Flow in Rectangular Conduits

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Hydraulic Diameter

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we'll discuss the flow in rectangular conduits, starting with the concept of hydraulic diameter. Can anyone tell me what hydraulic diameter is?

Is it the diameter that accounts for the shape of the conduit?

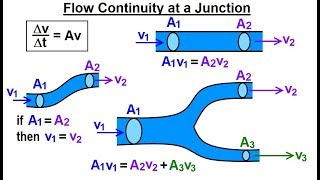

Exactly! The hydraulic diameter is calculated using the formula $$D_h = \frac{4A}{P_w}$$, where A is the area and P_w is the wetted perimeter. Why do you think hydraulic diameter is important?

It helps us analyze noncircular flow as if it were circular!

Right! It simplifies our calculations significantly. Remember: for a full circular pipe, the hydraulic diameter equals the actual diameter.

What happens if the conduit is partially filled?

Great question! In that case, we'd only use the wetted perimeter that is in contact with the fluid. So, what's the main takeaway from this topic?

We can use hydraulic diameter to analyze flow in various shapes?

Absolutely! This foundational concept is crucial for our understanding of fluid flow in all types of conduits.

Flow Regimes and Shear Stress Distribution

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s differentiate between laminar and turbulent flow in rectangular conduits. Student_1, what do you remember about laminar flow?

Isn't it where the fluid flows in layers without mixing?

Exactly! During laminar flow, the wall shear stress reaches a maximum at the midpoints of the sides of the rectangle. Student_2, can you describe turbulent flow?

It’s chaotic and has high mixing, right?

Correct! In turbulent flow, the shear stress distribution is more uniform along the sides. So, how does understanding this help us in real-world applications?

It helps in designing efficient systems and predicting behavior.

Exactly! Knowing the flow regime is critical for proper system design, especially in drainage and piping.

Applications in Civil Engineering

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about practical applications of our knowledge. What are some areas where we use these principles?

In wastewater management and drainage systems!

Yes! In these systems, the shape of the conduits isn't always circular. Student_1, why is it essential to know about flow in rectangular sections?

To ensure the designs accommodate the actual flow behavior?

Exactly! Engineers need to predict flow patterns and shear stress to design effective infrastructure. What would happen if we ignored these properties?

We might face issues like blockages or inefficient transport!

Right! Understanding fluid flow in noncircular conduits is crucial for sustainable design. Let’s recap some key points before we finish.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we explore the characteristics of fluid flow through rectangular conduits, examine how hydraulic diameters help in analyzing noncircular flow patterns, and discuss the impact of flow regimes on shear stress distribution.

Detailed

Flow in Rectangular Conduits

In fluid mechanics, understanding the flow in rectangular conduits is essential for various applications in civil engineering. This section delves into the methods for analyzing noncircular conduits, including the concept of hydraulic diameter, which simplifies the analysis similar to that of circular pipes.

Key Points:

-

Hydraulic Diameter Definition: The hydraulic diameter (

$$ D_h = \frac{4A}{P_w} $$

where A is the cross-sectional area and P_w is the wetted perimeter) allows the treatment of various conduit shapes as if they were circular. - Flow Patterns: The characteristics of flow can vary significantly with the shape of the conduit; for instance, laminar flow in rectangular conduits exhibits different shear stress distributions compared to turbulent flow.

- Shear Stress Distributions: In laminar flow, wall shear stress is maximized at the midpoint along the sides of the rectangle, while in turbulent flow it tends to be more uniform.

- Fluid Dynamics Applications: Knowledge of these principles aids in designing systems such as drainage channels, water supply infrastructure, and sewage treatment plants, where fully circular assumptions may not apply.

Thus, understanding the flow in rectangular conduits and calculating their hydraulic diameters equip engineers with the tools needed to predict system behaviors in real-world scenarios.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Hydraulic Diameter

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now coming to the other case, many of the times also we do not go for only the circular conduits or the circular pipes from one point to other points okay. But when you go for a noncircular case you need to define as a equivalent flow okay. So that means we introduce a hydraulic diameters okay, it is called as hydraulic diameters, 4\[D_h = \frac{4 \times Area}{Wetted \, Perimeter}\]

Detailed Explanation

When we talk about flow in noncircular conduits such as rectangular or triangular shapes, we have to introduce the concept of 'hydraulic diameter.' The hydraulic diameter is a way to relate the noncircular shape to a circular one by considering the area of flow and the wetted perimeter (the part of the perimeter that is in contact with the fluid). This means that for a rectangular section, for example, you would calculate the flow area produced by the width and height, then calculate the wetted perimeter by summing up the lengths of the sides that are in contact with the fluid. The hydraulic diameter is used to help calculate flow characteristics like velocity and shear stress.

Examples & Analogies

Imagine a garden hose and a rectangular fish tank. If you want to compare the flow of water from both, you can't just compare their diameters. Instead, you consider the entire area of water flowing through the hose and the tank's base, which is more complex. Just like you would use the hydraulic diameter to understand water flow from a rectangular conduit, you would consider the total area and perimeter of water flow in the fish tank to evaluate its efficiency.

Calculating Flow in Different Shapes

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now come back to the noncircular conduit like you may have a conditions where you have a only flow through this ones okay. That is called circular annulus diameter. 4\[D_{h} =\frac{(A_{1} - A_{2})}{(P_{1} - P_{2})}\] where A is area and P is wet perimeter.

Detailed Explanation

When you are dealing with shapes other than circular pipes, like annulus shapes or rectangles, the calculation of the hydraulic diameter becomes vital. For example, in an annulus (the space between two circles), you calculate the flow areas A1 and A2, and the perimeters P1 and P2. The hydraulic diameter gives you a measure of the effective diameter to use in equations for flow rate and velocity to help ensure accuracy in your calculations.

Examples & Analogies

Think of a double-walled coffee mug where you fill water between the two walls. The space where the water flows resembles an annulus. To understand how fast the water can flow through that gap, you would need to calculate the area available between the walls and its perimeter, similar to calculating the hydraulic diameter for accurate flow predictions.

Effects of Shape on Velocity and Shear Stress

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now let us come it with that when you have a noncircular pipe like if you have a pipe like a triangular shape okay. So in this case what will happen the if you have a laminar flow you will have a wall stress will be maximum near the mid points of the sides.

Detailed Explanation

The shape of the conduit significantly affects flow behavior. In a triangular conduit with laminar flow, you can expect the highest wall shear stress to be near the mid-point of each side. This means the fluid experiences more friction and drag against the wall at these points, which can affect overall flow characteristics and efficiency.

Examples & Analogies

Consider a slide at a playground. When sliding down a slide that has a steep slope, you experience a lot of speed (analogous to flow), but you also feel pressure (analogous to shear stress) more at the edges where the slide touches you. Similarly, fluid flowing in a triangular shape will experience the greatest shear stress at certain points against the wall, impacting how smoothly the fluid flows.

Understanding Turbulent Flow

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now if you look it that if you have the turbulent flow same case you have a turbulent flow the velocity distributions as well as the wall shear stress distributions exchanges it.

Detailed Explanation

In turbulent flow within noncircular conduits, the behavior changes significantly compared to laminar flow. The velocity distribution is more uniform, and wall shear stress is less concentrated at specific points. This means fluids can flow through the conduit much faster and with more efficiency than laminar flow, but it may also produce more energy loss due to increased turbulence and mixing.

Examples & Analogies

Imagine a busy highway during rush hour as opposed to a quiet side street. On the busy highway (analogous to turbulent flow), cars are moving quickly and closely together, resulting in mixed traffic patterns. However, on the side street (analogous to laminar flow), cars are spaced out and moving one after the other more smoothly. The busy highway allows for higher overall speeds, but there's also greater potential for delays (energy loss) due to traffic congestion.

Key Concepts

-

Hydraulic Diameter: A length scale used to derive coefficients for flow calculations in noncircular conduits.

-

Wetted Perimeter: The section of the perimeter that is in contact with the fluid, crucial for calculating hydraulic diameter.

-

Laminar Flow: Characterized by smooth, layered flow; important for understanding shear stress dynamics.

-

Turbulent Flow: More chaotic and unpredictable, affecting energy loss calculations significantly.

Examples & Applications

An irrigation ditch is rectangular; use hydraulic diameter to analyze flow effectiveness.

In a partially filled rectangular channel, only account for the wetted perimeter in hydraulic diameter calculations.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Flow in a pipe, big or small, use diameter to sum it all!

Stories

Imagine an engineer designing pipes. To ensure flow, he measures the area and wetted perimeter with care, knowing the hydraulic diameter is his best tool for predicting how water will behave.

Memory Tools

Remember 'H-A-P' for hydraulic diameter: H is for Hydraulic, A is for Area, and P is for Wetted Perimeter.

Acronyms

MVP for remembering key components

for Maximum shear in laminar flow

for Velocity distribution

and P for Perimeter in hydraulics.

Flash Cards

Glossary

- Hydraulic Diameter

A measure used to characterize noncircular conduits, calculated as $D_h = \frac{4A}{P_w}$, where A is the area and $P_w$ is the wetted perimeter.

- Laminar Flow

A smooth and orderly flow regime where fluid flows in layers.

- Turbulent Flow

A chaotic flow regime characterized by mixing and eddies.

- Wetted Perimeter

The part of the perimeter of the conduit that is in contact with the fluid.

- Shear Stress

The force per unit area acting parallel to the surface in the direction of flow.

Reference links

Supplementary resources to enhance your learning experience.