Fatigue Behavior of Bituminous Mixes

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Factors Affecting Fatigue Life

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

What do you think influences the fatigue life of bituminous mixes?

I think it relates to the mix design parameters like air voids and binder content.

Correct! Air voids, binder content, and the type of aggregate are crucial mix design parameters. Environmental conditions, such as temperature cycles and moisture, also play significant roles. Remember 'MELT' - Mix, Environment, Load, Time.

And what about the loading conditions? How do they influence fatigue?

Great question! Load magnitude, frequency, and rest periods affect how quickly fatigue damage develops. Higher loads and lesser rest lead to more rapid degradation.

Laboratory Fatigue Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s talk about laboratory fatigue testing methods. What methods can we employ to evaluate fatigue in bituminous mixes?

I recall the Beam Fatigue Test and the Indirect Tensile Fatigue Test.

Precisely! The Beam Fatigue Test simulates wheel loads through repeated flexural bending. In contrast, the Indirect Tensile Test evaluates the specimen’s performance under indirect loading. Can anyone remind me how we use these results?

They help create fatigue life curves to understand the relationship between strain and cycles to failure.

Exactly! These curves are critical for ensuring the longevity and performance of pavement structures. Always keep in mind the significance of testing!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The fatigue behavior of bituminous mixes entails the gradual cracking induced by repeated loads. This section elaborates on how microcracks develop into more prominent cracks and discusses various factors affecting the fatigue life of the mixes, such as mix design and environmental conditions. Laboratory testing methods used to evaluate fatigue behavior are also introduced.

Detailed

Fatigue Behavior of Bituminous Mixes

Fatigue failure is a critical concern for the sustainability of pavement structures, characterized by the progressive cracking of bituminous mixes under repeated loads that are safely below the material's ultimate strength. This section covers:

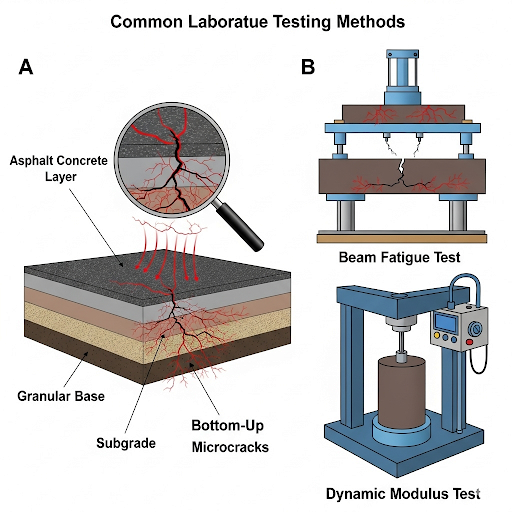

Mechanism of Fatigue Cracking

The initial response to repeated loading includes the formation of microcracks, which eventually coalesce into larger visible cracks, leading to phenomena like alligator cracking or bottom-up cracking.

Factors Affecting Fatigue Life

Several factors contribute to the fatigue life of bituminous mixes:

- Mix Design Parameters: The composition of the mix, including air voids, binder content, and aggregate type.

- Environmental Conditions: Temperature fluctuations and moisture levels significantly influence the material's performance.

- Load-Related Factors: The magnitude and frequency of applied loads, along with the duration of rest periods between load applications, play critical roles in fatigue development.

Laboratory Fatigue Testing Methods

Two primary testing procedures are utilized to assess the fatigue behavior of bituminous mixes:

- Beam Fatigue Test: This technique involves the repeated flexural bending of bituminous specimens to simulate wheel loading.

- Indirect Tensile Fatigue Test: This method assesses the fatigue resistance of specimens using indirect tensile loading.

The results of these tests are crucial for generating fatigue life curves, showcasing the relationship between strain and the number of cycles to failure, thereby aiding in effective pavement design and longevity.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Fatigue Failure

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fatigue failure is the progressive cracking of a pavement under repeated loads, even when each load is below the ultimate strength of the material.

Detailed Explanation

Fatigue failure refers to the gradual cracking that occurs in pavements due to the application of loads over time. It happens even when the intensity of each individual load is less than what the pavement could handle at once. This phenomenon underscores the importance of considering not just single heavy loads, but the cumulative effect of many lighter loads, such as those from vehicles driving over the pavement repeatedly.

Examples & Analogies

Imagine bending a metal coat hanger back and forth. Initially, it can withstand the stress without breaking, but after repeated bending, it becomes brittle and breaks at the point of most strain. Similarly, pavements can endure repeated traffic loads until tiny cracks form and eventually lead to significant failure even if each load didn't seem too heavy.

Mechanism of Fatigue Cracking

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Repeated load applications cause microcracks that coalesce into visible fatigue cracks.

• This leads to alligator cracking or bottom-up cracking.

Detailed Explanation

When loads are repeatedly applied to a pavement, tiny cracks called microcracks begin to form. Over time, these microcracks can merge, or coalesce, into larger, visible cracks on the surface of the pavement. The pattern that often results from this process is known as alligator cracking, which resembles the scales of an alligator. This type of cracking typically starts from the bottom of the pavement layer and works its way up, hence the term 'bottom-up cracking'.

Examples & Analogies

Think of a piece of clay that you repeatedly press down on. Initially, small indentations are left, but if you keep pressing, those small dents can grow larger and eventually crack the entire piece. Each press represents the repeated load on a pavement, leading from microcracks to larger, visible cracks.

Factors Affecting Fatigue Life

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Mix design parameters: air voids, binder content, aggregate type.

• Environmental conditions: temperature cycles and moisture.

• Load-related factors: load magnitude, frequency, and rest periods.

Detailed Explanation

The lifespan or durability of a pavement under repeated loads, known as fatigue life, is influenced by several critical factors. First, the mix design parameters such as the amount of air voids, the content of the binder, and the type of aggregates used can significantly impact how well the pavement can resist fatigue. Second, environmental conditions like changes in temperature and moisture can weaken the material, making it prone to cracking. Finally, the characteristics of the loads, including their magnitude, frequency (how often they occur), and the rest periods in between loads can affect how fatigue develops.

Examples & Analogies

Consider a rubber band. If you stretch it too much (magnitude) and keep pulling on it frequently without letting it return to its original shape (rest periods), it will eventually lose its elasticity and become brittle. Similarly, a pavement's design and environmental conditions will either support or significantly reduce its ability to cope with repetitive stress.

Laboratory Fatigue Testing

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Beam Fatigue Test (Repeated Flexural Bending).

• Indirect Tensile Fatigue Test.

• Test results are used to plot fatigue life curves (strain vs. number of cycles to failure).

Detailed Explanation

Laboratory testing is critical to assess the fatigue behavior of bituminous mixes. Two common tests are the Beam Fatigue Test and the Indirect Tensile Fatigue Test. In the Beam Fatigue Test, a sample is subjected to repeated bending to simulate traffic loads. The Indirect Tensile Fatigue Test assesses the sample's ability to resist static and dynamic loads by applying forces in a way that mimics real-world conditions. The results of these tests are used to create fatigue life curves, which graphically show the relationship between strain (deformation) and the number of load cycles until failure occurs.

Examples & Analogies

Think of baking cookies on a tray. If you repeatedly take the tray in and out of the oven (similar to load application), you'll eventually notice the tray warps or develops weak spots. Here, the baking represents the fatigue tests, showing how the cookie tray's material can cope with repeated temperature and handling stresses until it can no longer function properly.

Key Concepts

-

Fatigue Cracking: The progressive development of cracks due to repeated stress.

-

Microcracks: Small initial cracks leading to larger failures.

-

Fatigue Life: The overall durability of bituminous mixes under load.

Examples & Applications

In a study, pavement subjected to heavy traffic showed signs of alligator cracking after just a few seasons, demonstrating fatigue behavior.

Laboratory tests revealed that increasing binder content improved resistance to fatigue failure in asphalt mixes.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Fatigue will grow, as the loads apply, Microcracks form, soon they multiply.

Stories

Imagine a busy road where cars continuously drive over. At first, the road looks fine, but gradually tiny fractures appear. Over time, these little cracks grow big, just like how small worries can grow in our minds, leading to issues down the line.

Memory Tools

Remember 'LOAD' for fatigue factors - Load magnitude, Overall mix design, Atmospheric conditions, and Duration of rest.

Acronyms

Use 'MELT' to remember key factors affecting fatigue life - Mix, Environment, Load, Time.

Flash Cards

Glossary

- Fatigue Failure

The progressive cracking of a pavement under repeated loads, leading to material degradation.

- Microcracks

Small cracks that form within the material upon stress application, leading to larger cracks over time.

- Alligator Cracking

A pattern of interconnected cracks in pavement resembling an alligator's skin, typically resulting from fatigue failure.

- Fatigue Life

The total number of cycles a material can withstand before it shows signs of fatigue failure.

- Beam Fatigue Test

A laboratory method that applies repeated flexural loads to evaluate the fatigue resistance of bituminous mixes.

- Indirect Tensile Fatigue Test

A testing method that assesses the tensile strength of asphalt mixes under simulated traffic loading.

Reference links

Supplementary resources to enhance your learning experience.