Crack Propagation Mechanisms

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Crack Initiation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start by discussing how cracks initiate in bituminous mixes. Typically, they begin at existing flaws or air voids. Can anyone think of why these areas are particularly susceptible to crack initiation?

Maybe because they're weaker points in the material?

Exactly, Student_1! These flaws create stress concentrations that are more likely to lead to a crack's formation. That's why we emphasize good mix design to minimize such weaknesses.

So, if a crack starts at one of these points, does it just stay there?

Good question, Student_2! The initial crack will typically grow under applied stress unless energy is sufficiently dissipated. This leads into our next topic: crack propagation.

To remember this concept, you can use the acronym 'FLAW' for 'Flaws Lead to A Weakness.'

I like that! It’s easy to remember.

Great! So, does everyone understand how crucial it is to control those flaws in the material?

Yes!

Energy Dissipation and Crack Propagation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's delve into how energy dissipation plays a role in crack propagation. When a crack starts, it grows unless the mix can dissipate the applied energy effectively. Who can tell me how this energy gets dissipated?

Is it by the material's ability to deform or yield?

Exactly! If the material can deform well under stress, it helps absorb and dissipate energy. If not, the crack will continue to propagate, leading to larger failures.

And how do we measure that energy dissipation?

Great question, Student_4! We quantify a material's resistance to crack propagation using **fracture energy (Gf)**. This metric helps engineers assess the mix's durability.

Is higher Gf better?

Yes, a higher Gf values indicate a material that better resists crack growth, which is essential for longevity. Remember, think of Gf as the energy buffer that keeps your pavement intact!

Got it!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

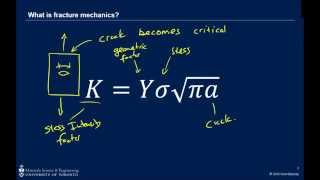

Crack propagation mechanisms in bituminous mixes are critical for understanding how cracks initiate at material flaws and how they propagate due to insufficient energy dissipation. The concept of fracture energy (Gf) is introduced as a measure of a mix's resistance to crack propagation.

Detailed

Detailed Summary

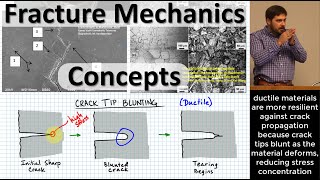

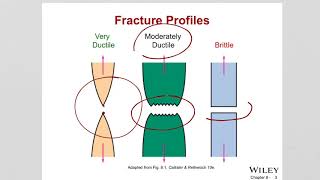

The section on Crack Propagation Mechanisms discusses how cracks develop in bituminous mixes, a crucial aspect in evaluating pavement durability and performance. The initiation of cracks commonly occurs at existing flaws or air voids within the material. Once a crack begins, it propagates under stress due to insufficient energy dissipation in the material. This is where the concept of fracture energy (Gf) emerges, which quantifies a material's ability to resist crack growth. Understanding these mechanisms is essential for engineers designing pavements, as it helps predict the lifespan and maintenance needs of bituminous surfaces.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Crack Initiation

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Initiation at flaws or air voids.

Detailed Explanation

Crack initiation is the first step in the process of crack propagation in bituminous mixes. This typically occurs at microscopic flaws within the material, such as air voids or imperfections. Air voids are small pockets of air trapped in the mix during its formation and can create points of weakness. When the material is subjected to stress (like from traffic loads), these flaws can become the initiation points for cracks.

Examples & Analogies

Think of it like a small chip in a window. The chip represents a flaw, and while the window may seem fine overall, any stress (like pressure from wind) could cause the chip to spread, resulting in a crack. Similarly, in bituminous mixes, initial flaws can lead to larger cracks over time.

Crack Propagation

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Propagation due to insufficient energy dissipation.

Detailed Explanation

Once a crack is initiated, it can propagate or grow through the material. This propagation occurs when the energy applied to the material exceeds its ability to dissipate that energy. In simpler terms, if a load is continually applied without enough time for the material to relax (dissipate energy), the cracks can grow larger. This process explains why pavement can fall apart over time, particularly under repeated stress.

Examples & Analogies

Imagine a rubber band stretched too tightly. If you keep pulling on it without letting it relax, it will eventually snap. In a similar way, if the stress exceeds what the bituminous mix can handle, and the material cannot absorb that energy, cracks will expand and lead to further damages.

Fracture Energy

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Fracture energy (Gf) is used as a metric for resistance.

Detailed Explanation

Fracture energy, denoted as Gf, is a critical parameter in understanding how resistant a bituminous mix is to crack propagation. It quantifies the amount of energy needed to create new cracks in the material. A higher Gf value indicates that the material is more resistant to cracking, meaning it can absorb more energy before failing. Engineers use this information to select materials that will perform better under stress.

Examples & Analogies

Consider a sponge and a rock. The sponge can absorb a lot of water without breaking, while the rock will chip if hit hard enough. In this analogy, the sponge represents a material with high fracture energy (resistant to cracking), while the rock has low fracture energy (prone to cracking under stress). Engineers aim to design pavements that mimic the sponge-like qualities for better durability.

Key Concepts

-

Crack Initiation: Cracks typically start at flaws or air voids in bituminous mixes.

-

Crack Propagation: Once a crack initiates, it grows under stress if energy dissipation is insufficient.

-

Fracture Energy (Gf): A measure of a mix’s ability to resist crack growth, important for durability.

Examples & Applications

Example of a pavement where cracks have initiated at air voids due to poor mix design.

Case of a roadway experiencing accelerated cracking from high tensile stresses and insufficient energy dissipation.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When cracks begin, it's flaws within; keep them low, and strong you'll grow.

Stories

Imagine a road paved with love and care. If the workers left voids or flaws, cracks would appear, running everywhere!

Memory Tools

Remember: 'F-G-C' for 'Flaws Generate Cracks' to keep it clear in your mind.

Acronyms

Use 'SAFE' for 'Sufficient Energy for Fracture Evasion' to remember how to prevent cracks.

Flash Cards

Glossary

- Crack Initiation

The process at which cracks begin to form in bituminous mixes, typically at flaws or air voids.

- Crack Propagation

The growth or extension of a crack once it has initiated, often due to energy not being dissipated effectively.

- Fracture Energy (Gf)

A metric used to measure a material's resistance to crack growth; higher values indicate better resistance.

Reference links

Supplementary resources to enhance your learning experience.