Minor Losses and Energy Considerations

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Minor Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

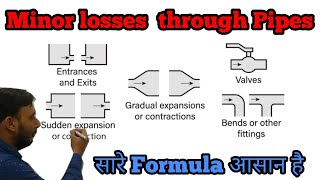

Today, we will explore minor losses in pipe systems and why they matter. Minor losses are energy losses that occur due to fittings and changes in the flow direction. Can anyone tell me how these might differ from major losses?

Are major losses only due to friction in the pipes?

Exactly! Major losses typically arise from friction in the pipe length, while minor losses are due to specific components like bends or valves. Remember the mnemonic 'Fittings Hide Energy' to recall that fittings such as elbows and valves can introduce energy losses.

So, what kind of fittings are responsible for these minor losses?

Great question! Common fittings include bends, valves, expansions, and contractions in the pipes.

Can we quantify these losses?

Yes, we can! We use specific equations to calculate the loss coefficients for each type of fitting, leading us to quantify the energy loss.

In summary, minor losses are key components affecting energy efficiency in fluid systems, with specific fittings contributing to these losses. Keep that in mind as we move forward!

Understanding Reynolds Numbers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss the significance of Reynolds numbers in distinguishing flow conditions. What is the threshold for laminar versus turbulent flow?

Is it 2300? Laminar is below that, and turbulent is above 4000?

Correct! Remember this range: 'Laminar is 0 to 2300, Turbulent is above 4000.' This helps us understand how flow behavior changes.

What about the transitional flow?

Good point! The transitional flow exists between those two thresholds, where flow can fluctuate significantly. Turbulent flow generally results in higher energy losses.

Why do we care about these types of flow?

Understanding the flow type helps us design systems more efficiently and predicts potential energy losses. Always associate 'Reynolds' with flow types!

In summary, keeping Reynolds numbers in mind helps us engineer better systems compromised less by energy losses.

Experimental Methods for Measuring Minor Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let us discuss how to quantify these minor losses experimentally. What methods do we commonly use?

I think using manometers is one way, right?

Exactly! Manometers help us measure pressure differences at various points. These pressure differences provide valuable input for calculating head loss.

Can you explain how we relate pressure difference to energy loss?

Sure! By using the modified Bernoulli’s equation, we can relate pressure difference to energy loss and subsequently calculate minor loss coefficients.

And what factors should we measure during these experiments?

Measure flow velocity, pressure, and any specific configurations of fittings to determine the impact of each on energy loss.

In summary, understanding experimental methods helps us accurately quantify minor losses, which is crucial for effective fluid system designs.

Designing Efficient Pipe Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss how to design pipe systems efficiently. Why is it important to design with minor losses in mind?

To ensure that systems operate effectively without wasting energy?

Exactly! Designing to minimize minor losses helps us maintain flow rates and save energy.

What practical steps can we take when designing?

Consider using smooth fittings, minimizing bends, or using gradual transitions. Each of these designs helps in reducing energy losses significantly.

I see, so it’s a trade-off in design to optimize flow.

Exactly! Always weigh the trade-offs. In summary, efficient design is fundamental to achieving optimal fluid system performance.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section emphasizes the importance of understanding minor losses in fluid systems, especially in terms of energy calculations in pipe fittings. It introduces concepts related to flow transitions, turbulence, Reynolds numbers, and their impact on energy losses.

Detailed

In this section, we delve into the concept of minor losses within pipe systems, which significantly affect overall energy dynamics in fluid mechanics. Key topics include the classification of losses into major and minor types, with minor losses arising from fittings, bends, valves, and contractions in pipe flow. Understanding energy gradient lines, hydraulic gradient lines, and the relationship between Reynolds numbers and flow types (laminar, transitional, and turbulent) is critical. We also explore experimentation methodologies to measure and quantify these losses, using equations derived from Bernoulli’s principle as well as equipment like manometers to assess pressure differences across pipe sections. The significance of designing efficient pipe systems with minimal energy loss, particularly under varying flow conditions, is emphasized throughout this discussion.

Youtube Videos

![[MAE 242] Pipe flow with major and minor head losses](https://img.youtube.com/vi/WH1fn6dMYiw/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Minor Losses

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now let us go to the minor losses in the pipe systems. As I told it when you have the pipes, it can have a regions you have a smaller pipe to bigger pipe or bigger pipe to the smaller pipe. When you have a these conditions that means the flow is coming it here and going out, the smaller diameters and the larger diameter. If you have these conditions, what we do it that when you compute the energy losses, for this total regions, we compute the analysis this.

Detailed Explanation

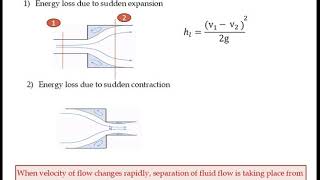

Minor losses in a pipe system refer to energy losses that occur due to changes in flow direction, pipe diameter, or other fittings. When fluid flows through a pipe that transitions from a smaller diameter to a larger one, or vice versa, the flow characteristics change. The energy loss occurs primarily because of turbulence generated in these regions. To evaluate these losses, we analyze how much energy is lost in transitioning from one area to another based on the velocities and diameters of the connected pipe segments.

Examples & Analogies

Imagine riding a bike on a smooth road (large diameter pipe) and suddenly transitioning to a narrow path (small diameter pipe). You feel a jolt as your speed decreases due to the narrow space, similar to how fluid experiences minor losses in pipes. The narrow path causes increased resistance, leading to energy loss, just like turbulent flow in a pipe.

Energy Loss Quantification

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

You can understand it energy losses will have a functions of e square by 2 which is kinetic energy per unit mass into a vectors, which will be responsible for how the flow patterns, how the streamline patterns, how the vortex patterns are (()) (21:31). If you know that, you can quantify it or you conduct the experiments. It is very easy to conduct the experiment of different pipe diameters, different configurations you can compute it. You just measure the pressure at these two point and you know the velocities like the manometers you can put it then you can measure the pressure difference and you can easily quantify that how much of K value from experimentally.

Detailed Explanation

Energy losses can be quantified by analyzing the kinetic energy of the fluid flow, with losses proportional to the square of the velocity difference across sections of pipe. By conducting experiments and measuring the pressure differences between two points in a pipe, students can use the results to calculate the minor loss coefficient (K). It involves measuring the difference in pressure, evaluating the flow velocity, and computing the losses based on these readings.

Examples & Analogies

Think of it like measuring how much energy you use going up and down a roller coaster. If you track your speed at the top (high energy) and at the bottom (lower energy), you can figure out how much energy was lost on turns (similar to pressure measurements in a pipe). By calculating these differences, you can understand where the most energy is being consumed and lost.

Effect of Pipe Fittings

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now let us look it how would it happens it. That again I am considering virtual fluid balls okay. If I consider the virtual fluid balls, the balls which is going very close to the wall, which will go straight and inject here as a tangential and go like this, okay. What will happen to this? Here also we have the particular liquid, but that liquid will have a vortex formation. They will start rotating it, start rotating it. So immediately your flow will pass this, these regions will have a vortex formations. Because of these vortex formations, you will have a energy losses.

Detailed Explanation

When considering the flow of liquids in pipes, visualizing 'virtual fluid balls' (or packets of fluid) helps us understand how they interact with the pipe surfaces. When these fluid packets come close to the pipe wall, their behavior changes—they start rotating and forming vortices. This behavior leads to energy losses as fluid continues to flow through sections where these vortices are created, typically at bends and fittings in the pipe system.

Examples & Analogies

Picture a group of marbles rolling in an elliptical track. As they near the edges of the track, they begin to spin and lose some of their speed due to friction with the wall. Similarly, fluid packets closest to the pipe wall experience resistance and lose kinetic energy as they form swirling patterns (vortices), causing minor losses in pressure.

Vortices and Energy Losses

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

You can understand it that more energy losses will happen when you will have contractions okay, when you will have the contractions. But in case of expansions the vortex zones are the less. So energy losses in this case which will be much higher as compared to the expansion zones because of the vortex formations with the energy dissipations.

Detailed Explanation

Energy losses from vortices are more significant during contractions in a pipe. When the diameter of the pipe decreases, the flow accelerates, causing higher turbulence and vortex formation, which leads to a greater loss of energy. In contrast, during expansions, the flow slows down, and while vortices still form, the energy losses are relatively less because the turbulent effects are reduced.

Examples & Analogies

Imagine trying to squeeze through a tight door (contraction)—you might stumble and lose balance (energy loss) as you rush through. Now consider walking through a wider entryway (expansion)—it's easier and smoother (less energy loss), illustrating how flow behaves in pipes under different diameter conditions.

Impact of Pipe Design

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

But if you can make it a the shape of like this okay gradually variations or gradually expanding it then you can avoid the energy losses what is going to happen because of this vortex in a similar way like this.

Detailed Explanation

To minimize energy losses due to vortices, it is important for engineers to design pipes with gradual transitions between different diameters instead of sharp changes. Gradual expansions allow fluid to decelerate smoothly rather than abruptly, reducing the intensity of vortex formations and subsequent energy losses.

Examples & Analogies

Think of a water slide. If the slide has a sharp drop, riders will experience sudden jolts and splashes (energy loss). However, if the slide gently slopes down, riders glide more smoothly and enjoy the ride (less energy loss). Just like a well-designed water slide, pipes need gradual transitions to optimize fluid flow and reduce losses.

Key Concepts

-

Minor and Major Losses: Differentiating between losses due to fittings and friction.

-

Reynolds Number: Understanding flow types and their thresholds.

-

Bernoulli's Equation: A fundamental equation for energy conservation in fluid mechanics.

-

Experimental Measurements: Methods to quantify energy losses in pipe systems.

Examples & Applications

In a water supply system, using several bends can lead to significant minor losses, which must be calculated to ensure efficient design.

Applying Bernoulli's equation, one can determine the pressure drop across a valve, indicating energy loss.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For minor losses, it’s all about the bends, they help us save energy as we make amends.

Stories

Imagine a water pipeline weaving through a city. Every bend represents a minor loss, reminding us to keep our design efficient.

Memory Tools

R-E-M: Reynolds number, Energy loss, Minor losses - remember these terms together!

Acronyms

F.H.E

Fittings Hide Energy for remembering minor losses.

Flash Cards

Glossary

- Minor Losses

Energy losses occurring due to fittings, bends, valves, and other changes in the flow direction in pipe systems.

- Major Losses

Energy losses attributed to friction in the length of the pipes, significantly impacting the flow.

- Reynolds Number

A dimensionless number used to predict flow patterns in different fluid flow situations.

- Bernoulli's Equation

An equation that describes the conservation of energy in fluid flow, connecting velocity, pressure, and elevation changes.

Reference links

Supplementary resources to enhance your learning experience.