Mechanism of Rutting

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Rutting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing rutting, which is a significant issue in flexible pavements. Rutting is the permanent deformation that occurs along the wheel paths. Can anyone tell me why this is important?

It affects the driving experience and can be dangerous for vehicles if the ruts are deep.

Exactly! It reduces safety and may lead to higher maintenance costs. Let's also remember the acronym 'D-S-C-T' for the factors influencing rutting such as Densification, Shear flow, Compaction quality, and Temperature.

What causes densification in asphalt mixes?

Great question! Densification occurs when the asphalt mix is subjected to repeated loads, which can compress the aggregates and the binder.

Factors Influencing Rutting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's dive deeper into the factors influencing rutting. There are several important aspects such as binder type. Can someone explain how the binder type affects rutting?

Different types of binders might perform better at certain temperatures, which means they'll resist rutting differently.

Exactly! It's about the material's properties and how they respond under heat and stress. Remember, 'B-A-C-T' for Binder, Aggregate gradation, Compaction quality, and Temperature - these all play a role.

So, better materials mean less possibility of rutting?

Correct! Higher quality materials combined with good compaction yield better results.

Testing for Rutting Resistance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

What methods do we have for testing rutting resistance in asphalt pavements?

I've heard about the Wheel Tracking Test. How does that work?

The Wheel Tracking Test, like the Hamburg Wheel Tracking Test, simulates the loading conditions that asphalt surfaces face under traffic. Does anyone know another testing method?

The Repeated Load Triaxial Test, right?

Correct! These tests are essential in determining how well our mixes will hold up under real-world conditions.

So these tests can help us understand how to mitigate rutting?

Absolutely! Testing helps us design better pavements and choose materials that resist deformation.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The mechanism of rutting involves densification and shear flow in bituminous mixes, particularly at elevated temperatures. Understanding these mechanisms is crucial for improving asphalt performance and longevity under repetitive loading conditions.

Detailed

Mechanism of Rutting

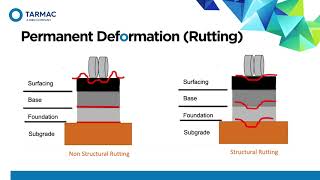

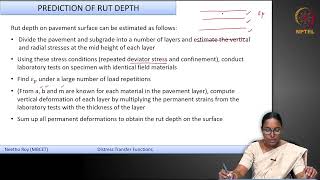

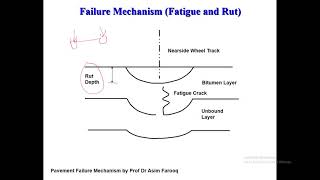

Rutting in flexible pavements is primarily characterized by a permanent deformation or depression that occurs in the wheel paths, resulting from accumulated stress due to traffic loads over time. The underlying mechanisms contributing to rutting involve two key processes: densification and shear flow within the asphalt mix.

Key Factors Affecting Rutting

Rutting is notably more prevalent at higher pavement temperatures, where the bituminous materials become more malleable, leading to greater susceptibility to deformation. Factors influencing the rutting mechanism include:

- Binder Type and Grade: Different binder materials exhibit varying levels of resistance to deformation, affecting the pavement's durability.

- Aggregate Gradation and Angularity: The physical characteristics of the aggregates, including size distribution and shape, play a critical role in the mix's stability under stress.

- Compaction Quality: Proper compaction during construction is vital to achieving a dense asphalt layer that resists deformational flow.

- Pavement Temperature and Thickness: External temperature influences the viscosity of the asphalt, whereas thickness may determine the layer's ability to distribute loads effectively.

Understanding these mechanisms is essential for engineers and designers in selecting appropriate materials and designs for sustainable pavement structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Cause of Rutting

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Caused by densification and shear flow in the mix.

Detailed Explanation

Rutting occurs in pavement when there is permanent deformation in the surface layer. This is mainly due to two processes: densification and shear flow. Densification refers to the compacting of the material under repeated loads, which compresses the mixture and reduces its volume. Shear flow is when the materials within the asphalt mix start to move or flow under pressure, which often happens in warmer conditions. Together, these two processes lead to the formation of ruts in the surface of the pavement.

Examples & Analogies

Imagine stepping into a soft piece of wet clay. The more you step on it, the more compacted and less voluminous it becomes, forming impressions. Similarly, in pavement, with heavy traffic, the repeated weight compresses the asphalt and causes it to deform, leading to rutting.

Conditions for Rutting to Occur

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Dominant at high pavement temperatures.

Detailed Explanation

Rutting is particularly prevalent in warmer temperatures. This is because high temperatures cause the bitumen in the asphalt mix to soften. When the surface temperature rises, the material's viscosity decreases, making it less viscous and more prone to flow under stress. Consequently, roads under heavy traffic and high temperatures are more likely to experience significant rutting.

Examples & Analogies

Think of a hot day when asphalt roads feel soft underfoot. If you were to drag your foot across the surface, you would create a groove. Roads behave similarly when heated; the soft asphalt cannot retain its shape under the weight of vehicles, leading to depressions or ruts.

Key Concepts

-

Rutting: The permanent deformation in pavements due to traffic loads.

-

Densification: The process of reducing air voids in asphalt mixes through compaction.

-

Shear Flow: Deformation caused in asphalt mixes primarily at elevated temperatures.

-

Binder Quality: The importance of material choice in preventing rutting.

-

Compaction Quality: How well the asphalt has been compacted impacts its resistance to deformation.

Examples & Applications

A highway experiencing rutting on the wheel paths due to heavy truck traffic, particularly during warmer months.

An asphalt mix using a high-performance binder to prevent rutting when tested under replicable conditions in the lab.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Pavement's ruts can bring much strife, keep designs tough to sustain their life.

Stories

Imagine a busy road where trucks drive daily. Over time, the repeated weight compacts the asphalt, creating grooves or ruts where wheels touch. Just like a path gets worn, the asphalt needs strong materials to withstand the journey of years!

Memory Tools

Remember 'D-S-C-T' to recall Densification, Shear flow, Compaction quality, and Temperature.

Acronyms

Use 'B-A-C-T' - Binder, Aggregate gradation, Compaction quality, Temperature to discuss factors influencing rutting.

Flash Cards

Glossary

- Rutting

Permanent longitudinal depression in the wheel paths of pavements due to accumulated deformation from repeated loads.

- Densification

Compaction of asphalt mix resulting from repeated loading, which reduces air voids and increases density.

- Shear Flow

The movement of asphalt mixes exacerbated by heat, causing deformation under traffic loads.

- Binder

The adhesive substance in bituminous mixes that coats aggregate particles, providing cohesion.

- Compaction Quality

The degree to which asphalt mixes are compacted, impacting their strength and performance.

- Aggregate Gradation

The distribution of different-sized aggregate particles in a bituminous mix, affecting its mechanical behavior.

Reference links

Supplementary resources to enhance your learning experience.