Roughness in Open Channel Flow

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Roughness in Open Channel Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll discuss the concept of roughness and how it impacts open channel flow. What do you think surface roughness means in the context of fluid mechanics?

I think it refers to any unevenness on the surface that water flows over.

Exactly! Rough surfaces can cause turbulence in the flow, which increases energy losses. Can anyone tell me why that’s important for engineering applications?

It’s crucial because we need to account for energy losses when designing systems like pipes or channels.

Great point! Remember, we refer to these energy losses as major and minor losses. Major losses occur due to friction while minor losses are due to bends and fittings. Can you think of examples of when this would matter in real life?

In water supply systems where we need to pump water efficiently.

Correct! Understanding roughness helps engineers design systems that minimize losses. To remember this, think of 'Rough surFace, Reduced flow efficiency'!

In summary, roughness is a crucial factor affecting flow characteristics and energy losses in fluid systems.

Nikuradse's Experiments

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss Nikuradse's experiments conducted in the 1930s. What did he do to analyze the effects of roughness on flow?

He used pipes with different surface roughness created by sand grains, right?

That's correct! He aimed to quantify how these rough surfaces influenced wall shear stress and velocity distributions. Why do you think this was valuable?

Because it helped create empirical formulas that are still used today!

Precisely! Nikuradse developed the Moody chart, which is crucial for engineers to estimate friction factors based on roughness and Reynolds numbers. Can anyone recall the relationship between Reynolds number and flow type?

Laminar flows have lower Reynolds numbers, while turbulent flows have higher values.

Exactly! In summary, Nikuradse's work was groundbreaking, giving us tools to analyze fluid flow under rough conditions.

Defining Hydraulic Diameter

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s talk about hydraulic diameters, particularly in non-circular conduits. Why is this measurement important?

It helps us compare the effective flow area of different shapes!

Exactly, the hydraulic diameter is calculated from the cross-sectional area and the wetted perimeter. Can anyone give me the formula?

It's four times the area divided by the wetted perimeter, right?

That's right! Remember the acronym 'HDP' for Hydraulic Diameter = (4 × Area) / Wetted Perimeter. Can you think of a situation where this would apply?

In designing drainage channels or when dealing with irregular shapes in construction!

Absolutely! Hydraulic diameter is essential for effective fluid transport. In summary, it allows us to analyze flow in non-circular geometries effectively.

Velocity Distribution in Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s now focus on velocity distributions in turbulent flows. How does surface roughness influence these distributions?

Rough surfaces can create more turbulence, which affects how the velocity varies across the pipe's cross-section.

Exactly! In turbulent flow, the velocity profile tends to flatten out compared to laminar flow. Why is understanding this profile important?

It helps in predicting shear stress and energy losses!

Correct! The wall shear stress will vary depending on the flow depth and roughness. We can summarize this relationship using the formula: τ = f(V, R). What does each variable represent?

τ is shear stress, V is velocity, and R is hydraulic radius!

Great job! To wrap up, roughness impacts velocity distribution significantly, creating variations in flow behavior.

Applications of Roughness Concepts

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, how do the concepts we discussed apply in real-world applications like sewage treatment or water supply?

Understanding roughness helps engineers design more efficient systems by minimizing energy losses!

Exactly! By analyzing roughness effects, we ensure systems are efficient and reduce costs. Can you remember the key takeaways from our discussion on roughness?

Roughness affects flow characteristics, leading to turbulence and energy losses, which we account for in design!

Yes! Remember, smooth surfaces lead to efficient flows. In summary, understanding roughness allows for better designs in fluid mechanics applications.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

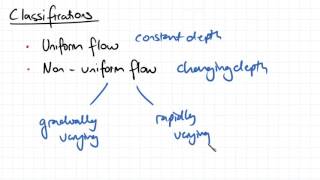

This section delves into the effects of surface roughness on open channel flow, detailing historical experiments that established empirical relationships. It further discusses how hydraulic diameters are defined for non-circular conduits and their influence on flow behavior, including shear stress distributions and velocity profiles.

Detailed

Roughness in Open Channel Flow

This section examines the impact of roughness in open channel flows, marked by a historical perspective on fluid mechanics experiments, particularly those conducted by Professor Nikuradse. These seminal experiments, established in the 1930s, provided fundamental insights into how surface roughness alters flow characteristics, primarily in turbulent pipe flows.

Key Points:

- Definition of Roughness: Roughness refers to irregularities on the surface of a conduit that cause energy losses and influence flow patterns.

- Nikuradse's Experiments: By varying the roughness using sand grains in pipes, Nikuradse identified relationships between flow behavior and parameters such as Reynolds number, wall shear stress, and energy losses in turbulent flow.

- Hydraulic Diameter: In open channels and non-circular conduits, hydraulic diameters play a crucial role, defined by the cross-sectional area and wetted perimeter, which significantly affect flow equations.

- Velocity Distribution: The section highlights varying velocity distributions in laminar vs. turbulent flows, showcasing how roughness leads to eddies and fluctuating shear stresses across the flow cross-section.

- Applications: Understanding these principles is essential for designing effective fluid transport systems, such as sewage treatment facilities and water supply networks.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Roughness Experiments

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Very interesting experiments were conducted almost 70 years back. The classical experiment conducted by Nikuradse involved using pipes with roughness created by sand grains to study flow characteristics.

Detailed Explanation

This chunk introduces the historical context of roughness in open channel flow and highlights a pivotal experiment by Nikuradse. His setup involved pipes with enhanced roughness, which allowed him to observe how these rough surfaces affected fluid flow characteristics, such as velocity distributions and energy losses.

Examples & Analogies

Imagine sliding down a smooth slide versus a bumpy one. On a smooth slide, you glide effortlessly, but on the bumpy slide, you would slow down significantly due to the increased friction from the bumps. This concept directly relates to how rough surfaces in pipes affect the flow of water.

Understanding Roughness Effects

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In pipe flow, roughness can significantly alter flow characteristics, influencing factors like wall shear stress and energy losses.

Detailed Explanation

Rough surfaces in pipes introduce resistance to flow, which can lead to increased wall shear stress—pressure that the fluid exerts against the walls. This resistance changes how fast the fluid can move through the pipe and how much energy is lost as the fluid travels.

Examples & Analogies

Think of a river flowing over a smooth rock versus a river flowing over a rocky bed. The smooth rock allows for easy flow, while the rocks cause turbulence and energy loss, akin to how roughness in pipes affects water flow.

Hydraulic Diameter and Flow Definitions

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Introducing hydraulic diameters for noncircular conduits allows us to define flow more effectively. Hydraulic diameter is a function of area and wetted perimeter.

Detailed Explanation

Hydraulic diameter is crucial when dealing with noncircular pipes because it allows engineers to standardize flow calculations. By defining hydraulic diameter as a function of flow area and wetted perimeter, we can apply similar flow principles used for circular pipes to other shapes, like rectangles or semicircles.

Examples & Analogies

Consider trying to fill a square container with water as efficiently as a round one. Just like understanding how to best utilize different shapes for fluid flow, knowing the hydraulic diameter helps engineers apply the right calculations across varying pipe geometries.

Flow Behavior in Noncircular Pipes

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In noncircular conduits such as triangular pipes, the wall shear stress has unique distributions, impacting how fluid moves.

Detailed Explanation

Noncircular conduits can create complex flow patterns. For example, in a triangular pipe, wall shear stress is maximum at the midpoints of the sides and zero at the corners, which alters how quickly and smoothly the fluid flows. This distribution affects how well the pipe can carry the fluid, as certain areas may experience more friction than others.

Examples & Analogies

Think of a person trying to run on a narrow, triangular path. They can run faster in the flatter middle areas but may stumble at the sharp corners. This analogy illustrates how flow can be more efficient in some areas of a pipe versus others due to shape and shear stress distribution.

Velocity Profiles in Laminar vs. Turbulent Flow

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Velocity distributions vary greatly between laminar and turbulent flows, which can be influenced by roughness and other factors.

Detailed Explanation

Laminar flow occurs in smooth, quiet conditions, resulting in a streamlined velocity profile. Turbulent flow, on the other hand, is chaotic and complex, with velocity profiles that flatten out as flow speed increases. Understanding these differences helps engineers predict how liquids will behave in various pipe conditions and design appropriately.

Examples & Analogies

Imagine pouring syrup (laminar flow) versus water (turbulent flow). The syrup flows steadily in one direction, while the water swirls and moves erratically. This illustrates how varying flow conditions, influenced by factors like pipe roughness, impact fluid velocity in real-world scenarios.

Key Concepts

-

Roughness: Influences flow behavior and energy losses in fluid systems.

-

Hydraulic Diameter: Critical measure for non-circular conduits affecting flow equations.

-

Velocity Distribution: Varies significantly between laminar and turbulent flows due to surface roughness.

-

Wall Shear Stress: Critical for understanding frictional losses and energy efficiency in flows.

Examples & Applications

A pipeline transporting water experiences different flow characteristics when surfaces are smooth compared to when they are roughened with sediment.

In sewage treatment facilities, understanding roughness helps in designing channels that reduce energy consumption while ensuring effective flow management.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For flows that swirl and twirl, rough in touch will make it hurl!

Stories

Imagine a river flowing over smooth pebbles and then over rough rocks. Notice how the flow changes speeds in each case, illustrating how roughness impacts movement.

Memory Tools

Remember to use 'HDP'—Hydraulic Diameter = (4 × Area) / Wetted Perimeter.

Acronyms

R.E.W. for remembering key factors affecting flow

Roughness

Energy losses

Wetted perimeter.

Flash Cards

Glossary

- Roughness

Irregularities on the surface of a conduit impacting flow characteristics and energy losses.

- Hydraulic Diameter

A measure used to compare effective flow areas in non-circular conduits, defined by the formula (4 × Area) / Wetted Perimeter.

- Wall Shear Stress

The frictional force per unit area exerted by fluid in contact with the surface of a conduit.

- Reynolds Number

A dimensionless number used to predict flow patterns in different fluid flow situations.

- Moody Chart

A graphical representation that relates the friction factor for laminar and turbulent flow to Reynolds number and pipe roughness.

Reference links

Supplementary resources to enhance your learning experience.