Best Hydraulic Cross Section

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Open Channel Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Good morning, everyone! Today, we are discussing open channel flow and its critical aspects. Can anyone tell me what open channel flow refers to?

Is it the flow of water across a surface like a river or stream?

Exactly! It's when water flows over a channel that is open to the atmosphere. Now, key to understanding this is the concept of specific energy. Can anyone define it?

Is specific energy the total energy per unit weight of the water?

Right! We can express specific energy as a function of flow depth. This is important because different flow conditions can impact the energy losses in our system. Remember this: Specific Energy, "E" relates height and velocity. Let's keep this in mind!

Understanding Flow Types

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about the types of flow we can encounter. We have subcritical, critical, and supercritical flows. How do these differ in terms of Froude number, or 'Fr' for short?

Subcritical flow is when Fr is less than 1, right?

Correct! And what happens at critical flow?

Critical flow is when Fr equals 1, and the flow is at its most efficient state.

Spot on! Finally, supercritical flow corresponds to Fr greater than 1, which has higher velocities. Understanding these types will guide our channel design. To help remember, think of Fr as 'Flow Rate'!

Hydraulic Jumps

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive into hydraulic jumps—what do they signify?

A hydraulic jump occurs when supercritical flow transitions to subcritical flow, causing a sudden increase in flow depth.

Exactly! This transition results in energy losses. Can anyone describe why this is significant in engineering?

It’s crucial for designing channels to properly handle that energy loss without damaging structures.

Right! Hydraulic jumps help mix air into the water, which can be beneficial for certain engineering applications. Remember: Jumps mean turbulence and mixing!

Best Hydraulic Cross Sections

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss the importance of selecting the best hydraulic cross sections for our designs. Why is this important?

It helps minimize construction costs and maximizes flow efficiency.

Exactly! In choosing shapes like rectangular vs trapezoidal, what considerations do we have?

The perimeter and the hydraulic radius play a big role in minimizing resistance.

Precisely! Efficient design means thinking about those metrics. To remember, think of P for 'Perimeter' and R for 'Radius'! Let's also connect that to specific energy.

Application and Calculating Parameters

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

For our final session today, let's apply our knowledge to some calculations. Who can remind me how to calculate the specific energy for given flow conditions?

Isn’t it E = y + (v^2 / 2g)?

That's correct! Now, if we have a channel depth (y) of 1 meter and a velocity (v) of 10 m/s, what would the specific energy be?

Let’s see… E = 1 + (10^2 / (2 * 9.81)) = 1 + 5.1, so E is approximately 6.1 meters!

Great job! Understanding these calculations is crucial for effective channel design. Remember: specific energy dictates design parameters!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores the principles behind designing the best hydraulic cross sections for open channels. It covers concepts such as specific energy, different flow conditions (subcritical, critical, and supercritical), and how they influence design choices in hydraulic engineering. Additional focus is placed on minimizing construction costs while maximizing flow efficiency.

Detailed

Detailed Summary

In this section on Best Hydraulic Cross Section, we dive into the essentials of open channel flow, particularly focusing on how water flows through various channel shapes and the efficiency of these shapes. The important concepts of specific energy, flow depth, and the Froude number are introduced. The section emphasizes different states of flow—subcritical (Fr < 1), critical (Fr = 1), and supercritical (Fr > 1)—and the transitions between these states that often lead to phenomena such as hydraulic jumps, which suggest design considerations.

Key Aspects Discussed:

- The concept of specific energy is defined and related to channel flow height.

- Flow states influence energy conservation and losses, particularly during hydraulic jumps.

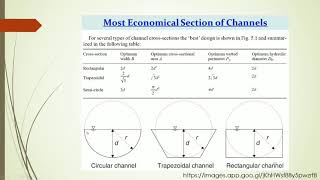

- Advantages of using rectangular, trapezoidal, and circular sections are elaborated upon, with emphasis on optimal design to minimize costs while maximizing flow efficiency.

- Practical examples demonstrate how to derive equations for optimal cross sections and how to calculate the best shape using principles of hydraulics and economics.

- Common formulas and graphical representations underscore the relation between flow depth and cross-sectional dimensions.

Overall, understanding the best hydraulic cross section is crucial for civil engineers to design effective canal systems that could handle various flow demands while being economically feasible.

Youtube Videos

![Open Channel Flow - 6 [Flow Area A, Wetted Perimeter P Hydraulic Radius R, and Hydraulic Depth D]](https://img.youtube.com/vi/lyecuNbxlAs/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Best Hydraulic Cross Section

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

It is not best is looking for best anything related to flow, it is related to the economy. That means if you look at that if I want to construct a channel okay which is I said it channel from a point 1 to point 2 okay have a water flow or any liquid flow from 1 and 2 the points are fixed to carry this water or the liquid from 1 to u. So the slope is more or less fixed slope is more or less fixed it is we cannot change it the slope more or less fixed unless we can put the drops and all but we can have the a point 1 to point 2 we have a constant slope okay. So for the q amount of discharge has to go it okay. So this Q as a design parameters what we are looking it design parameter first is safe right we can have with us okay slope is more less fixed because endpoints are fixed for us.

Detailed Explanation

The concept of best hydraulic cross-section is fundamentally connected to economic efficiency in engineering design. When designing a channel to transport water or other fluids from one point to another, certain parameters are fixed, such as the endpoints and the slope of the channel. Given these constraints, the main goal is to optimize the channel's shape to ensure it can carry a specific amount of discharge (Q) efficiently. This optimization helps in minimizing construction costs and maximizing the performance of the channel.

Examples & Analogies

Think of designing a road to connect two towns. The endpoints of the road are fixed, and while you can choose the road's shape, you want to find the shortest and most cost-effective path. Similarly, for hydraulic channels, while the specific route and slope are fixed, engineers must design the channel shape (like rectangular, trapezoidal, or circular) to efficiently manage the flow of water while minimizing construction costs.

Shapes and Their Impact on Flow

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

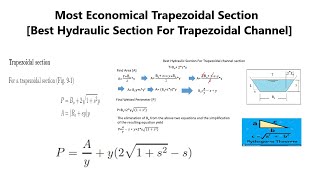

One is a safe you can have with us okay slope is more less fixed because endpoints are fixed for us. So one is a safe you can have rectangles we have a trapezoidal you can have semicircles or circular pipes. So the shapes are can be different type of shapes that is what option with us. What is a relationship with the perimeter and the depth because constant discharge is known for the design discharge.

Detailed Explanation

Various shapes can be utilized for hydraulic channels, including rectangular, trapezoidal, semicircular, or circular pipes. The choice of shape can significantly impact the hydraulic performance of the channel. One important relationship to consider is the connection between the perimeter of the channel shape and the depth of flow. Constant discharge means that regardless of the chosen shape, the amount of water flowing through the channel remains the same. Therefore, engineers analyze different shapes to find the one that minimizes the perimeter while accommodating the necessary flow depth.

Examples & Analogies

Imagine different types of containers for carrying water – a tall and narrow bottle (rectangular), a wide bowl (trapezoidal), and a shallow plate (circular). Each vessel will hold the same amount of water, but their shapes affect how much material is needed to build them. Just like with these containers, when designing a channel for water flow, selecting the shape that minimizes the perimeter while maintaining the required flow depth reduces material costs and enhances efficiency.

Minimizing Construction Costs

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So if you look at that minimum the size of systems is a minimum cost of construction. Smaller the resistance zones average large average velocity and flow rate okay. The resistance we have to reduce it that means you need to have a concrete channels okay. If you reduce the resistance, your velocity will increase it. The flow carrying capacity will increase it.

Detailed Explanation

The overall aim when designing hydraulic cross-sections is to minimize construction costs while ensuring the efficiency of the flow. Smaller resistance zones lead to higher average velocities and flow rates, which means that the channel can carry more water effectively. To achieve this reduction in resistance, engineers may opt for smoother materials like concrete for the channel, as rough surfaces can impede flow. By improving the channel's design and materials, engineers enhance its flow carrying capacity, leading to better performance.

Examples & Analogies

Consider a water slide at a water park. The smoother the slide's surface, the faster the water can flow down. If the slide is bumpy or covered in debris, the water will slow down. Similarly, designing channels to have smooth surfaces (like using concrete) will ensure that water flows quickly and efficiently, thus offering a higher capacity for transporting water while being cost-effective.

Maximizing Hydraulic Radius

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

That is the reason we are cleaning the drainage system so oftenly. Otherwise it raises. Maximum hydraulic radius which is maximum average flow velocity okay. So basically best hydraulic sections which is that maximum hydraulic radius or minimum wetted parameters for these specific cross sections okay.

Detailed Explanation

The hydraulic radius, defined as the area of flow divided by the perimeter, is crucial in designing efficient hydraulic sections. Maximizing the hydraulic radius leads to increased average flow velocity. Conversely, a minimum of wetted perimeter decreases resistance and allows the system to function more effectively. Engineers strive for designs that optimize these parameters, leading to the best hydraulic conditions.

Examples & Analogies

Imagine a garden hose. If you pinch the hose to reduce its diameter (increasing resistance), the water flows out more slowly. But if you keep the hose as wide as possible (maximizing the hydraulic radius), the water flows out quickly and efficiently. In hydraulic design, the same principle applies – larger hydraulic radii allow for better flow rates.

Final Thoughts on Designing Hydraulic Sections

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So we try to look at the aspect ratios flow depth by the channel depth y by b and we here we are just looking it for a rectangular cross sections what will be the relationship between b and y so that the perimeter should be minimum. okay that is the simple things okay. So we try to look it first a flow area is equal to y into b.

Detailed Explanation

When designing hydraulic sections, especially rectangular cross-sections, it is essential to analyze the aspect ratio, defined as the flow depth (y) in relation to the width of the channel (b). This relationship helps in identifying how to minimize the wetted perimeter for a given area, further reducing resistance and enhancing flow.

Examples & Analogies

Think of balancing a glass of water. If the glass is too wide, water will overflow easily without providing much height. Likewise, a very tall glass may hold a lot but spills easily as well. In hydraulic design, there’s a sweet spot; you want enough width in a channel to allow for good flow without wasting material, analogous to finding the right size of a drinking glass that is both stable and holds enough water.

Key Concepts

-

Specific Energy: The energy per unit weight of fluid in a system, critical for understanding energy interactions.

-

Froude Number (Fr): A significant dimensionless metric indicating flow regimes, establishing whether a flow is subcritical, critical, or supercritical.

-

Hydraulic Jump: An essential consideration in engineering design representing the transition points between different flow states, often leading to potential energy loss.

-

Hydraulic Radius: Essential for determining flow efficiency in channels, calculated by the ratio of cross-sectional area to the wetted perimeter.

Examples & Applications

Example of calculating specific energy for a flow depth of 1 meter and velocity of 10 m/s.

Demonstrating a hydraulic jump transition from supercritical to subcritical flow in a spillway.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For each flow depth we must know, Specific energy helps it flow.

Stories

Imagine a river flowing steadily that suddenly faces a drop; here, it jumps, causing a splash up top!

Memory Tools

Remember: Froude is Fast (Fr > 1) for super, steady, or Slow (<1) when it's subcritical!

Acronyms

SE = Specific Energy, a method to define flow depth and speed!

Flash Cards

Glossary

- Specific Energy

The total energy per unit weight of water in an open channel, expressed as a function of flow depth and velocity.

- Froude Number (Fr)

A dimensionless number indicating flow type, calculated as the ratio of flow velocity to the wave speed.

- Hydraulic Jump

A sudden change in flow conditions when supercritical flow transitions to subcritical flow, characterized by a drop in flow velocity and an increase in flow depth.

- Hydraulic Radius

The ratio of the cross-sectional area of flow to the wetted perimeter, influencing velocity and energy in the channel.

Reference links

Supplementary resources to enhance your learning experience.