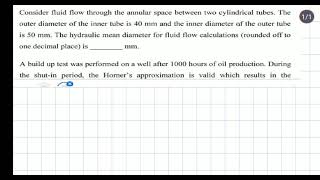

Hydraulic Diameter Calculation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Basics of Hydraulic Diameter

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore the concept of hydraulic diameter. Can anyone tell me why we might need a distinct measure like this when discussing different conduit shapes?

Is it because different shapes can behave differently under flow?

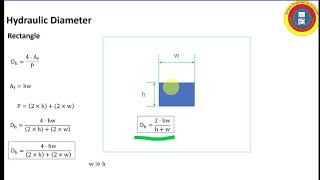

Exactly! The hydraulic diameter allows us to quantify and compare these different shapes. Remember, it's defined as Dh = (4 * Area) / Wetted Perimeter.

So does this mean that the hydraulic diameter can be equal to the actual diameter of a circular pipe?

Yes, that’s correct! But for noncircular geometries, you'll need to compute it differently. Let's say for a rectangular section, if you remember how to calculate area and perimeter, you can derive its hydraulic diameter.

Could you give us a formula for that?

Gladly! For a rectangle, it's Dh = (4 * b * h) / (2 * b + 2 * h). Any questions about this so far?

Just to confirm, would the same principle apply for triangular sections?

Correct, you would calculate the area and wetted perimeter accordingly! Now, let's summarize: hydraulic diameter helps us analyze noncircular conduits by providing a common measure.

Calculating for Different Geometries

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

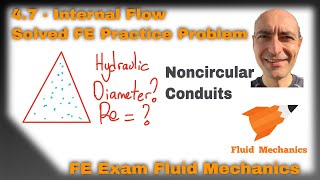

Now, let's apply what we've learned to different geometries. Who can tell me how to calculate for a triangular pipe?

Isn't it similar? We still need the area and the wetted perimeter?

Yes, but how would you find those values for a triangle?

The area would be 1/2 the base times height, right?

Spot on! And the wetted perimeter for an isosceles triangle would involve the two equal sides plus the base. So, what's our formula going to look like?

Dh = (4 * area) / (wetted perimeter)!

Exactly! Remembering these concepts will aid you in various fluid dynamics applications. Let’s summarize today’s idea: understand the geometry, calculate area and perimeter, and you'll compute the hydraulic diameter effectively.

Practical Applications and Implications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about why hydraulic diameter matters in applied settings. Who can think of a situation where hydraulic diameter might be important?

Well, in designing stormwater management systems, flow in noncircular setups is common.

Exactly! Judging flow and potential energy losses requires the use of hydraulic diameter. Can anyone recall how energy losses might differ based on conduit shape?

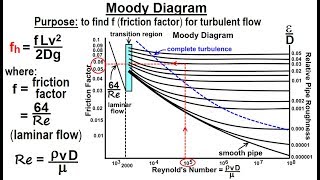

I think the roughness of the surface can affect that, right? Like in the case of pipes with more frictional resistance.

Well said! More turbulence can be observed in irregular pipe shapes, causing greater energy loss. Lastly, remember, hydraulic diameters expand this understanding beyond simple circular shapes.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section on hydraulic diameter calculation addresses how to determine the hydraulic diameter for noncircular conduits, explaining the relationship between flow area and wetted perimeter. It highlights the importance of hydraulic diameters in characterizing flow behavior in various shapes, such as rectangular and triangular conduits.

Detailed

Detailed Summary

The hydraulic diameter is a critical concept applied in fluid mechanics to evaluate the flow in noncircular conduits. It is defined as the ratio of four times the flow area to the wetted perimeter. This is particularly important as it allows engineers and scientists to analyze and draw comparisons between noncircular flows and circular flows. The hydraulic diameter (Dh) for a circular pipe that is fully filled with fluid is equal to its actual diameter. However, for partially filled conduits, or for differing geometries such as rectangles or annuli, the hydraulic diameter must be calculated using the appropriate wetted perimeter.

In this section, the nuances of calculating the hydraulic diameter for different conduit shapes, including rectangular and annular, are explored. The students are introduced to examples of flow in triangular conduits as well, where the wall shear stress and velocity distribution patterns are significantly different from those of circular pipes. The significance of employing hydraulic diameters extends into real-world applications, allowing for accurate predictions of fluid behavior and energy losses, and is essential in fields ranging from civil engineering to environmental studies.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Hydraulic Diameter

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now coming back to the turbulent flow again we can follow the same head loss equations. The head loss is a functions of the velocity head which is...

Detailed Explanation

The hydraulic diameter (H_d) is a key parameter in fluid mechanics when dealing with noncircular conduits. It is essential in determining the behavior of fluid flow in channels that are not perfectly circular. Hydraulic diameter is calculated using the formula: H_d = 4A/P, where A is the cross-sectional area of the flow and P is the wetted perimeter. This equation effectively gives a 'diameter' value that can be used in modeled equations as if the fluid was flowing in a circular pipe.

Examples & Analogies

Imagine a garden hose that is perfectly circular and a flat rectangular gutter. Both are used to carry water, but their shapes and thus how water flows within them can be quite different. The garden hose has a clean cross-section area and wetted perimeter that allow it to flow smoothly. In contrast, for the rectangular gutter, we need to find the hydraulic diameter to predict how efficiently the water will flow, despite its non-circular shape. This is like comparing two different pathways a person might take—a round pathway might be smoother while a zigzag pathway may require careful navigation.

Hydraulic Diameter in Noncircular Conduits

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In this case, what will happen if you have a laminar flow you will have a wall stress will be maximum near the mid points of the sides.

Detailed Explanation

When fluid flows through a noncircular conduit, such as an isosceles triangle, the characteristics of flow can change based on the shape. In laminar flow, the maximum wall shear stress occurs at the midpoints of the triangular sides, creating a different pattern compared to flow in a circular pipe. The wall shear stress is also zero at the corners of the triangle. This behavior showcases how geometry directly influences fluid dynamics—specifically how shear stress varies with position along the sides of the shape.

Examples & Analogies

Think of squeezing a tube of toothpaste. If the tube is round, you will see uniform pressure all around and the paste will flow easily. But if the tube is shaped like a triangle, the pressure applied at different points will create varied shapes of paste coming out. The midpoints of the sides experience the highest pressure, while the corners see none at all. Understanding these principles helps in designing conduits in engineering to manage fluid flow effectively.

Effect of Geometry on Shear Stress Distributions

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In turbulent flow, the velocity distributions as well as the wall shear stress distributions exchanges it.

Detailed Explanation

In turbulent flow, the distribution of velocity and shear stress is quite different from laminar flow. For noncircular shapes, the turbulent flow often leads to more complicated patterns of velocity and shear stress. This includes conditions where the shear stress at the corners is zero while being nearly uniform along the flat sides. Understanding these variations is crucial when considering energy losses in a pipe system and selecting the appropriate hydraulic diameter for calculations.

Examples & Analogies

Picture a busy highway as a representation of turbulent flow. Cars (representing fluid particles) move chaotically rather than in a straight line (as in laminar flow). The speed of cars is not uniform; some areas may be congested (high shear stress) while others are smooth (low shear stress). Just as engineers study traffic patterns to improve flow and reduce jams, fluid mechanics study these patterns to minimize energy loss and optimize fluid transport.

Empirical Relationships and Practical Applications

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Always you can have this type of vortex formations, okay. This type of vortex formations we call the secondary flow generations.

Detailed Explanation

Vortex formations in noncircular conduits generate secondary flow patterns that impact the main flow characteristics. A thorough understanding of these secondary flows is vital as they contribute to pressure losses and energy dissipation in piping systems. Engineering solutions often need to account for these complexities to effectively design systems that handle fluid flows in real-world applications.

Examples & Analogies

Consider how whirlpools form in a sink. As the water swirls around, it creates a secondary flow pattern that affects how quickly water drains. Engineers must consider these dynamics when designing plumbing systems. Similarly, understanding the hydraulic diameter and secondary flows allows civil engineers to optimize water management systems, ensuring efficient drainage and minimizing energy losses in pipes.

Key Concepts

-

Hydraulic Diameter: A measure used for noncircular conduits calculated through the formula involving area and wetted perimeter.

-

Wetted Perimeter: Critical for calculating hydraulic diameters; only the perimeter that the fluid touches.

-

Flow Area: The area through which the fluid moves, important for determining flow characteristics.

Examples & Applications

Example 1: For a rectangular conduit with a width of 2 m and a height of 1 m, the area is 2m * 1m = 2m². The wetted perimeter is 2(2+1) = 6m, leading to a hydraulic diameter of Dh = (4*2) / 6 = 1.33m.

Example 2: For an isosceles triangular conduit with a base of 2m and height of 1m, the area is 1m². If both sides are equal to 1.5m, the wetted perimeter is 2.5 + 2(1.5) = 5.5m, giving Dh = (4*1) / 5.5 = 0.73m.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For conduits that's not round, hydraulic diameter must be found. Area to perimeter, just divide, it helps us measure flow with pride.

Stories

Imagine a water park where different slides twist and turn. A wise engineer measures each one’s flow by finding their hydraulic diameter to keep the fun going smoothly!

Memory Tools

A mnemonic to remember: A-P-P (Area, Perimeter, Hydraulic Diameter) helps in calculating flow in any geometry.

Acronyms

Remember A-P-W, where A stands for area, P for perimeter, and W for wetted, for understanding hydraulic calculations.

Flash Cards

Glossary

- Hydraulic Diameter

The diameter used to characterize noncircular conduits, calculated as four times the flow area divided by the wetted perimeter.

- Wetted Perimeter

The part of the perimeter of a cross-section of a conduit that is in contact with the fluid.

- Area

The space within the geometrical boundaries of the conduit cross-section, important for calculating flow characteristics.

- Flow Behavior

Refers to how fluids move and interact with boundaries in different conduits.

Reference links

Supplementary resources to enhance your learning experience.