Mechanistic-Empirical Pavement Design

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

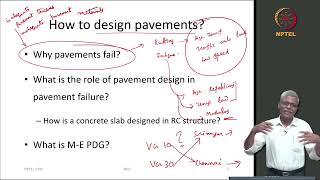

Overview of Mechanistic-Empirical Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re diving into Mechanistic-Empirical Pavement Design. Can anyone tell me what mechanistic design refers to?

Isn't it based on the physical behavior of materials under loads?

Exactly, Student_1! It considers how materials deform under stress. Now, what does ‘empirical’ imply in this context?

It refers to using data or observations from real-world pavements.

Correct, Student_2! By combining both, we improve our predictions for pavement performance. Remember, it's like blending science with practical observations.

So, we use models and data together?

Right! We utilize distress models to specifically anticipate issues like fatigue and rutting. Can anyone give me an example of a distress model?

Fatigue cracking models?

Yes! Very good, Student_4! In summary, Mechanistic-Empirical Design significantly enhances our ability to create durable pavements.

Distress Models in Pavement Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Continuing from our last discussion, let's talk about the distress models used in this design. Why do you think they are crucial?

They help predict when a pavement will fail.

Exactly, Student_1! And what types of distress do we focus on?

Fatigue, rutting, and thermal cracking?

Correct! These are critical to ensure the pavement can withstand expected loads. Let’s think about fatigue cracking—what causes it?

Repeated loads that create micro-cracks leading to larger cracks?

Yes! Student_3, you're spot on! Can anyone suggest why knowing this is beneficial for engineers?

It helps in designing better pavements to extend their lifespan.

Great insight, Student_4! Remember, the goal is to minimize maintenance costs and maximize safety for drivers.

Predicting Pavement Performance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s cover how we predict the performance of pavements using this integrated design. What tools or methods do you think might be used?

Field data collection and computer simulations?

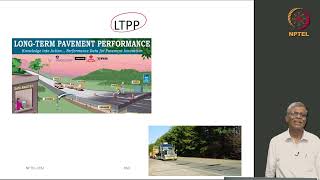

Exactly! We combine field data to calibrate our models properly. What’s the advantage of using field data?

It reflects real-life conditions and problems pavements face.

Spot on, Student_1! By integrating real-world performance data, we tailor our models to be more accurate, ensuring better outcomes.

So, it’s like refining a recipe based on feedback?

Perfect analogy, Student_4! In summary, using Mechanistic-Empirical methods leads us to smarter and more durable pavement designs.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

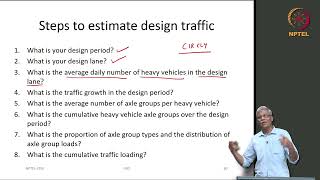

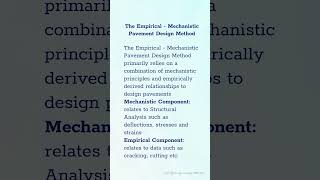

This section discusses the Mechanistic-Empirical Pavement Design method, which combines mechanistic modeling approaches with empirical calibrations derived from field data. It focuses on using distress models to predict pavement failure due to fatigue, rutting, and thermal cracking, thus contributing significantly to intelligent pavement engineering.

Detailed

Mechanistic-Empirical Pavement Design

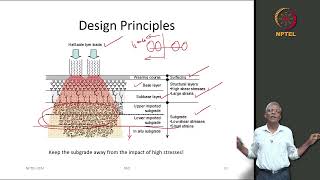

Mechanistic-Empirical Pavement Design is a sophisticated approach that integrates mechanical principles with empirical data to effectively predict the behavior of bituminous mixes under varying traffic loads and environmental conditions. The section emphasizes the importance of combining mechanistic models—representing the physical behavior of materials—with empirical calibration, which uses real-world data gathered from field performance. By employing distress models covering key issues such as fatigue cracking, rutting, and thermal cracking, this method provides a comprehensive framework for designing pavements that can withstand anticipated stressors. The significance of using this integrated design approach lies in its ability to enhance the durability and longevity of pavement structures, leading to improved safety and reduced maintenance costs.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Mechanistic-Empirical Design

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Combines mechanistic models with empirical calibration from field data.

Detailed Explanation

Mechanistic-Empirical Pavement Design combines two methodologies: mechanistic modeling and empirical calibration. Mechanistic models focus on the physical response of pavement materials under stress and loading, while empirical calibration involves adjusting these models based on observed performance data collected from the field. This combination helps to create a more accurate representation of how pavements will perform in real-world conditions.

Examples & Analogies

Think of this approach like baking a cake. The mechanistic part is like following a recipe perfectly, while the empirical part is adjusting the recipe based on previous cakes you've baked—perhaps you learned that a little more sugar or a different baking time results in a better cake!

Use of Distress Models

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Uses distress models for fatigue, rutting, and thermal cracking.

Detailed Explanation

Distress models predict specific types of pavement failures, such as fatigue cracking (which is caused by repetitive loading), rutting (permanent deformations under load), and thermal cracking (caused by temperature changes). By integrating these models, engineers can anticipate how different conditions and loads may lead to various distress types over time, allowing for more effective pavement design and maintenance plans.

Examples & Analogies

Imagine you're a doctor diagnosing a patient. You might use information about their symptoms (like fatigue or pain) and their medical history (like past illnesses) to predict potential health issues. Similarly, engineers use distress models to foresee and address possible pavement problems before they occur.

Key Concepts

-

Mechanistic-Empirical Design: An integration of mechanistic models with empirical data for enhanced pavement performance.

-

Distress Models: Predictive models used to forecast separate types of pavement failures.

Examples & Applications

Using field data from existing pavements to calibrate the fatigue models to ensure accurate predictions.

Applying mechanistic models to simulate the effect of different traffic loads on pavement structures.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To keep the roads nice and wide, use models and data as your guide.

Stories

Imagine engineers studying old roads; they collect data like detectives to understand when cracks unfold.

Memory Tools

MAP: Mechanistic models, Actual Performance data.

Acronyms

DEAR

Design with Empirical And mechanistic data for roads.

Flash Cards

Glossary

- MechanisticEmpirical Design

A pavement design methodology that integrates mechanistic models of material behavior with empirical data from field observations.

- Distress Models

Models that predict specific types of pavement failure, such as fatigue cracking and rutting.

Reference links

Supplementary resources to enhance your learning experience.