Fluid Mechanics

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Fluid Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome everyone! Today we will begin our exploration of fluid flow. Can anyone tell me what fluid mechanics entails?

Isn’t it about how liquids and gases move and interact with forces?

Exactly! Fluid mechanics studies the behavior of fluids in rest and motion. It's crucial for applications like piping systems. Now, can someone explain the significance of understanding your system's flow characteristics?

It helps in designing systems that manage flow efficiently and safely.

Right! One key tool is identifying energy losses in a system. Remember the acronym 'GHE', which stands for 'Gradient, Head, Energy'? Let's explore those concepts further.

Nikuradse's Experiments

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

In the 1930s, Nikuradse conducted pivotal experiments with rough pipes. What do you think he was trying to measure?

Was it about how roughness affects flow characteristics?

Correct! He measured wall shear stress and velocity distributions. Do you remember how roughness can alter energy losses?

Yes! Increased roughness typically increases the friction factor.

Exactly. This relationship is illustrated in the Moody chart. Always remember that roughness impacts flow significantly.

Flow in Noncircular Conduits

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's talk about noncircular conduits. What’s the key term we use to define an equivalent diameter for noncircular shapes?

Is it hydraulic diameter?

Correct! The hydraulic diameter is crucial for computing flow behavior in noncircular shapes. Can anyone specify the formula for it?

It’s four times the area divided by the wetted perimeter!

Good job! Understanding these calculations helps engineers design effective piping systems.

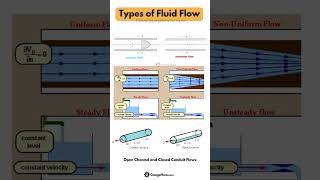

Laminar vs. Turbulent Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive into the differences between laminar and turbulent flow. Who can define laminar flow for us?

Laminar flow is smooth and orderly, with fluid layers sliding past one another.

Great explanation! And how does turbulent flow differ?

Turbulent flow is chaotic, with eddies and vortices present.

Exactly! The transition between these flows is heavily influenced by Reynolds number. Can someone summarize what happens in flow as Reynolds number increases?

As the Reynolds number increases, the flow transitions from laminar to turbulent.

Well done! Understanding this helps forecast flow behavior in various scenarios.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The content addresses principles of fluid mechanics focused on noncircular conduits and multi-path flows. It elaborates on concepts like velocity distribution, wall shear stress, and the significance of experiments in establishing empirical relationships, particularly referencing Nikuradse's pioneering work. The section concludes with practical applications and illustrative examples.

Detailed

Fluid Mechanics: Detailed Overview

In this section, we explore the foundational concepts of fluid mechanics, particularly pertaining to noncircular conduits and multi-path pipe flow. We will highlight the key experiments, specifically those conducted by Nikuradse, that laid the groundwork for understanding turbulent flow characteristics, wall shear stresses, and energy losses. The significance of drawing energy gradient and hydraulic gradient lines for fluid flow analysis is emphasized, along with the calculations of hydraulic diameters for different geometries. Furthermore, we will discuss the behavior of laminar versus turbulent flow in various conduit shapes, including triangular cross-sections, and how these principles remain applicable in modern engineering contexts.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Fluid Mechanics

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Welcome all of you to this fluid mechanics lectures as I am to say is this is the last lectures for this series of the lectures for these 8 weeks and 20 hours lecture series on the fluid mechanics.

Detailed Explanation

This introduction sets the context for a comprehensive course on fluid mechanics that spans eight weeks, totaling 20 hours of lectures. It highlights the importance and relevance of fluid mechanics in engineering applications, implying that students will gain significant knowledge on this fundamental topic.

Examples & Analogies

Think of fluid mechanics as the foundation of learning how water flows in rivers, gets pumped in homes, and moves through complex systems like the human circulatory system. Just as we study different aspects of a river, from the current to the depth, fluid mechanics covers the principles controlling fluid behavior.

Recommended Reading

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

please read the books in written by Cengel Cimbala, Fluid Mechanics Fundamentals and Applications, F. M. White books and I. H. Shames books, Mechanics of the Fluids.

Detailed Explanation

The lecturer suggests essential references for mastering the principles of fluid mechanics. These textbooks provide both fundamental concepts and advanced applications, which are structured to gradually build a student's understanding, from basic theories to more complex fluid flow situations.

Examples & Analogies

Imagine trying to learn how to swim without lessons. Just like a good instructor or a manual guides a swimmer, these textbooks help students navigate through the sometimes turbulent waters of fluid mechanics, ensuring they learn the techniques needed for mastery.

Understanding Noncircular Conduits

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now coming to the other case, many of the times also we do not go for only the circular conduits... hydraulic diameters, okay, it is called as hydraulic diameters.

Detailed Explanation

This section discusses the significance of hydraulic diameters for noncircular conduits, which allows engineers to characterize flow conditions in various geometries. By calculating the hydraulic diameter, students can correctly determine flow behaviors in complex shapes, adapting principles of fluid mechanics to real-world applications.

Examples & Analogies

Imagine trying to pour liquid through various shaped openings like a round bottle, a square box, and a triangular tube. Understanding hydraulic diameter helps engineers predict how smoothly liquid will flow through each shape, much like knowing the best way to pour syrup from a bottle versus a box.

Friction Factors and Reynolds Numbers

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now coming to the turbulent flow again we can follow the same head loss equations... wall shear stress, shear stress at the wall of the pipe.

Detailed Explanation

The section explains the relationship between friction factors and Reynolds numbers in turbulent flow, highlighting empirical formulas that help determine wall shear stress. Understanding this relationship is crucial for engineers in designing efficient pipe systems that minimize energy loss.

Examples & Analogies

Consider driving a car on a highway. The faster you go (akin to high Reynolds numbers), the more friction you feel (similar to friction factors in fluid flow). By understanding these dynamics, engineers learn how to navigate ‘flow’ conditions in pipe systems effectively.

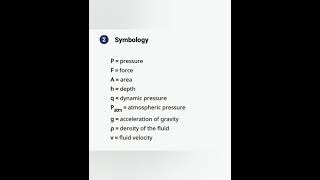

Key Concepts

-

Wall Shear Stress: The tangential stress exerted by fluid on the walls of a conduit, impacting friction in flow.

-

Energy Gradient Line: A line representing the energy levels along a flow path in a piping system, important for tracking energy losses.

-

Hydraulic Gradient Line: A line representing the hydraulic pressures along a flow path that helps visualize pressure changes and losses in a system.

Examples & Applications

An example of a noncircular conduit would be a rectangular duct used in HVAC systems, where the hydraulic diameter is used for calculations.

Nikuradse's experiment with rough pipes demonstrated how roughness ratios affect flow resistance and led to the development of the Moody chart.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In pipes that twist and turn, shear stress is what we learn.

Stories

Imagine a river flowing through a rocky canyon, where the smooth rock allows for easy sailing, but the rough stones cause turbulence and slow down the current. This represents the effects of pipe roughness on fluid behavior.

Memory Tools

Remember 'GHE' for Gradient, Head, Energy to understand flow dynamics.

Acronyms

Use 'RHF' for 'Reynolds, Hydraulic, Friction' to recall essential fluid mechanics terms.

Flash Cards

Glossary

- Hydraulic Diameter

A measure used to characterize the flow in noncircular conduits, calculated as four times the area divided by the wetted perimeter.

- Moody Chart

A graphical representation of the relationship between friction factor and Reynolds number for various types of flow in pipes.

- Reynolds Number

A dimensionless number that helps predict flow patterns in different fluid flow situations, indicating whether the flow is laminar or turbulent.

Reference links

Supplementary resources to enhance your learning experience.