Thermal Cracking

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Thermal Cracking

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into thermal cracking, which specifically affects bituminous mixes in colder climates. Can anyone tell me what they think causes thermal cracking?

Is it because of the temperature changes?

Exactly! As the temperature drops, the bituminous mix contracts. This thermal contraction creates stresses that can lead to cracking if they exceed the material's tensile strength. Let's remember it as a 'cold snap' effect.

So, is thermal cracking worse in certain types of bituminous mixes?

Good question! Yes, the composition and properties of the mix can influence its susceptibility to thermal cracking.

Low-Temperature Fracture Toughness

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's explore low-temperature fracture toughness. Why do we measure it, and how do we go about it?

Do we measure it to see how the mix will perform in the cold?

Exactly right! We want to understand how the mix will behave at low temperatures. We use tests like the SCB and DCT. These tests help us determine how likely it is for cracks to form.

What does the term 'fracture energy' mean in this context?

Great question! Fracture energy, or Gf, quantifies the energy required to create a new surface in the material, directly relating to its toughness against crack propagation.

Mechanisms of Crack Propagation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now onto how cracks actually form and grow in bituminous mixes. Can anyone share their thoughts on this process?

Do they start at specific points, like air bubbles?

Yes! Cracks often initiate at flaws or air voids within the mix. Once they start, their growth depends on how much energy can be dissipated on applying stress.

What happens if the energy dissipation isn't sufficient?

If there's insufficient energy dissipation, the cracks can continue propagating, potentially leading to significant pavement damage. This concept underscores the importance of understanding the mechanics of thermal cracking.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses thermal cracking as a significant issue for bituminous mixes in cold climates, focusing on its causes, the mechanics of low-temperature fracture toughness, and how cracks propagate through the material. It emphasizes the importance of understanding these processes to enhance the durability and performance of pavement structures.

Detailed

Thermal Cracking

Thermal cracking occurs in bituminous mixes primarily in cold climates, where the significant contraction of the mix leads to stresses that exceed the material's tensile strength. This section explores key aspects of thermal cracking, including:

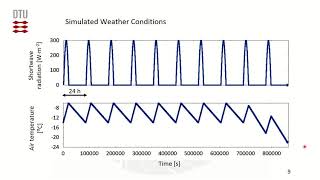

- Causes of Thermal Cracking: This phenomenon is primarily due to the thermal contraction of bituminous materials when subjected to low temperatures.

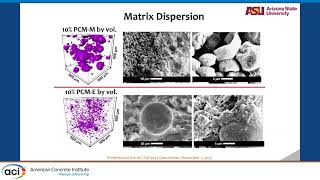

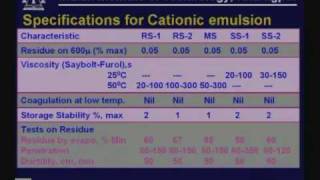

- Low-Temperature Fracture Toughness: Essential in determining how susceptible a bituminous mix is to crack initiation and propagation. Testing methods like the Semi-Circular Bend (SCB) and Disk-Shaped Compact Tension (DCT) are used to evaluate this toughness.

- Crack Propagation Mechanisms: Discusses how cracks initiate at existing flaws or air voids in the mix and propagate when there isn't enough energy dissipation to resist these stresses. Fracture energy (Gf) serves as a metric for analyzing resistance against these processes.

Understanding the thermal cracking behavior of bituminous mixes is vital for enhancing pavement design and ensuring long-lasting road performance.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Thermal Cracking Overview

Chapter 1 of 1

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Occurs in cold climates due to thermal contraction of the mix.

Detailed Explanation

Thermal cracking is a type of distress that happens when the temperature drops significantly, causing the bituminous mix in pavements to contract. This contraction can lead to cracks forming, especially in colder climates where such temperature fluctuations are common. Essentially, the material shrinks as it cools, and if the contraction is too much for the material to handle, cracks will initiate and develop.

Examples & Analogies

Imagine a rubber band on a cold day. When you pull it, it stretches. But as it gets colder, the rubber band becomes rigid and can snap if stretched too far. Similarly, when pavement materials are subjected to low temperatures, they contract. Just like the rubber band, bituminous mixes can develop cracks when they become too stiff and are unable to absorb the changes.

Key Concepts

-

Thermal Cracking: Cracking due to thermal contraction at low temperatures.

-

Fracture Toughness: Measurement of resistance to crack initiation and propagation.

-

Crack Propagation: The mechanism by which cracks grow under stress.

Examples & Applications

In an area with severe winter conditions, asphalt pavements often exhibit thermal cracking, especially if not designed with sufficient low-temperature flexibility.

A study showed that different asphalt mixtures can lead to varying levels of resistance against thermal cracking, indicating the importance of mix design.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cold days make mixes shrink, crack it will, that's its link.

Stories

Once upon a winter's night, asphalt shrank and cracked, causing a slippery plight.

Memory Tools

Think of 'COLD' - Cracking, On Low Degrees, helps remember how temperature impacts asphalt.

Acronyms

C-T-C

Cold-Temperature Cracking = Causes

Tests

Consequences.

Flash Cards

Glossary

- Thermal Cracking

Cracking in bituminous materials resulting from thermal contraction in cold environments.

- Fracture Toughness

The ability of a material to resist crack propagation.

- Fracture Energy (Gf)

The energy required to create new surfaces within a material during cracking.

- SemiCircular Bend (SCB)

A laboratory test used to evaluate the low-temperature fracture toughness of bituminous mixes.

- DiskShaped Compact Tension (DCT)

Another test method for assessing the fracture toughness of materials, particularly at low temperatures.

Reference links

Supplementary resources to enhance your learning experience.