressure) is lost as the water flows, similar to how friction slows down a moving vehicle on a rough road.

Understanding Minor Losses

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

But there are minor losses like this is the band is there. There are loss will be there. The band is here, there will be loss. Here also we have the band and there are the valves are there. So all these are called minor losses, as well as there will be the exit loss or contractions loss.

Detailed Explanation

Minor losses refer to energy losses that occur due to changes in flow conditions, such as bends, valves, and contractions in the pipe. These losses are often less significant than major losses but can still have a considerable impact on system performance. They are important to quantify in pipe system designs because ignoring them can lead to underestimating the energy needed to maintain desired flow rates.

Examples & Analogies

Think of minor losses like the detours or speed bumps on a road. Each detour adds a little extra time or energy to your journey, just as bends and valves do in a fluid system. Even if they're small individually, they can collectively add up and significantly affect overall performance.

Calculating Energy Losses

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

These are the experiment setups, the students conduct the experiment with a different research and find out, measure the pressure difference. And with a simple calculations they quantify it how much of energy losses or the head losses happens for minor component as well as the major components like the pipe due to the frictions and the fitting, the elbow, the bends, the exit, the valves all we consider it to find out how much of energy losses are happening it.

Detailed Explanation

In this part, the focus is on the methodology for measuring and quantifying energy losses in pipe systems through experiments. Students conduct practical experiments that involve measuring pressure differences using instruments like manometers, which helps them calculate head losses due to both major and minor losses. By understanding these losses quantitatively, students learn how different fittings and configurations affect the overall energy efficiency of the pipe system.

Examples & Analogies

Consider a basketball game; each missed shot (energy loss) might not seem significant alone, but collectively, they could determine the outcome of the game. Similarly, in a fluid system, both major and minor losses, when measured and considered, can greatly affect overall efficiency and performance.

Virtual Fluid Balls and Vortex Formation

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Here again I have to repeat it to tell it the virtual fluid balls to understand how the vortex formations happens within a pipe flow systems.

Detailed Explanation

This chunk emphasizes the role of virtual fluid balls in illustrating vortex formation within pipes. Vortex formations occur when the fluid changes direction or speed, leading to swirling motions that contribute to energy losses in the system. Understanding these phenomena is critical for designing efficient pipe systems because it helps engineers visualize how fluids behave under different flow conditions.

Examples & Analogies

Think of how a whirlpool spins water in a basin; the swirling motion represents a vortex. Just as the whirlpool causes water to lose energy as it moves, so do vortices in a pipe system. Recognizing and managing these vortices can lead to more efficient designs, similar to how whirlpool effects can be altered by changing the shape of the basin.

Experimental Feedback and Application

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So if you have a contractions, then what it happens it. There will be vortex zones here. There will be vortex zones here. So you can understand it that more energy losses will happen when you will have a contractions okay.

Detailed Explanation

This chunk discusses the impact of contractions in pipe systems, emphasizing that contractions create vortex zones which lead to energy losses. This reinforces the idea that not all configurations are equal; some can significantly increase the energy required to maintain fluid flow. Engineers must understand how to minimize these losses when designing pipe systems to ensure efficiency.

Examples & Analogies

Imagine trying to squeeze through a narrow hallway; the narrower the hallway, the more difficult it becomes to move quickly. Similarly, when fluid moves through a contracting section of a pipe, it encounters resistance and forms vortices, which slow the flow and consume more energy.

Key Concepts

-

Major Losses: Losses due to friction are quantified through pressure differences.

-

Minor Losses: Losses caused by fittings and bends, calculated using empirical coefficients.

-

Bernoulli's Equation: A crucial equation for relating energy losses to flow conditions.

-

Reynolds Number: A crucial parameter for identifying flow type (laminar or turbulent).

-

K Value: An important factor for quantifying minor losses in a numerical manner.

Examples & Applications

An engineer measures the pressure drop across a section of pipe to calculate frictional losses associated with a given fluid.

By observing how different fittings (like bends and valves) alter flow, an engineer can derive K values for use in future designs.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Major losses occur with friction’s strong hand, minor losses caused fit with the flow’s demand.

Stories

Consider a water supply system where friction slows down water flow, while sharp turns create swirling currents that waste energy.

Memory Tools

M&M for Major and Minor losses, Friction and Mixing.

Acronyms

F.M. for Friction major losses and Fittings minor losses.

Flash Cards

Glossary

- Major Losses

Energy losses primarily due to friction in the pipes.

- Minor Losses

Energy losses due to fittings, bends, and transitions in the pipe system.

- Bernoulli's Equation

A principle describing the relationship between pressure, velocity, and height in fluid flow.

- Reynolds Number

A dimensionless quantity used to predict flow patterns in different fluid flow situations.

- K Value

An empirical coefficient used to represent energy losses due to fittings.

Reference links

Supplementary resources to enhance your learning experience.