Low-Temperature Fracture Toughness

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Low-Temperature Fracture Toughness

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will delve into low-temperature fracture toughness. Why do you think it's crucial for bituminous mixes, especially in cold climates?

I think it's important because we need the asphalt to be strong and not crack when it gets cold.

Exactly! When temperatures drop, bituminous materials can become brittle. This stiffness can lead to cracks. Let's remember this with the acronym 'CRACK' – Cold Resilience and Ability to Compensate Kinetics. What can happen if these materials fail to resist cracks?

The pavement might break down faster, leading to potholes or other issues.

Right! And cracks can emerge from flaws in the material. Thus, evaluating the fracture toughness is vital.

Testing Methods for Low-Temperature Fracture Toughness

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

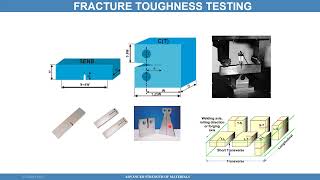

Let's discuss how we actually measure low-temperature fracture toughness. We use two tests: the Semi-Circular Bend and Disk-Shaped Compact Tension. Who can describe their purpose?

I think they help us see how well the asphalt can handle low temperatures without cracking.

Correct! The SCB test determines fracture toughness by bending a semi-circular sample. Can anyone tell me how the DCT is different?

The DCT uses a disk-shaped sample, right? It tests the material under tension.

Exactly! Both tests help us understand the material's resistance to crack propagation. Remember this with 'BEND'—Bending Evaluation of Notable Durability.

Significance of Evaluating Fracture Toughness

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Why is evaluating fracture toughness important for engineers and designers when selecting materials for pavements?

It helps them choose mixes that will last longer and perform well in cold weather!

Yes! Choosing mixes with optimal fracture toughness can lead to safer and more durable pavements. How might low toughness affect maintenance costs?

If the pavement cracks often, it would require more repairs, increasing costs!

Exactly! 'COSTS' - Cracks Often Sew Trouble and Stresses. This importance underscores why we emphasize testing methods in design practices.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Low-temperature fracture toughness is a critical property of bituminous mixes that helps assess their ability to resist crack initiation and propagation under low-temperature conditions. The section highlights the testing methods like Semi-Circular Bend (SCB) and Disk-Shaped Compact Tension (DCT) used to determine fracture toughness and their implications for pavement performance.

Detailed

Detailed Summary

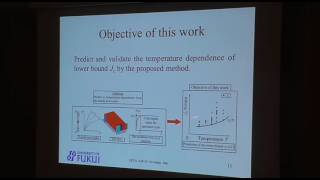

Low-temperature fracture toughness is essential for evaluating how bituminous mixes behave in cold environments, where they are susceptible to cracking due to thermal contraction. This section emphasizes the importance of understanding fracture toughness for ensuring pavement longevity and reliability. Two primary tests— the Semi-Circular Bend (SCB) test and the Disk-Shaped Compact Tension (DCT) test—are outlined, explaining how they measure the mix's ability to withstand fracture under stress without developing critical damage. These assessments are crucial for predicting cracking, especially in colder climates, consequently influencing material selection and pavement design strategies.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Testing Methods for Low-Temperature Fracture Toughness

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Determined using tests like Semi-Circular Bend (SCB) and Disk-Shaped Compact Tension (DCT).

Detailed Explanation

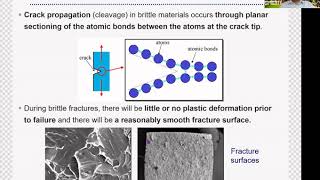

Low-temperature fracture toughness refers to the ability of bituminous mixes to resist fracturing when the temperature is low. This property is significant in ensuring that pavements do not develop cracks during cold weather. To evaluate this property, two primary testing methods are commonly used: the Semi-Circular Bend (SCB) test and the Disk-Shaped Compact Tension (DCT) test.

- Semi-Circular Bend (SCB) Test: This test involves creating a semi-circular specimen of the bituminous mix. The specimen is then subjected to a load until it fractures. The fracture energy required gives insight into the material's resistance to cracking under low temperatures.

- Disk-Shaped Compact Tension (DCT) Test: Similar to the SCB test, this method involves a disk-shaped sample. The test measures how much force is needed to create a crack in the sample, which helps in understanding its fracture toughness.

Both tests provide valuable data for predicting how the bituminous mix will behave in cold weather conditions.

Examples & Analogies

Think of a water bottle filled with water and then placed in a freezer. When the water freezes, it expands and could potentially crack the bottle if the plastic is brittle enough. Similarly, the bituminous mix needs to withstand low temperatures without cracking, and using these tests helps determine if the mix is strong enough, just like checking if a water bottle can handle freezing temperatures.

Significance of Fracture Toughness in Pavement

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Fracture energy (Gf) is used as a metric for resistance.

Detailed Explanation

The concept of fracture toughness is critical in the design and evaluation of pavements. Fracture energy, denoted as Gf, quantifies how much energy is needed to propagate a crack in the material. The higher the Gf value, the more resistant the pavement is to cracking when exposed to low temperatures. This ability to absorb energy before failing is crucial for maintaining the integrity and longevity of pavements in cold climates. When engineers design roadways, they consider fracture toughness as a key metric to ensure that the materials they select can handle the stresses and strains caused by environmental factors, particularly freezing temperatures.

Examples & Analogies

Consider a rubber band. If you pull it apart slowly, it stretches; however, if you yank it too hard, it snaps. The energy absorbed by the rubber band before it breaks can be compared to fracture energy. A rubber band that stretches a lot before snapping would represent a material with high Gf, indicating better resistance to cracking, just as pavements with high fracture toughness are better equipped to handle the strains of changing temperatures.

Key Concepts

-

Low-Temperature Fracture Toughness: The capacity of bituminous mixes to withstand cracking at low temperatures.

-

SCB Test: A method to evaluate the fracture toughness by bending a semi-circular test specimen.

-

DCT Test: A tension-based method for assessing fracture toughness with a disk-shaped specimen.

Examples & Applications

Example 1: A new asphalt mix designed for use in cold climates is tested using the SCB test to ensure it has adequate fracture toughness to prevent thermal cracking.

Example 2: When evaluating different types of bitumen, the DCT test results indicate which materials are more resilient against crack propagation under low-temperature conditions.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When the temperature drops, materials may crack, So test their toughness, keep them on track.

Stories

Imagine a winter road where a driver hits a pothole. That pothole appeared due to cracked bitumen from freezing temps; if only the pavement had been tested for fracture toughness!

Memory Tools

Remember 'CRACK' for Cold Resilience and Ability to Compensate Kinetics.

Acronyms

Use 'BEND' to recall Bending Evaluation of Notable Durability.

Flash Cards

Glossary

- Fracture Toughness

The ability of a material to resist crack propagation when subjected to stress.

- SemiCircular Bend (SCB)

A test method used to measure the fracture toughness of bituminous mixes by applying a bending force.

- DiskShaped Compact Tension (DCT)

A testing method that evaluates the fracture toughness of materials under tensile stress.

- Crack Propagation

The growth of a crack in a material under applied stress.

- Thermal Contraction

The reduction in size or volume of a material as the temperature decreases, potentially leading to cracking.

Reference links

Supplementary resources to enhance your learning experience.