Mechanism of Fatigue Cracking

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Fatigue Cracking Mechanism

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll be discussing the mechanism of fatigue cracking in bituminous mixes. Can anyone tell me what fatigue cracking means?

Is it when the pavement gets cracks over time because of too many cars driving over it?

Exactly! Fatigue cracking occurs due to repeated loads that can cause microcracks to form in the material. This progressive failure is a significant concern in pavement design. So, what do you think happens to those microcracks?

Do they eventually connect and form bigger cracks?

Yes! As they coalesce, they lead to observable cracking patterns like alligator or bottom-up cracking. Remember, the load magnitude and the number of loading cycles play a crucial role here.

How does temperature affect this?

Temperature affects the viscosity of the bituminous material, impacting its flexibility and ability to withstand repeated stresses. Let’s remember the acronym FATIGUE for factors influencing this process: *F*orces, *A*ggregate types, *T*emperature, *I*nterval of loads, *G*rade of asphalt, *U*niform mix design, and *E*nviromental conditions.

Got it! So, the material type really changes how it performs under stress!

That’s correct! Always remember, understanding these mechanisms can help us design better and more durable pavements.

Types of Fatigue Cracking

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s now discuss the different types of fatigue cracking. Can anyone name some?

I’ve heard of alligator cracking!

Right! Alligator cracking normally appears in interconnected patterns. What about bottom-up cracking?

That’s when it starts from the bottom and goes up, isn’t it?

Exactly! In bottom-up cracking, the defects propagate upwards through the pavement layers. These cracks can allow water to enter the underlying layers, causing more damage. How do you think we can identify these cracks?

Maybe through visual inspections?

Yes, visual inspections are key! We also use laboratory tests to simulate conditions that lead to these cracks. Remember, the severity of cracking can be influenced by traffic load and environmental factors like temperature changes.

It sounds like we need to be proactive in our approaches to maintenance!

Absolutely! Being proactive is essential to prolonging the pavement's service life.

Testing for Fatigue Cracking

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's dive into the laboratory testing for fatigue cracking. Who can think of a common test we might use?

Could it be the Beam Fatigue Test?

Exactly! The Beam Fatigue Test simulates repeated flexural bending to measure how the mix holds up under load. What else do we measure during fatigue testing?

The number of cycles to failure?

Yes! And plotting fatigue life curves helps us assess the performance over time. Understanding these tests is crucial for predicting how the pavement will behave under real-world conditions.

So these tests help engineers design better pavements?

Absolutely! They provide insights that lead to improved mix designs and enhanced durability. Always remember: Testing leads to knowledge, and knowledge leads to better pavement!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores the mechanism of fatigue cracking in bituminous mixes, detailing how repeated load applications cause microcracks that develop into visible fatigue cracks, such as alligator or bottom-up cracking. Understanding these mechanisms is crucial for improving the lifespan and efficacy of flexible pavements.

Detailed

Mechanism of Fatigue Cracking

Fatigue cracking is a critical failure mode of asphalt pavements, characterized by the progressive cracking that appears under repeated loading conditions even if each individual load is below the material's ultimate strength. This section discusses:

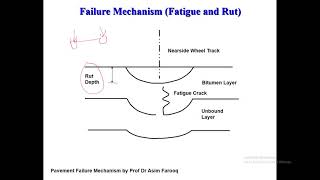

- Microcrack Formation: Continuous applications of repetitive loads lead to the initiation of microcracks within the bituminous mix. Over time, these microcracks grow in size and may merge, leading to more significant fatigue cracks.

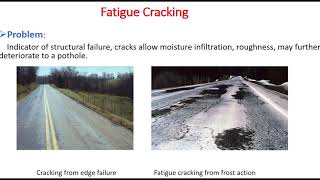

- Types of Fatigue Cracking: The most commonly observed forms of fatigue cracking are alligator cracking, which manifests as interconnected cracks resembling an alligator's skin, and bottom-up cracking, where cracks start at the pavement's lower layers and propagate upwards.

- Significance: Understanding the mechanism of fatigue cracking is vital as it directly impacts pavement performance, safety, and longevity. This knowledge informs mix design practices and maintenance strategies aiming to enhance the resistance to fatigue.

- Diagnostics and Testing: Various laboratory tests simulate fatigue conditions to analyze mix performance over time and predict the expected fatigue life of the pavement.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Microcrack Formation

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Repeated load applications cause microcracks that coalesce into visible fatigue cracks.

Detailed Explanation

When a pavement is subjected to repeated loads, like the weight of vehicles passing over it, tiny fractures known as microcracks begin to form in the material. These microcracks are often too small to be seen at first, but they indicate the initial stages of damage. Over time, as more loads are applied, these microcracks grow and start to connect or merge into larger cracks. This process is called coalescence, which eventually leads to visible fatigue cracks on the pavement surface.

Examples & Analogies

Think of it like a piece of glass. If you lightly tap a glass repeatedly, tiny cracks may start to form that are not immediately visible. Over time, if you keep tapping, those small cracks can grow and connect, resulting in a larger break. Similarly, in pavements, repeated traffic loads create tiny cracks that can lead to larger, visible cracks.

Types of Fatigue Cracking

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

This leads to alligator cracking or bottom-up cracking.

Detailed Explanation

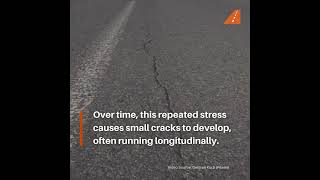

As the microcracks evolve into larger cracks, they can manifest in specific patterns. Alligator cracking, also called bottom-up cracking, resembles the scales of an alligator due to its interconnected, polygonal shapes. This type of cracking often initiates from the bottom of the pavement layer due to high stress from traffic loads and progressively moves upward. It is a clear indicator of fatigue failure, showing that the pavement can no longer withstand the repeated stresses placed upon it.

Examples & Analogies

Imagine a cookie that has cracks all over its surface from being over-baked. Just as the cookie gets brittle and cracks from stress, a pavement can develop alligator cracking when it has been under repetitive pressure from heavy vehicles, showing that it's reached its limits.

Key Concepts

-

Fatigue Cracking: An important failure mode in asphalt pavements due to repeated loading.

-

Microcrack Formation: Small cracks that develop from continuous load applications.

-

Alligator and Bottom-up Cracking: Two primary types of fatigue cracks characterized by their initiation and propagation patterns.

-

Laboratory Testing: Critical methods to assess the fatigue life of bituminous mixes.

Examples & Applications

Alligator cracking can often be seen in older pavements that have experienced significant traffic load over time.

Bottom-up cracking might cause larger structural issues if not identified early, as water may infiltrate and damage the lower pavement layers.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When the road cracks and they grow, fatigue's the reason we know.

Stories

Imagine a busy road where cars drive over and over; each time, tiny cracks form, and eventually, they grow into larger cracks that need repair.

Memory Tools

F A T I G U E - Forces, Aggregate, Temperature, Interval, Grade, Uniform, Environmental.

Acronyms

FATIGUE - Remember it as the factors causing fatigue in pavements.

Flash Cards

Glossary

- Fatigue Cracking

The progressive cracking of pavement due to repeated loads, which can lead to visible cracks without exceeding the ultimate strength.

- Microcracks

Small initial cracks formed in the pavement material as it experiences repetitive loading.

- Alligator Cracking

A type of fatigue cracking that appears as interconnected cracks resembling an alligator's back.

- Bottomup Cracking

Cracks that initiate from the pavement's lower layers and propagate upwards.

Reference links

Supplementary resources to enhance your learning experience.