Mechanical Behavior of Bituminous Mixes

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Stress-Strain Behavior of Bituminous Mixes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to explore the stress-strain behavior of bituminous mixes. This behavior can be complex due to several factors. Can anyone tell me what influences how bituminous mixes respond under stress?

Is it the temperature or the speed at which the load is applied?

Exactly! Temperature and loading rate play crucial roles. Bituminous mixes can behave elastically at low temperatures and high loading rates, but they will show viscous behavior at high temperatures or slow loading. We refer to this as viscoelastic behavior — can one of you summarize what viscoelastic behavior means?

It means the material has both elastic and viscous properties depending on conditions.

Correct! That's an important concept. Remember, when we discuss stress relaxation, it refers to a constant strain leading to decreasing stress over time, while creep is the opposite. Now, what can you tell me about the differences between these two behaviors?

Stress relaxation happens when the strain is constant, and the stress decreases, while in creep, the stress stays constant and strain increases over time.

Excellent! Let’s summarize: we learned about the different stress-strain behaviors under varying conditions and the difference between stress relaxation and creep.

Fatigue Behavior of Bituminous Mixes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s dive into fatigue behavior. Who can explain what happens during fatigue failure of bituminous mixes?

The pavement develops cracks from repeated loading even when those loads are below the material's strength.

Right! This failure starts with microcracks that can coalesce into visible cracks. These can lead to issues like alligator cracking. What factors do you think can affect fatigue life?

I think the mix design, temperature changes, and how much load is applied matter.

Good observations! Air voids, binder content, and aggregate type are also critical design parameters. Now, does anyone remember how we test for fatigue in a lab?

The Beam Fatigue Test and the Indirect Tensile Fatigue Test.

Great answers! These tests provide essential data for plotting fatigue life curves. To conclude, fatigue behavior is influenced by a multitude of factors, including mix design and environmental conditions, which significantly influence cracking.

Rutting and Permanent Deformation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s connect to rutting and permanent deformation, which often occurs in wheel paths. Can anyone tell me what causes rutting?

It’s caused by densification and shear flow in the mix under repeated loads.

Exactly! And this phenomenon is more pronounced at high temperatures. Factors such as binder type, aggregate properties, and compaction quality are all contributing elements. Who remembers how we test rutting resistance?

I recall the Wheel Tracking Test and the Dynamic Creep Test.

Right! Conducting these tests allows us to assess how well a mix can handle repeated loading without significant deformation. As a recap: rutting results from specific behaviors under load and is affected by various factors, which can be evaluated using targeted tests.

Stiffness and Modulus of Bituminous Mixes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s now shift our focus to stiffness and modulus in bituminous mixes. What does stiffness indicate?

It indicates how much a mix resists deformation when loads are applied.

Correct! Stiffness can be determined by measuring the dynamic modulus, resilient modulus, or the indirect tensile stiffness modulus. Can someone outline how dynamic modulus is acquired?

It’s obtained from Simple Performance Tests, which measure how mix stiffness responds to cyclic loading.

Exactly! And resilient modulus is essential for structural design since it represents the ratio of recoverable strain to applied stress. To summarize today, we’ve covered the significance of stiffness and different modulus concepts in assessing the mechanical behavior of bituminous mixes.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Bituminous mixes are integral to flexible pavements, and their mechanical behavior is critical for determining road performance. This section delves into the stress-strain relationships, fatigue behavior, mechanisms of rutting, stiffness, fracture resistance, and moisture susceptibility. Each aspect is vital to understanding how pavements can endure varying loads and environmental conditions.

Detailed

Mechanical Behavior of Bituminous Mixes

Bituminous mixes are essential components of flexible pavements, serving both structural and functional roles. Their performance can greatly influence the longevity, safety, and comfort of roadways. Understanding the mechanical behavior of these materials is crucial to predict their responses under various traffic loads and environmental conditions.

Key Areas of Focus

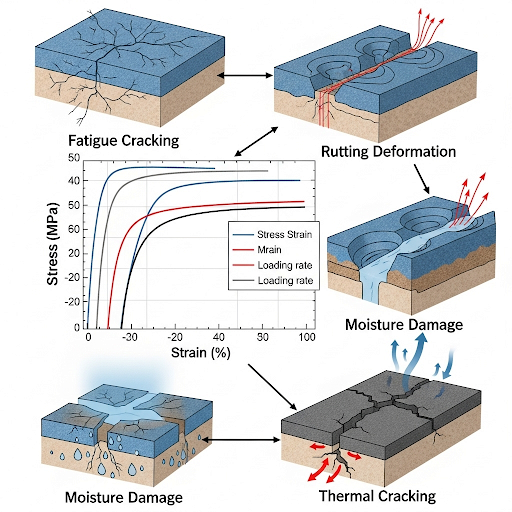

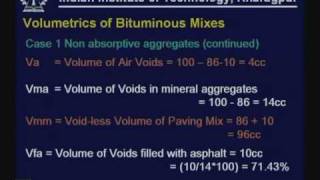

- Stress-Strain Behavior: Bituminous mixes show different stress-strain responses influenced by temperature and loading rates. They can behave elastically (recoverable deformation), viscously (permanent deformation), or viscoelastically (a mixture of both) depending on the conditions.

- Fatigue Behavior: The section explores how repeated loads can produce micro-cracks leading to significant fatigue failure, even with loads below material limits. Factors affecting fatigue life include mix design and environmental conditions.

- Rutting and Permanent Deformation: Permanent deformation under repeated loads leads to rutting in wheel paths, analyzed through test methods to assess resistance.

- Stiffness and Modulus: The stiffness of bituminous mixes can be defined using dynamic, resilient, and indirect tensile stiffness moduli to evaluate their ability to withstand loads.

- Fracture Behavior: This part discusses cracking mechanisms, including thermal cracking and the material's resistance to crack propagation.

- Moisture Susceptibility: The effect of moisture on bond strength between aggregates and bitumen, causing possible structural failures.

Overall, the mechanical behavior of bituminous mixes is critical in pavement design, directly correlating with performance outcomes in real-world applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Bituminous Mixes

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bituminous mixes form the core structural and functional layers of flexible pavements. Their performance directly influences the service life, safety, and riding quality of roads. Understanding the mechanical behavior of bituminous mixes is essential for predicting their response to varying traffic loads and environmental conditions. The study of mechanical behavior involves concepts such as stress-strain relationships, viscoelasticity, fatigue, permanent deformation, stiffness, and fracture resistance. This chapter delves into the physical and mechanical properties of bituminous mixes and the methodologies used to evaluate them in the context of pavement design and performance.

Detailed Explanation

This introduction establishes the importance of bituminous mixes in pavement engineering. It emphasizes that these mixes are crucial components of roads, impacting how long they last and how safe they are for drivers. Understanding how these materials behave under different conditions, such as temperature and load, is necessary for designing effective pavements. By exploring various mechanical properties like stress-strain behavior and fatigue, engineers can make informed decisions to enhance road performance.

Examples & Analogies

Think of bituminous mixes like the foundation of a building. Just as a sturdy foundation supports the entire structure and ensures it withstands environmental stress like wind and rain, bituminous mixes support road surfaces and help them resist the wear and tear from vehicles and weather.

Stress-Strain Behavior of Bituminous Mixes

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bituminous mixes exhibit complex stress-strain behavior due to their heterogeneous and composite nature. The stress-strain response is influenced by temperature, loading rate, and the composition of the mix.

Detailed Explanation

The stress-strain behavior of bituminous mixes refers to how these materials respond to applied forces. Factors like temperature and loading rate can change how these mixes deform when stress is applied. This is essential in understanding how they will perform under real-world conditions on roads, as different mixes will react differently based on their composition and environmental context.

Examples & Analogies

Imagine a rubber band: when you stretch it (apply stress), it deforms. At room temperature, it snaps back to its original shape once you stop pulling. But if you heat it up, it becomes more flexible and might not return to its original shape if stretched too far. This demonstrates how temperature affects materials, similar to how it affects bituminous mixes.

Elastic, Viscous, and Viscoelastic Behavior

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Elastic behavior: At low temperatures and high loading rates, bituminous mixes behave elastically. The deformation is recoverable.

• Viscous behavior: At high temperatures or slow loading, mixes behave like viscous fluids, and deformation is permanent.

• Viscoelastic behavior: Under intermediate conditions, the mix shows time-dependent strain recovery—this is the most realistic representation of bituminous material behavior.

Detailed Explanation

Bituminous mixes can exhibit three different types of behavior depending on temperature and load conditions. Elastic behavior means that the material can return to its original shape after being deformed, while viscous behavior results in permanent deformation. Viscoelastic behavior represents a blend of these two: the material can recover over time, which is crucial for applications where stretches happen over long periods.

Examples & Analogies

Think of bending a metal wire; when you bend it slightly, it returns to its original shape (elastic behavior) until you bend it too far. If you heat it up and bend it, it might hold the new shape (viscous behavior). Finally, rubber is a perfect example of viscoelastic behavior; it stretches out, regaining its shape slowly rather than instantly.

Fatigue Behavior of Bituminous Mixes

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fatigue failure is the progressive cracking of a pavement under repeated loads, even when each load is below the ultimate strength of the material.

Detailed Explanation

Fatigue behavior refers to how bituminous mixes can deteriorate over time due to continuous stress from vehicle traffic. Even if each individual load (like a passing car) doesn’t cause failure on its own, the accumulation of these loads can lead to cracking. This gradual failure is crucial for engineers to consider in pavement design to prevent premature failures.

Examples & Analogies

Consider a small piece of wire that bends each time you pull it. If you only pull it lightly, it won’t break immediately; however, over time, the repeated bending will weaken it, leading to a break. This mirrors how repeated traffic loads weaken roads and can lead to cracking.

Laboratory Fatigue Testing

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Beam Fatigue Test (Repeated Flexural Bending).

• Indirect Tensile Fatigue Test.

• Test results are used to plot fatigue life curves (strain vs. number of cycles to failure).

Detailed Explanation

In laboratory settings, engineers conduct specific tests to evaluate how bituminous mixes will perform under fatigue. The Beam Fatigue Test and Indirect Tensile Fatigue Test help to simulate the effects of traffic and determine how long the materials will last before developing cracks. The results from these tests are represented graphically to show the relationship between strain and the number of load cycles until failure occurs, which is essential for predicting the durability of road materials.

Examples & Analogies

Imagine testing several strands of yarn by pulling and releasing them repeatedly to see which one frays first. The tests performed in labs are much like this, helping engineers understand how long the materials can withstand consistent stress from traffic before showing signs of weakening.

Key Concepts

-

Stress-Strain Behavior: The response of bituminous mixes to applied loads influenced by temperature and loading rate.

-

Fatigue Behavior: The tendency of pavement to develop cracks due to repeated loads, significant for pavement longevity.

-

Creep: The increase in strain over time at constant stress, relevant in analyzing long-term deformations.

-

Rutting: Permanent deformation occurring in wheel paths, needing careful design consideration to prevent.

-

Dynamic Modulus: A measure of stiffness that is important for evaluating performance under repeated loading.

Examples & Applications

When a bituminous pavement is exposed to high temperatures, it may soften, exhibiting more viscous behavior, which is critical in understanding how it performs under heavy traffic.

After several overloads, you may observe alligator cracking, indicating fatigue failure, which could have been predicted through appropriate fatigue testing of the mix.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When loads are tight, and temps are right, bitumen stays light; elastic in sight.

Stories

Imagine a line of cars driving on a hot road. The pavement softens, and soon wheels leave behind tracks—this is the life of bituminous mixes responding to both pressure and heat.

Memory Tools

FARMS: Factors affecting rutting - Aggregate type, temperature, rutting test results, moisture, shear flow.

Acronyms

FATIGUE

Focusing on Aggregate

Temperature

Input load

Gradation

Upheaval

Environmental conditions.

Flash Cards

Glossary

- Bituminous Mixes

Composite materials primarily composed of asphalt binder and aggregates used in road construction.

- Viscoelastic Behavior

A property whereby materials exhibit both viscosity and elasticity, illustrating time-dependent strain recovery.

- Fatigue Cracking

Cracking that develops in pavements due to repeated loading conditions often below the ultimate strength of the material.

- Dynamic Modulus

A measure of the stiffness of a bituminous mix under cyclic loading, influenced by temperature and frequency.

- Rutting

Permanent deformation that occurs in wheel paths due to repeated loading, causing longitudinal depressions.

- Creep

The gradual increase in strain in a material when subjected to a constant load over time.

- Moisture Susceptibility

How susceptible a bituminous mix is to moisture-induced damage, affecting bond strength between aggregate and binder.

Reference links

Supplementary resources to enhance your learning experience.